Industrial three-dimensional edible fungus culture system

A three-dimensional cultivation, edible fungus technology, applied in cultivation, plant cultivation, mushroom cultivation and other directions, to achieve the effect of convenient water and healthy growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

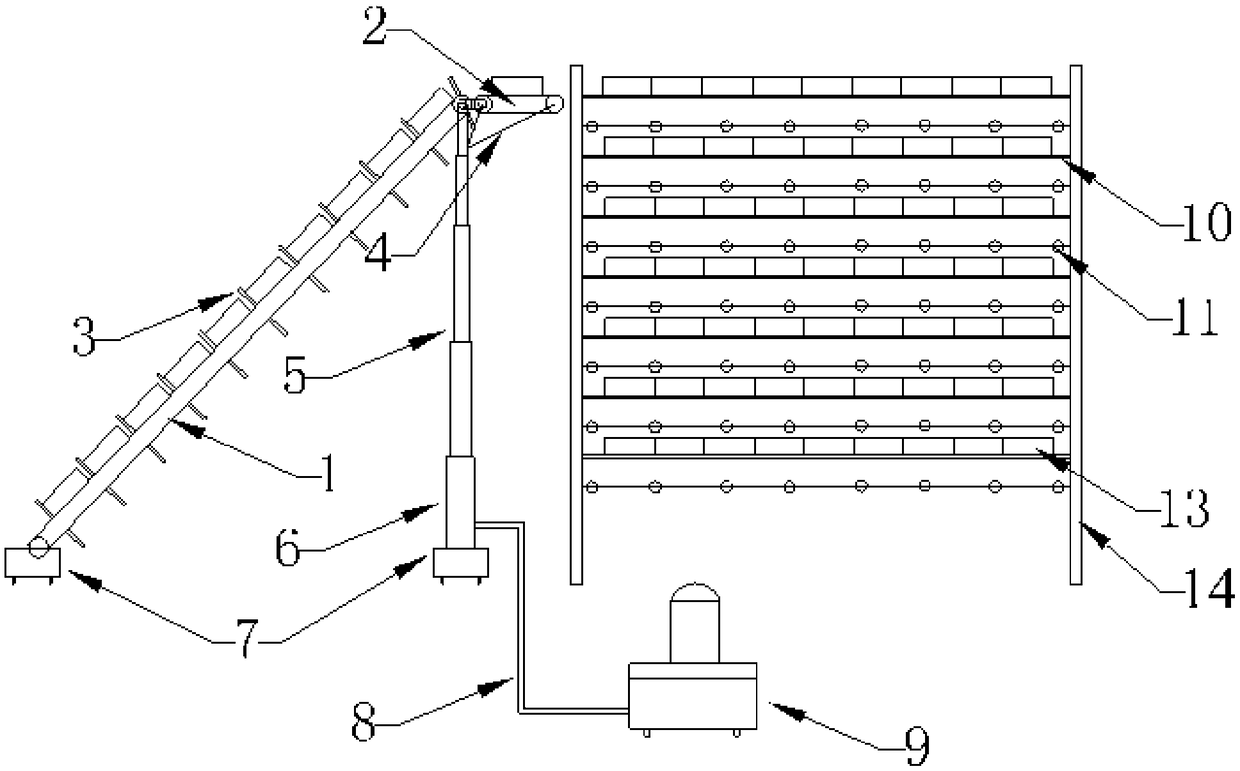

[0027] Specific implementation mode one, the following combination figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 10 Illustrate this embodiment, the edible fungus factory three-dimensional cultivation system, is characterized in that, it comprises multi-layer cultivation frame, bacteria brick placement layer, humidification layer and bacteria brick transmission unit;

[0028] The multi-layer cultivation frame is provided with a multi-layer carrier frame, and the bacteria brick placement layer and the humidification layer are alternately arranged on the multi-layer carrier frame; the bacteria brick transfer unit is used to transfer the bacteria bricks to each bacteria brick placement layer respectively The humidification layer is used to evenly spray water on the bacteria bricks on the adjacent bacteria brick placement layer to maintain its humidity.

[0029] The multi-layer cultivation frame includes four vertical poles 14 and a multi-layer carrier frame;

[003...

specific Embodiment approach 2

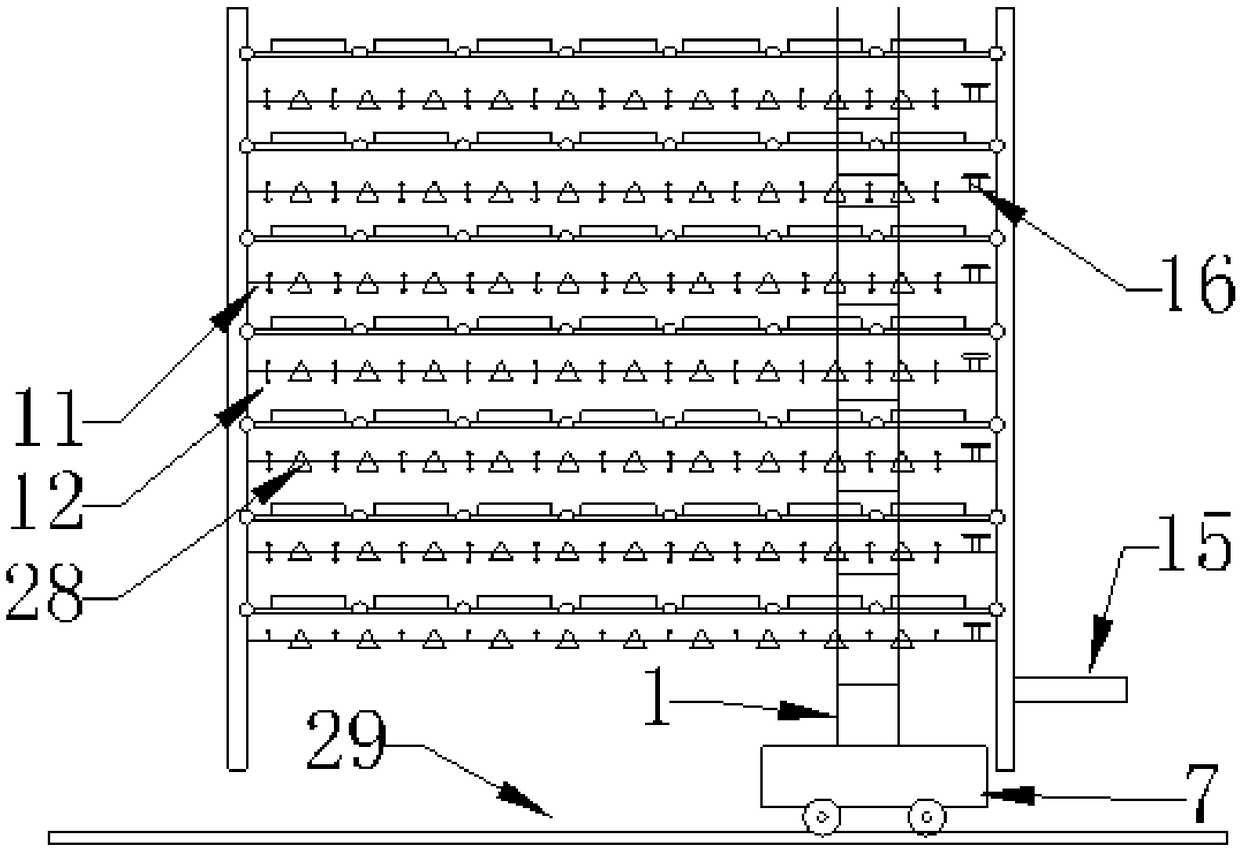

[0034] Specific implementation mode two, the following combination figure 2 This embodiment is described. The difference between this embodiment and Embodiment 1 is that each water pipe 11 is evenly distributed with a plurality of supplementary lights 28 , and the supplementary lights 28 and the atomizing nozzles 12 are arranged alternately.

[0035] The atomizing spray head 12 is a spray head in an upward water outlet direction and / or a downward water outlet direction.

[0036] The supplementary light 28 has a waterproof function, and the provision of the supplementary light 28 is beneficial for the staff to observe the state of the bacterial brick 13 .

[0037] The upward water outlet direction of the atomizing nozzle 12 is used to spray the bacteria bricks of the previous layer, and the downward water outlet direction is used to spray the bacteria bricks of the next layer.

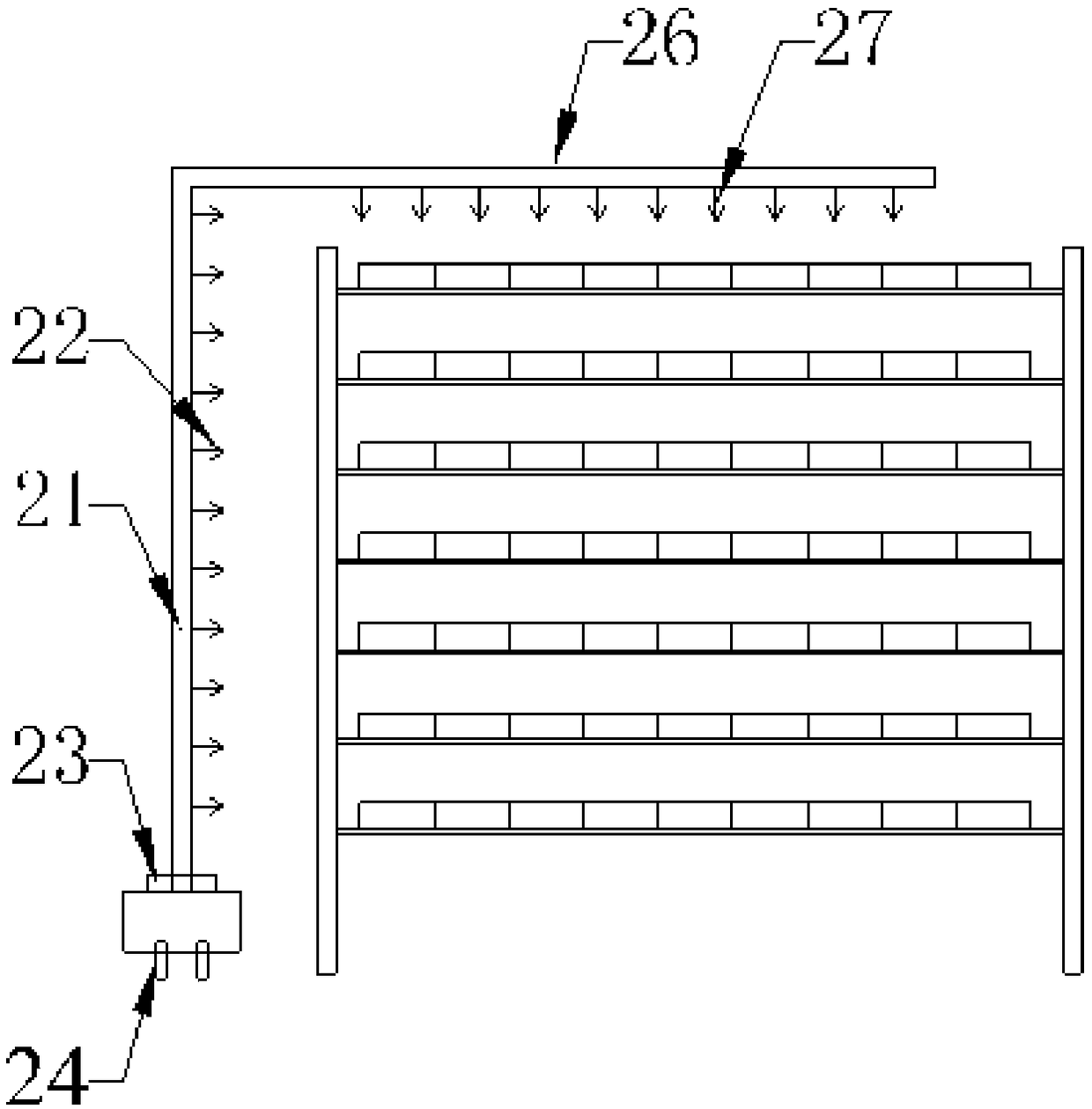

[0038] Humidification process: the water inlet of the water pipe is connected with an external wat...

specific Embodiment approach 3

[0039] Specific implementation mode three, the following combination Figure 5 to Figure 9 Describe this embodiment, the difference between this embodiment and Embodiment 2 is that the bacterial brick swing frame 10 includes a steel mesh support 20 and a stainless steel mesh 19, and the stainless steel mesh 19 is arranged in the middle hollow area of the steel mesh support 20;

[0040] N smooth vertical plates 30 are arranged in parallel along the length direction on the bacterial brick swing frame 10, and a bacterial brick movement groove is formed between two adjacent smooth vertical plates 30, which is used to assist the bacterial brick 13 on the bacterial brick swing frame 10. transmission.

[0041] In the middle of the bacteria brick pendant frame 10 is a stainless steel mesh 19, the size of the grid is determined according to the size of the fruiting body of the edible fungus, and cannot affect the growth of the fruiting body. The stainless steel net 19 is surrounded b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com