Novel brake disc

A brake disc, a new type of technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the problems of affecting the braking effect, increasing the temperature of the friction plate, poor thermal conductivity, etc., to avoid ABS work failure, ensure Braking effect, the effect of avoiding brake jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

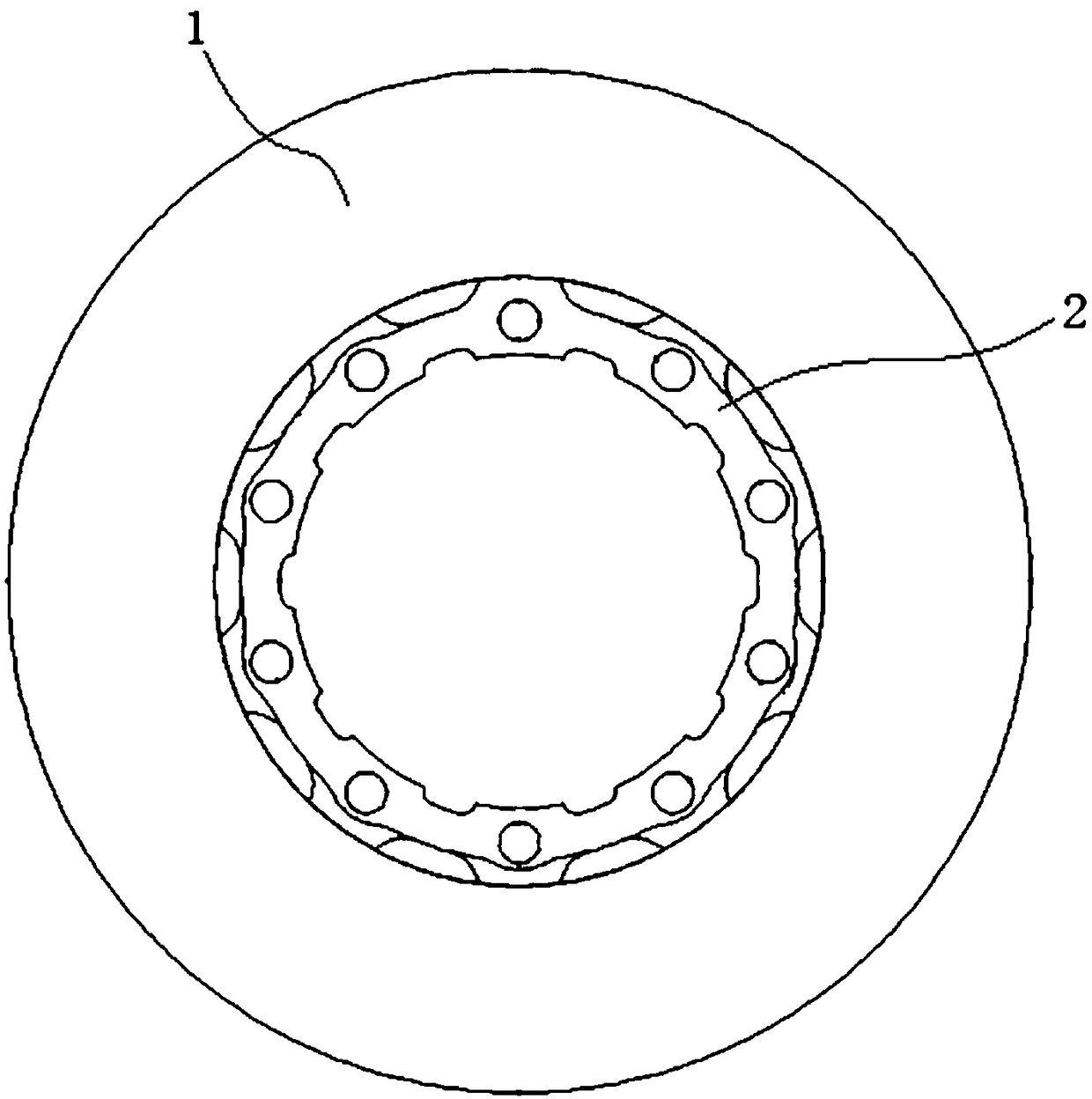

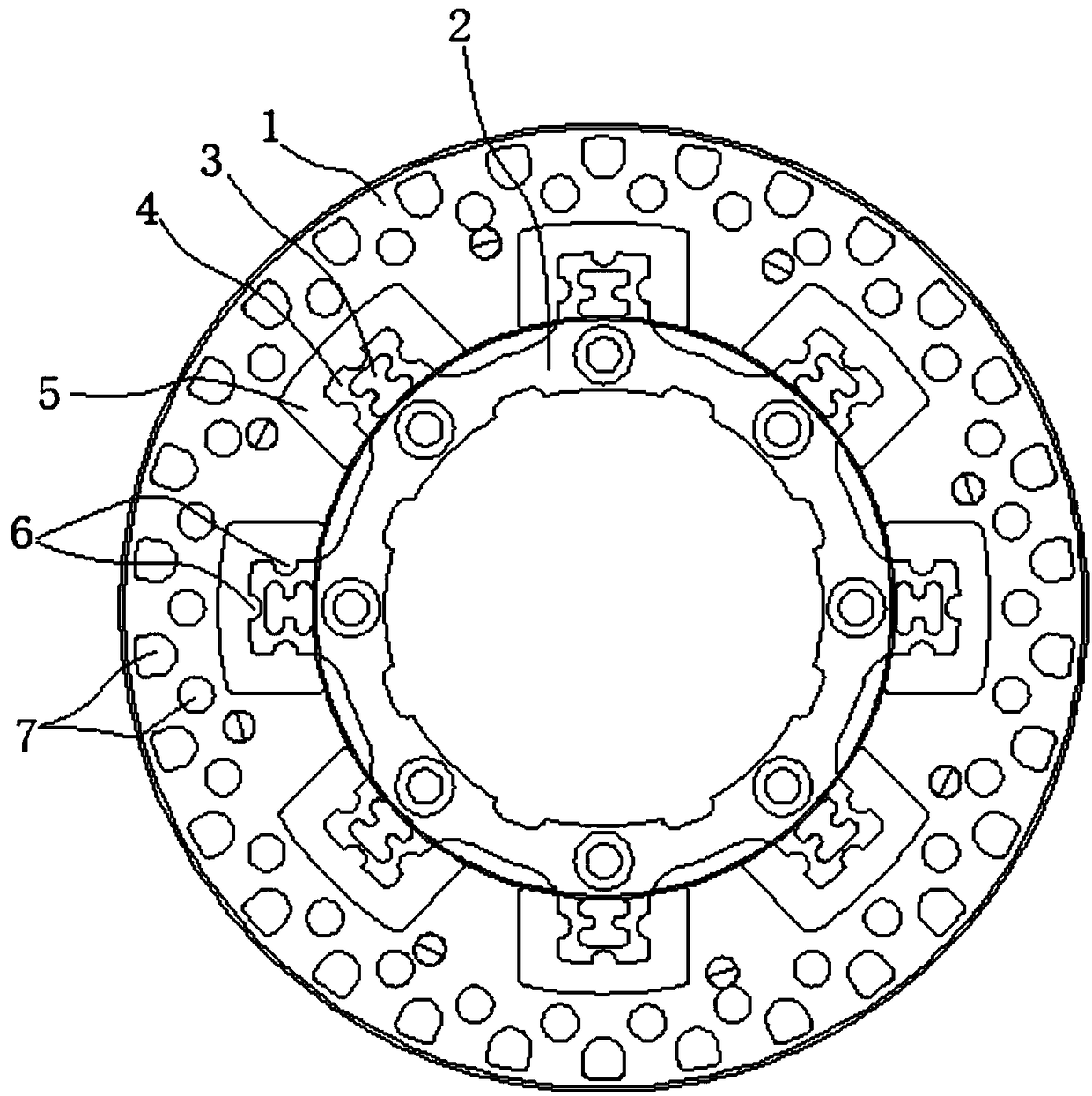

[0037] Such as figure 1 As shown, a new brake disc includes a brake friction part 1 made of gray cast iron and a hub connection part 2 made of nodular cast iron. Both the brake friction part 1 and the hub connection part 2 are ring-shaped, and the brake friction part 1 It is socketed and fixed on the outer peripheral side wall of the hub connection, and the brake friction part 1 and the hub connection part 2 are fixedly connected by solid-liquid fusion.

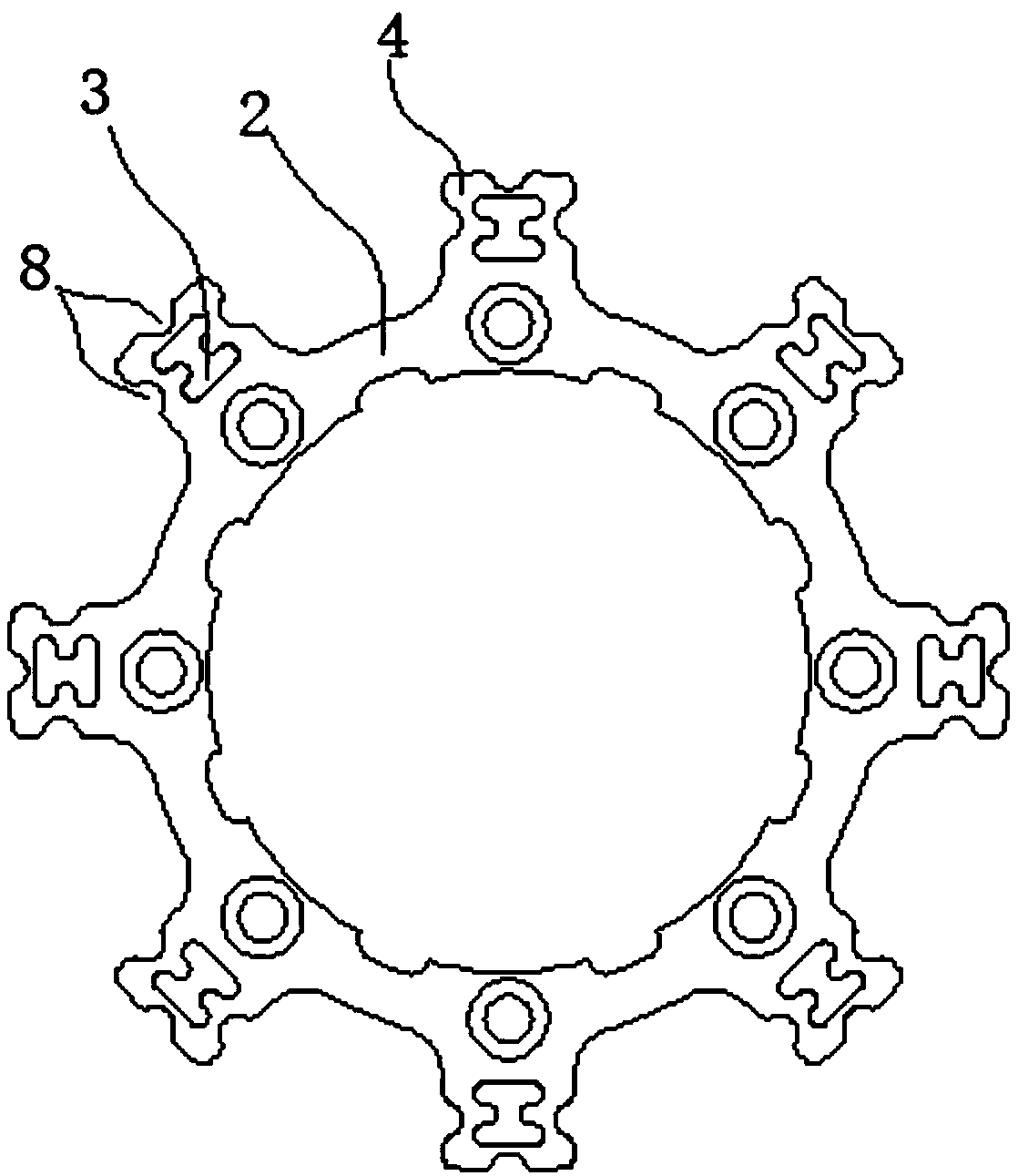

[0038] Preferably, as figure 2 As shown, there are a plurality of positioning protrusions 4 on the outer peripheral side wall of the hub connecting part 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com