Methods and compositions for readily removing nail coatings

A nail, coating technology, applied in the direction of manicure, manicure or pedicure tools, application, etc., can solve problems such as difficulty in removing the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

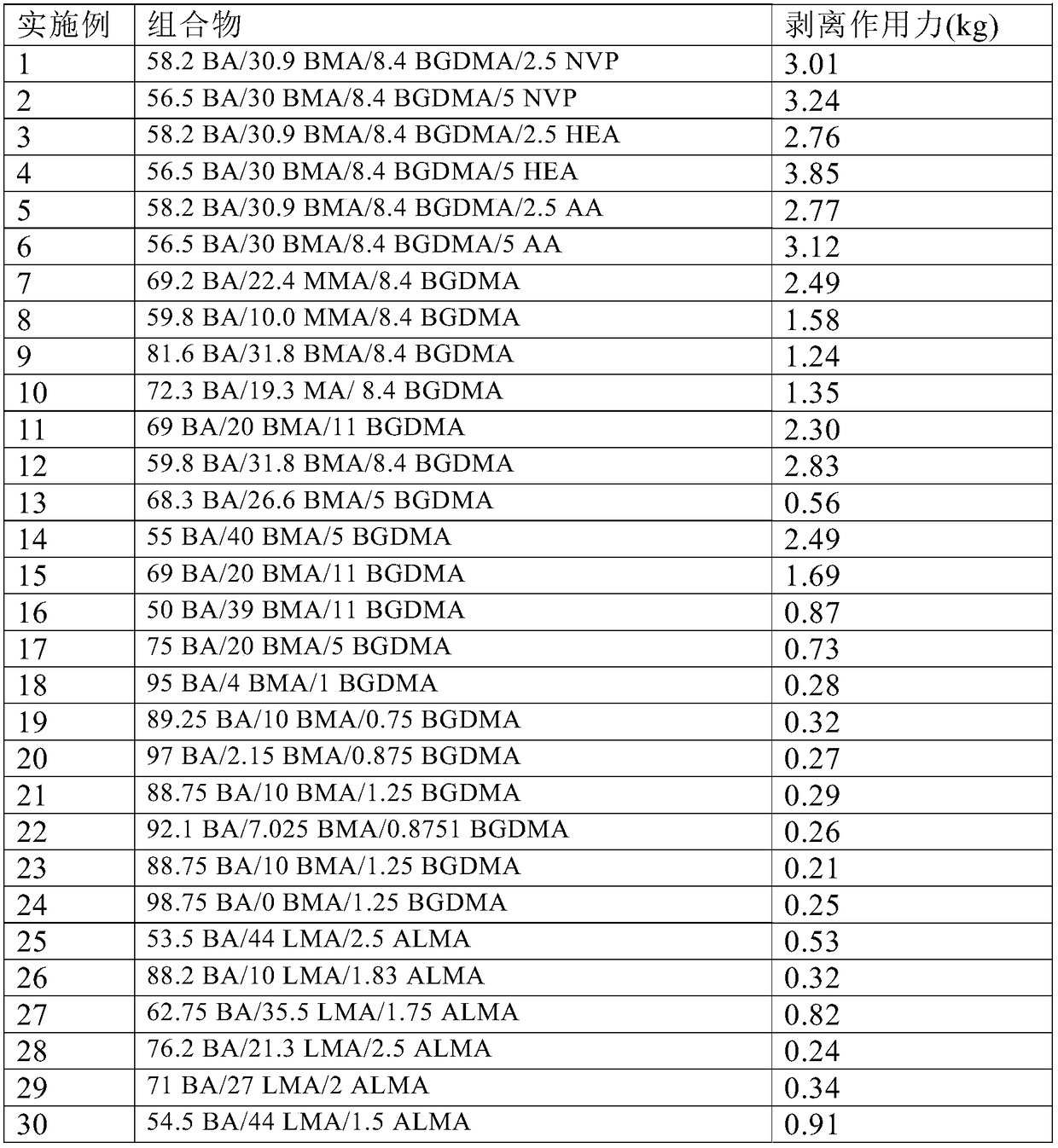

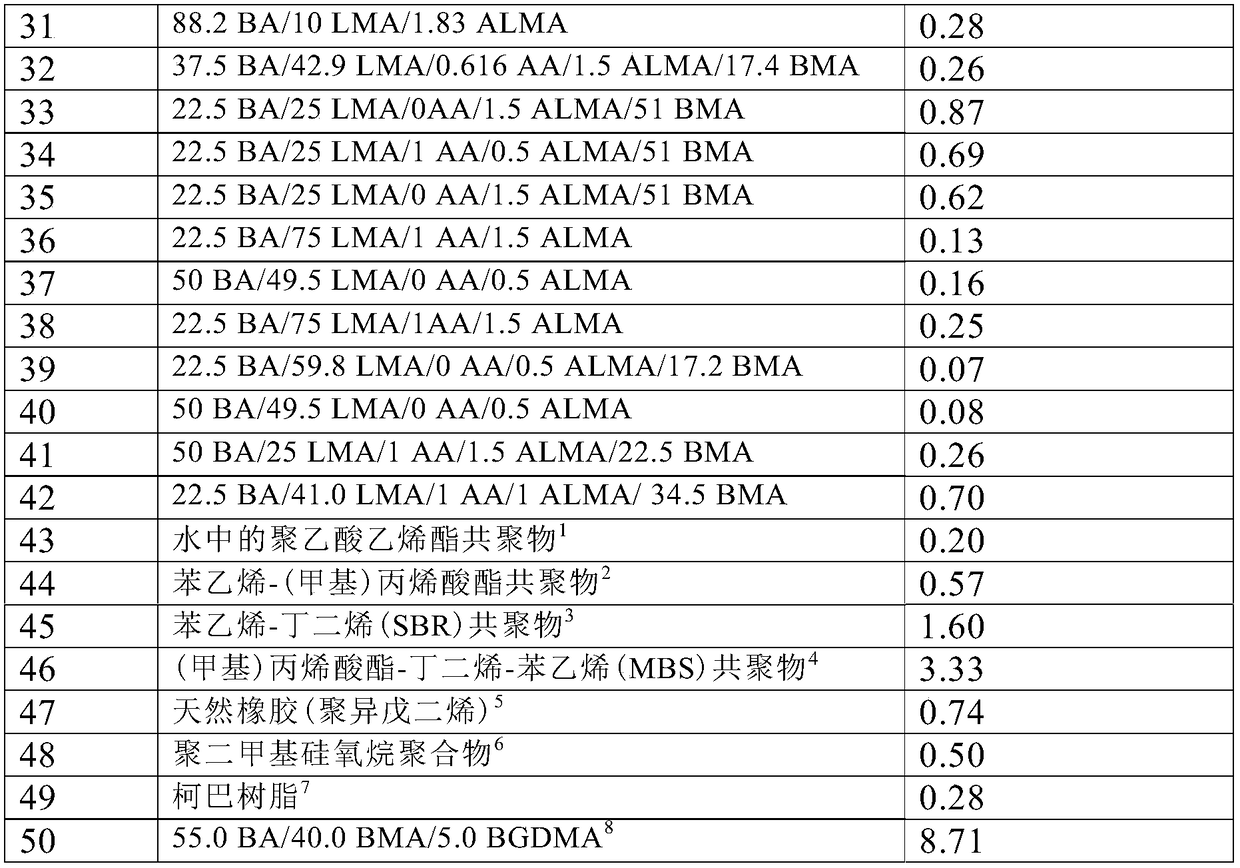

Examples

Embodiment

[0026] Synthesis of Adhesives

[0027] The following procedure describes the preparation of a representative crosslinked (meth)acrylate adhesive (butyl acrylate / butyl methacrylate / 1,3-butylene glycol dimethacrylate).

[0028] To a 500 mL resin flask equipped with a condenser, nitrogen inlet, mechanical stirrer with Teflon half-moon blades and heating mantle was added 170.7 g of methyl ethyl ketone. The apparatus was placed under a gentle flow of nitrogen, water was started to pass through the condenser, and agitation was started at 225 rpm. The solvent was then heated to and held at 78 to 79°C. Add 55.0 g of butyl acrylate, 40.0 g of butyl methacrylate, 5.0 g of 1,3-butylene glycol dimethacrylate, 1.0 g of VAZO 52 (2,2'- Nitrogen bis(2,4-dimethylvaleronitrile) and 10.0 g of methyl ethyl ketone solution. During the addition process, the temperature of the reaction solution was allowed to rise to 80-82 ° C. After the addition was completed, the reaction solution was kept at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com