Starting method of non-starting steam after tripping of power generating set of thermal power plant

A generator set, non-starting technology, applied to the starting of the engine, engine components, machines/engines, etc., can solve the problems of reducing power generation, wasting fuel, losing the starting steam source, etc., to ensure safe start, safe and stable stop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

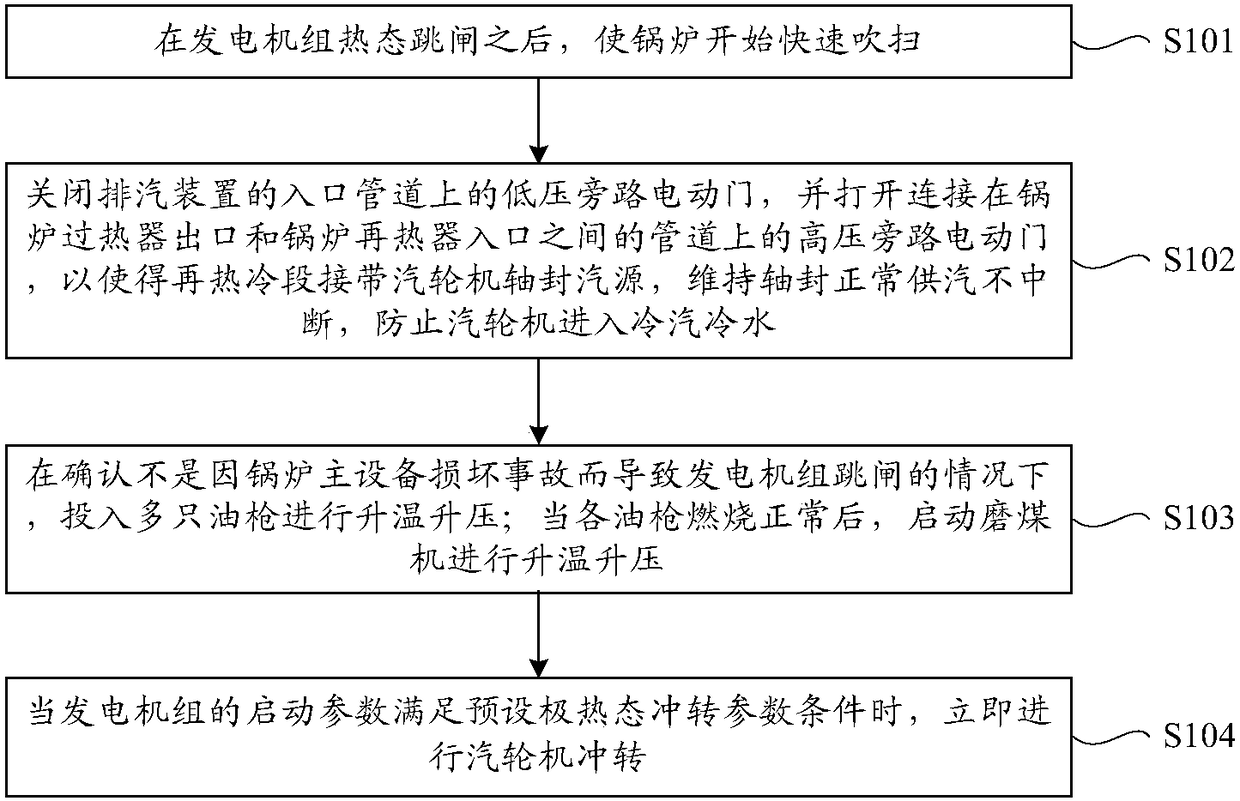

[0033] The embodiment of the present invention provides a safe start-up method without start-up steam after a trip of a thermal power plant generator set. The start-up method does not need to establish a start-up boiler, and does not need to be connected to the surrounding power plants by pipelines. On the basis of the original equipment of the unit Only through the addition of pipelines, the steam-free start-up of the power plant can be realized under the hot state. Of course, the embodiment of the present invention is only applicable to the restart of the generating set without starting steam after tripping, and is not applicable to the initial starting of the generating set, which still requires starting steam provided by the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com