Stage lamp imaging cutting disc upper module

A technology for cutting discs and stage lights, used in outdoor lighting, lighting applications, lighting and heating equipment, etc., can solve the problems of unstable movement of cutting discs and unclear beam imaging, and achieve the effect of improving clarity and reducing vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

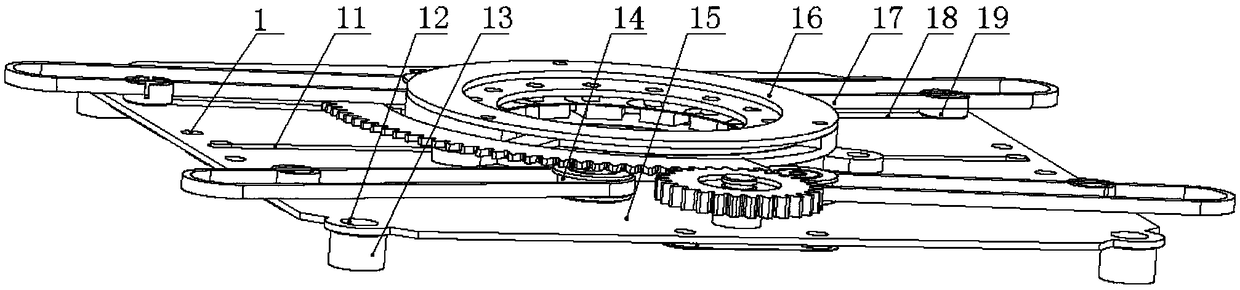

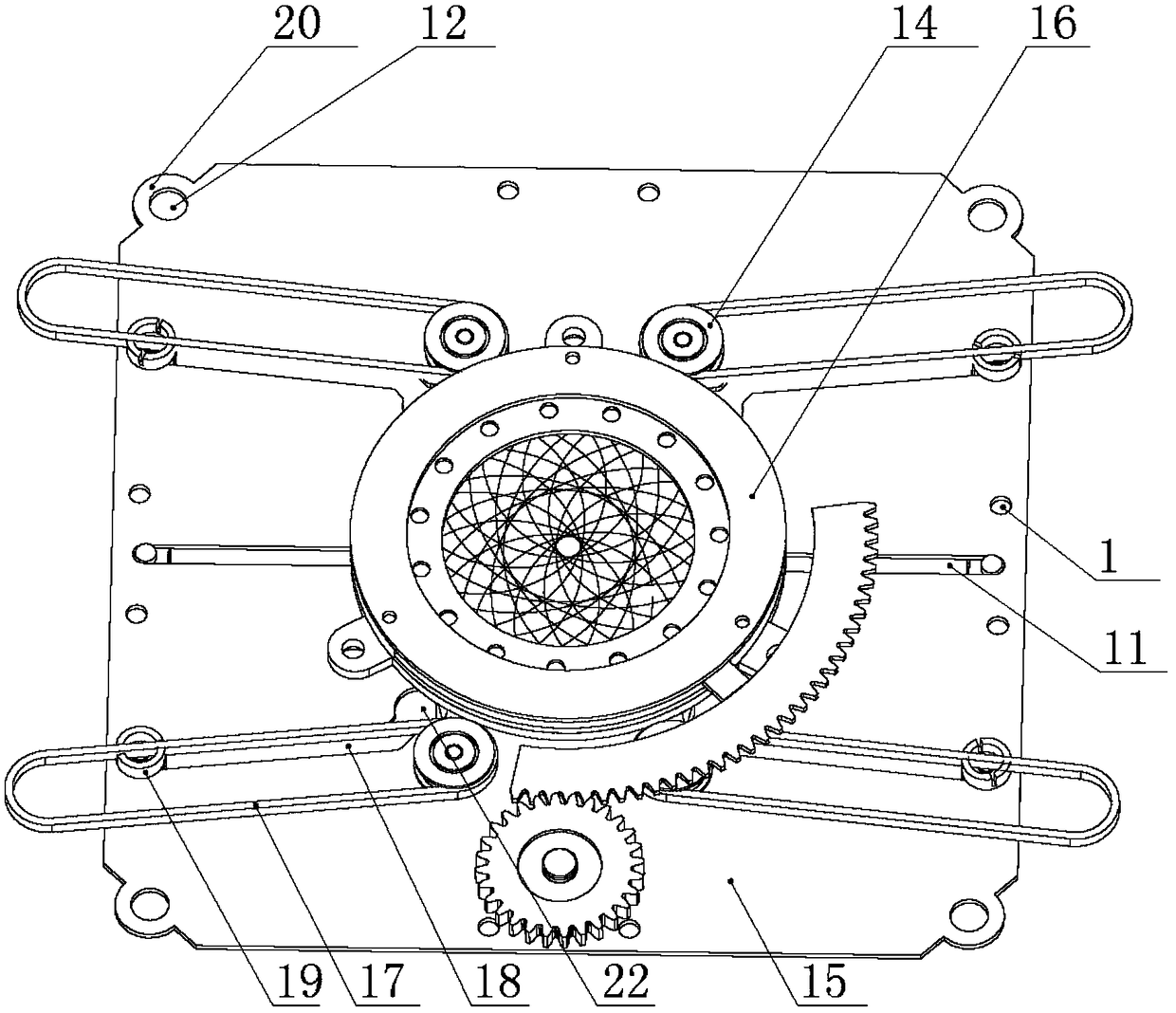

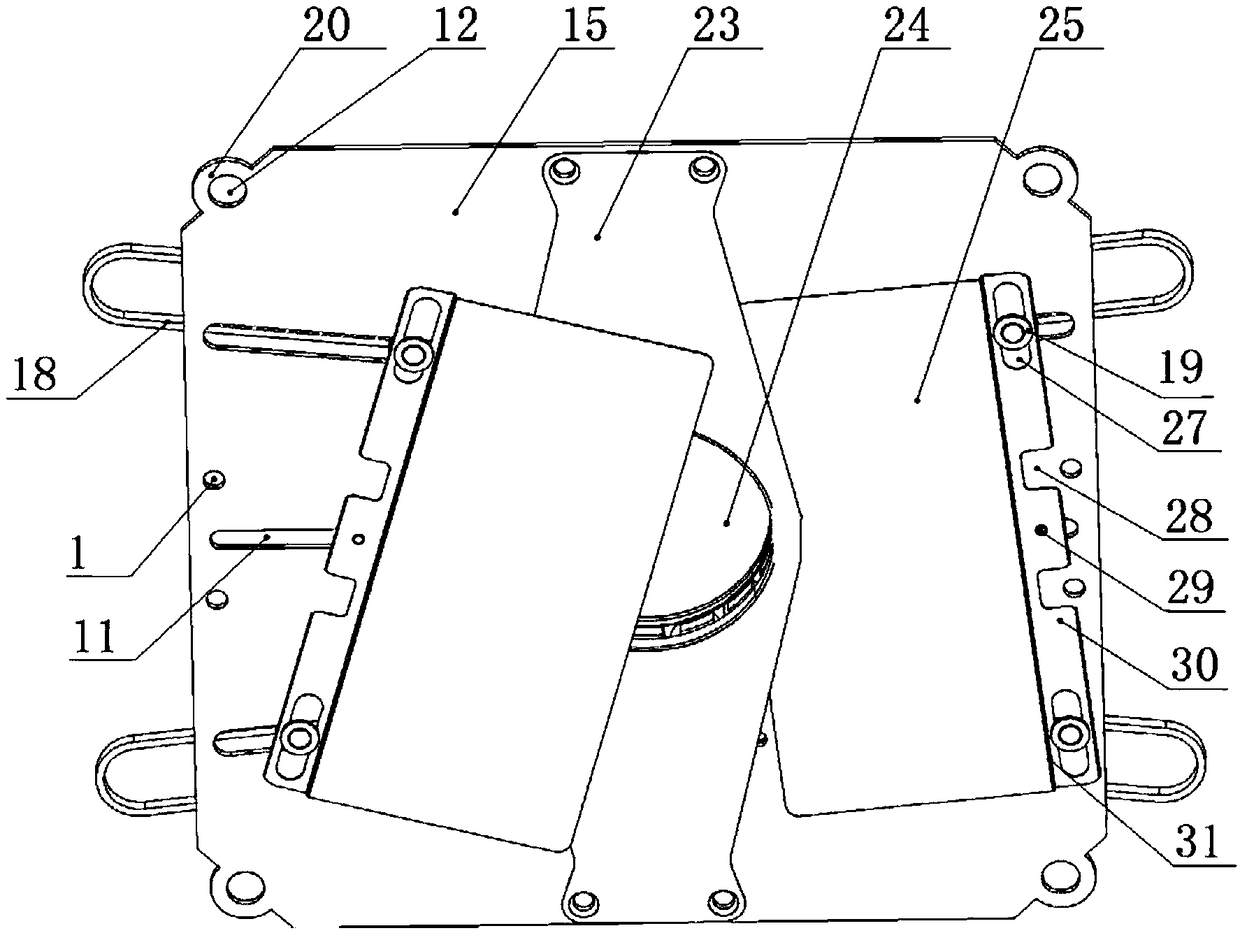

[0023] The reference signs in the drawings of the description include: socket 1, guide groove 11, connecting hole 12, heightening column 13, runner 14, plate body 15, aperture 16, timing belt 17, chute 18, connector 19, Fillet 20, assembly groove 22, partition 23, beam hole 24, cutting blade body 25, transverse groove 27, groove 28, guide column 29, transverse bending body 30, vertical bending body 31.

[0024] Such as figure 1 As shown, a stage light imaging cutting disc upper module of the present invention includes a rectangular plate body 15, the four corners of the plate body 15 are provided with connecting holes 12, and the bottom of the four corners of the plate body 15 are welded with hollow heightening columns 13. The tall column 13 communicates with the connecting hole 12 . combine figure 2 and image 3 It can be seen that a beam hole 24 is opened in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com