2d photonic crystal surface emission laser and method for producing same

一种二维光子晶体、面发光激光器的技术,应用在半导体激光器、激光器、声子激发器等方向,能够解决难以减小光点面积、很难减小光点面积高的光输出、激光波阵面紊乱等问题,达到加大强度、自由度变高、加大面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

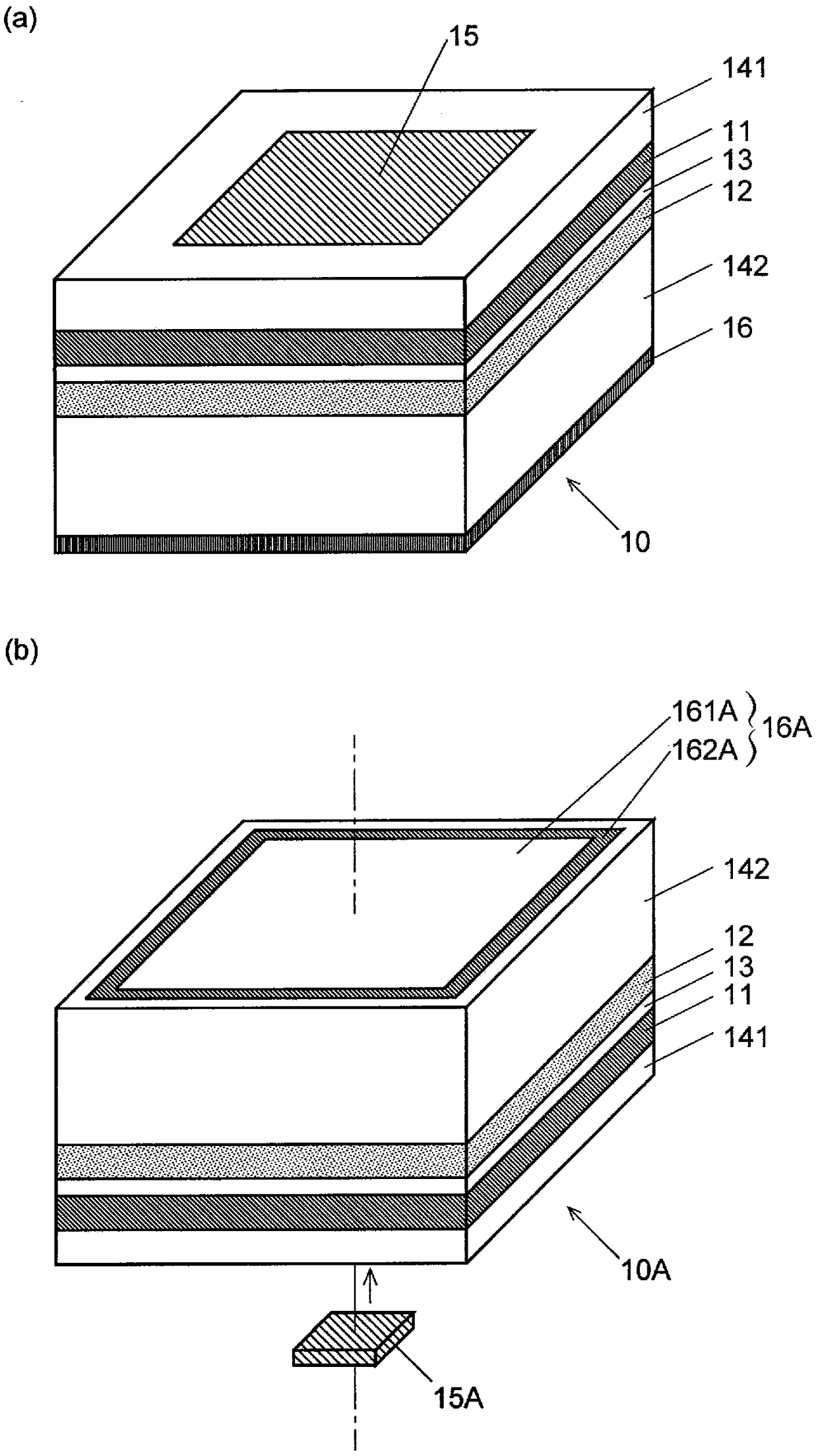

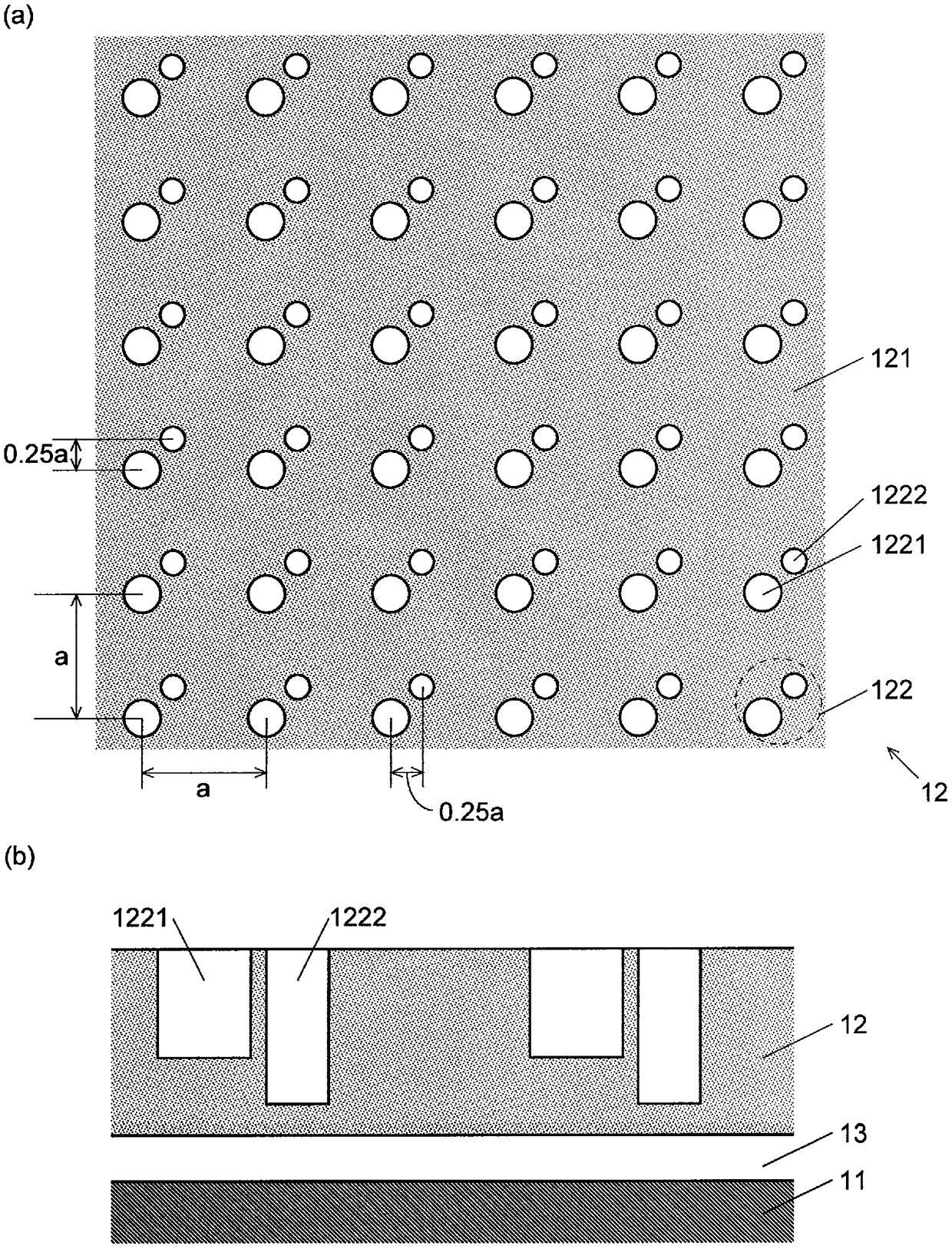

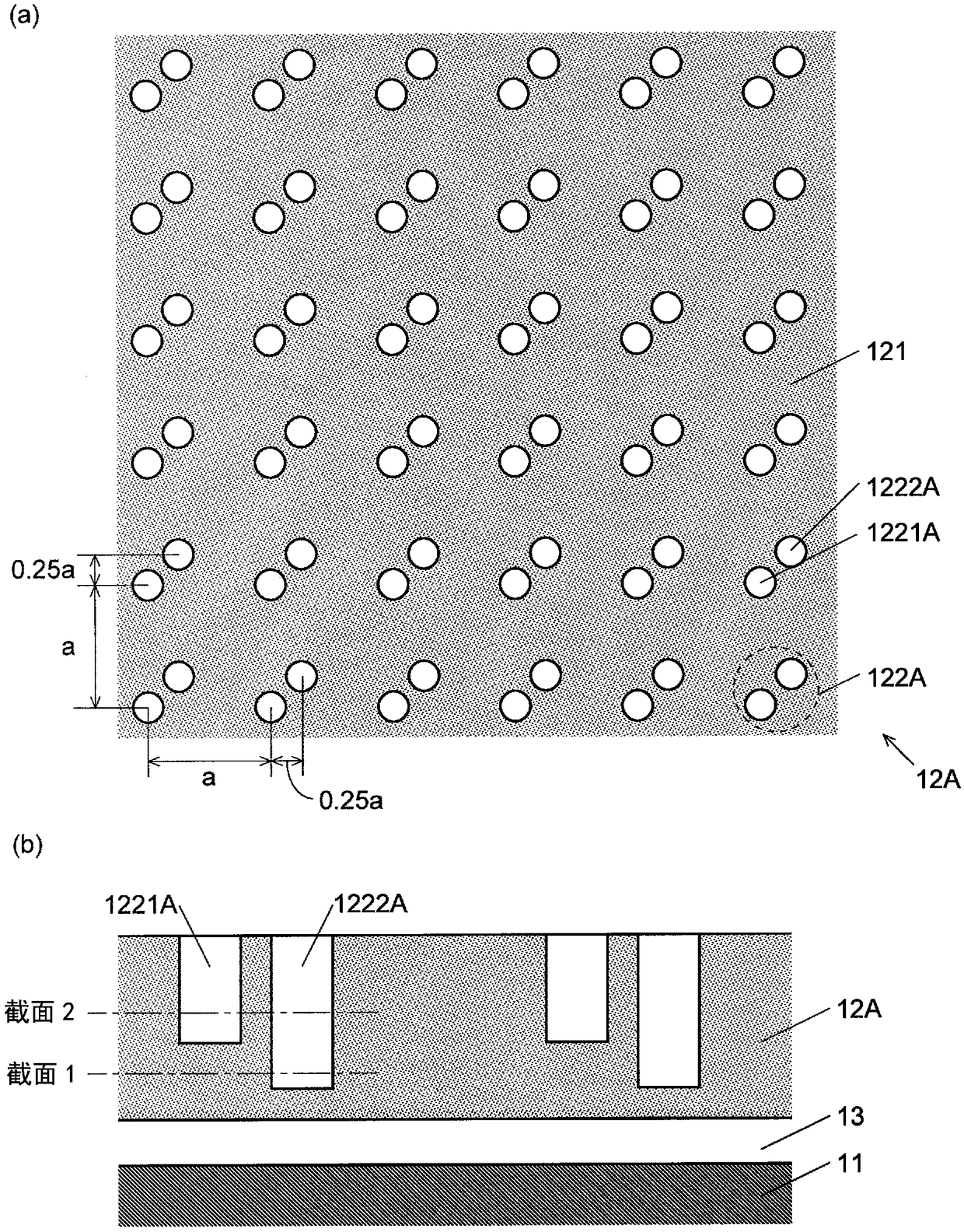

[0060] use Figure 1 to Figure 19 Embodiments of the two-dimensional photonic crystal surface emitting laser according to the present invention will be described.

[0061] (1) Structure of the two-dimensional photonic crystal surface emitting laser of the present embodiment

[0062] The two-dimensional photonic crystal surface emitting laser 10 of the present embodiment is as figure 1 As shown in (a), it has the order of the first electrode 15, the first cladding layer 141, the active layer 11, the spacer layer 13, the two-dimensional photonic crystal layer 12, the second cladding layer 142, and the second electrode 16. A structure that stacks them. Wherein, the order of the active layer 11 and the two-dimensional photonic crystal layer 12 can be reversed to the above. exist figure 1 In (a), for convenience, the first electrode 15 is shown as the upper side, and the second electrode 16 is shown as the lower side, but the orientation of the two-dimensional photonic crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com