Leveling mechanism of wafer bracket, wafer lifting mechanism and reaction chamber

A technology of wafer bracket and leveling mechanism, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as complicated process, small adjustable range, and limited adjustment amount, so as to simplify the leveling process and improve Process efficiency, the effect of increasing the adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order for those skilled in the art to better understand the technical solution of the present invention, the leveling mechanism of the wafer carrier, the wafer lifting mechanism and the reaction chamber provided by the present invention will be described in detail below with reference to the accompanying drawings.

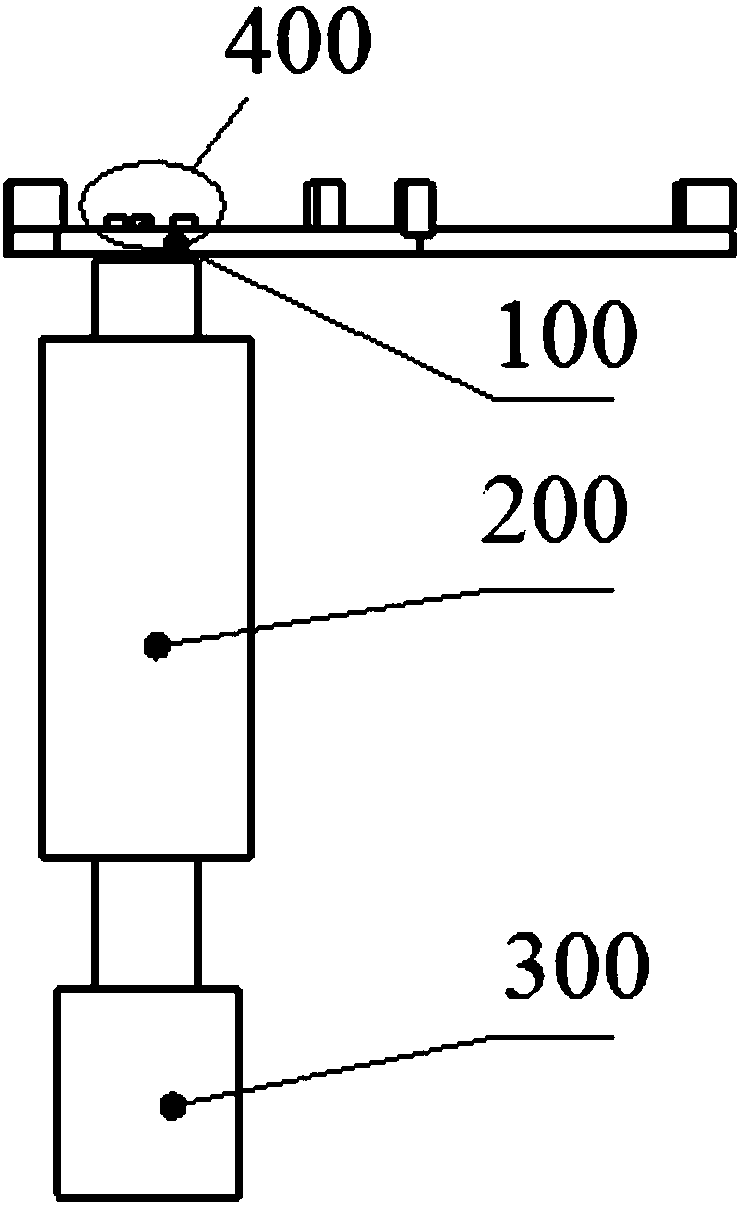

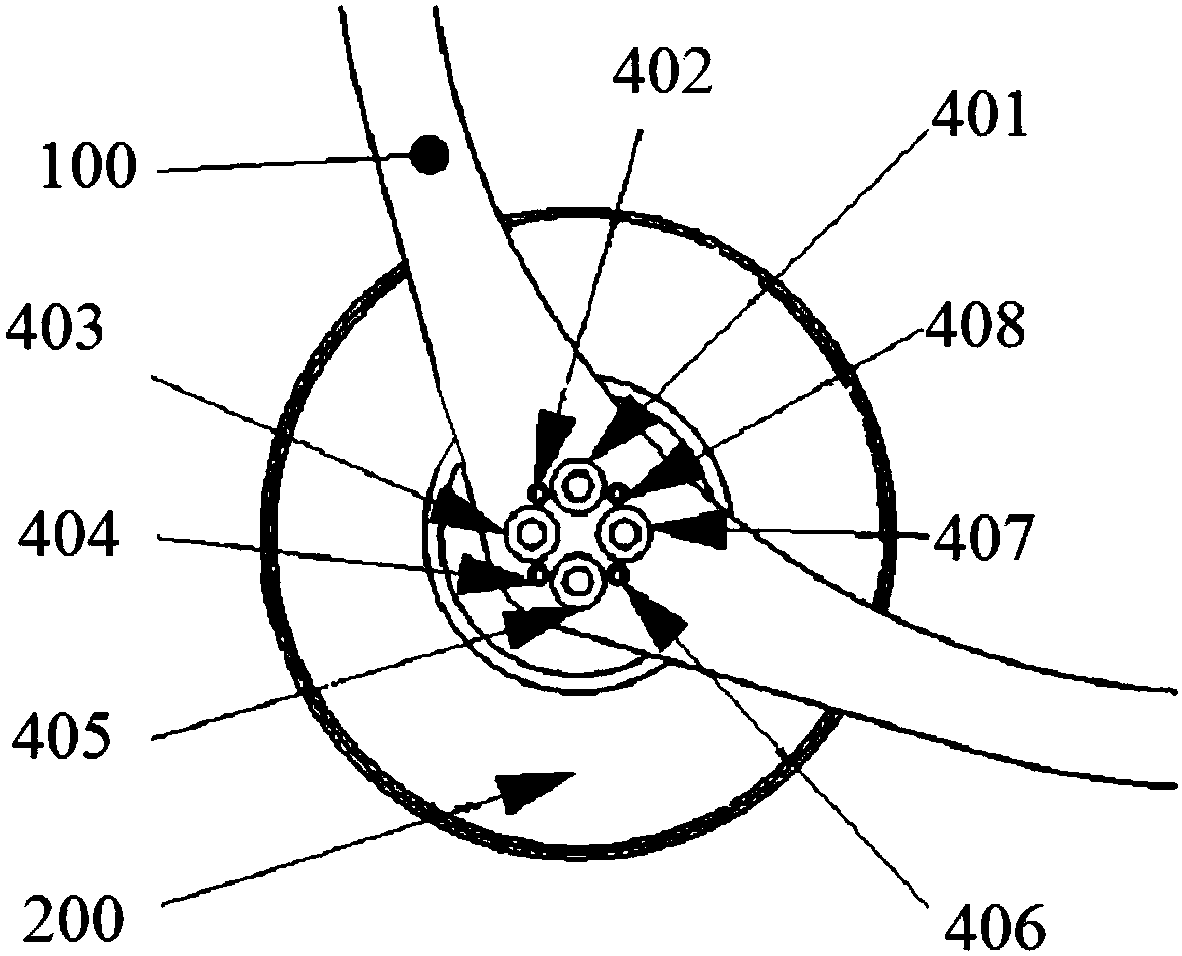

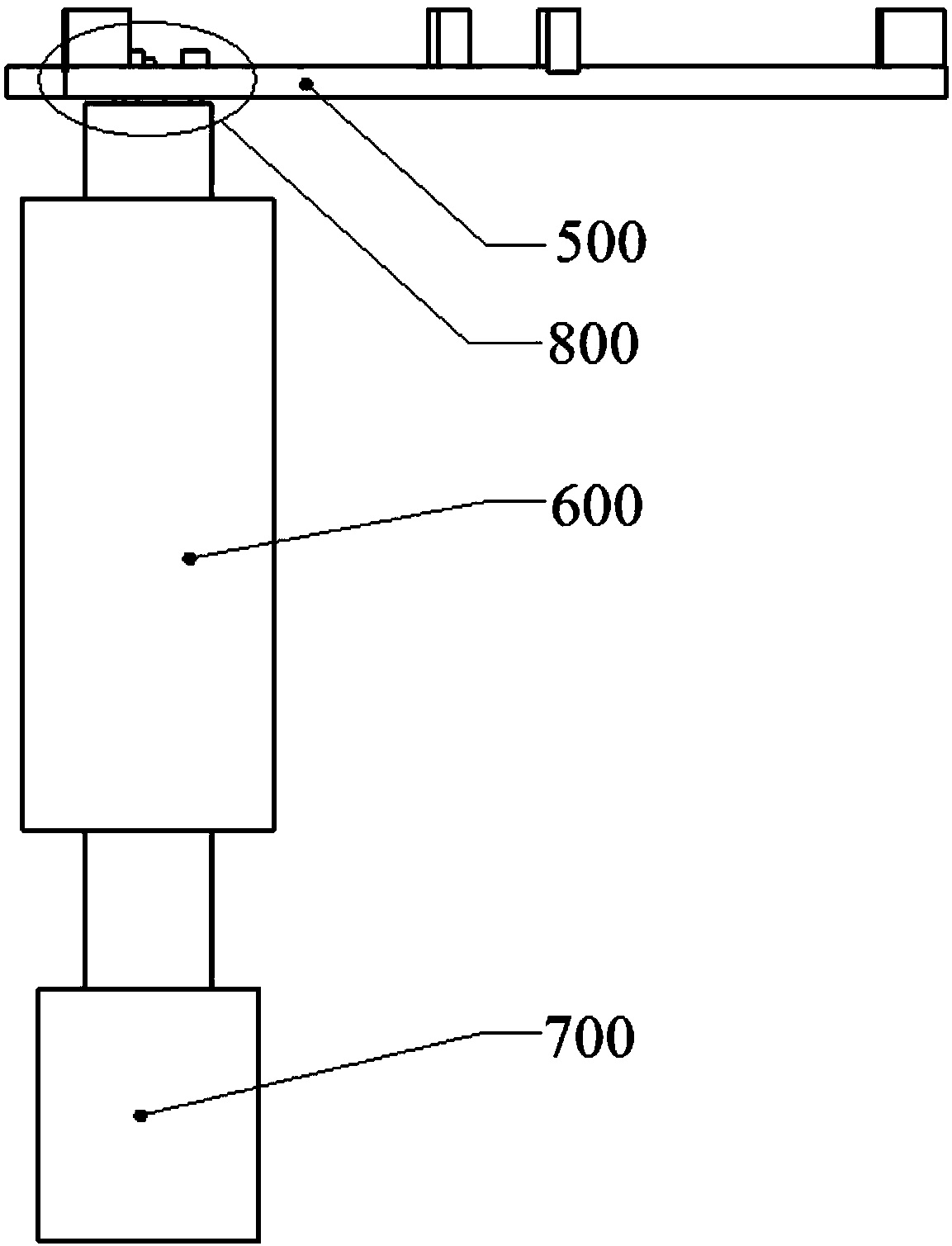

[0028] Please also refer to Figure 3 ~ Figure 6 , the wafer lifting mechanism provided by the embodiment of the present invention includes a wafer carrier 500 , a lifting shaft 600 and a driving source 700 . Wherein, the lifting shaft 600 is arranged vertically, and the lower end of the lifting shaft 600 is connected with the driving source 700 , and the upper end of the lifting shaft 600 is connected with the wafer carrier 500 through the leveling mechanism 800 . Driven by the driving source 700, the lifting shaft 600 drives the wafer carrier 500 to move up and down, so as to cooperate with the manipulator to complete the wafer pickup or placement. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com