Yarn covering machine

A covering wire machine and covering wire technology are applied in spinning machines, continuously wound spinning machines, textiles and paper making, etc., which can solve the problems of poor covering effect and low degree of mechanization, and improve product quality. , The effect of improving production quality and automatically replenishing lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

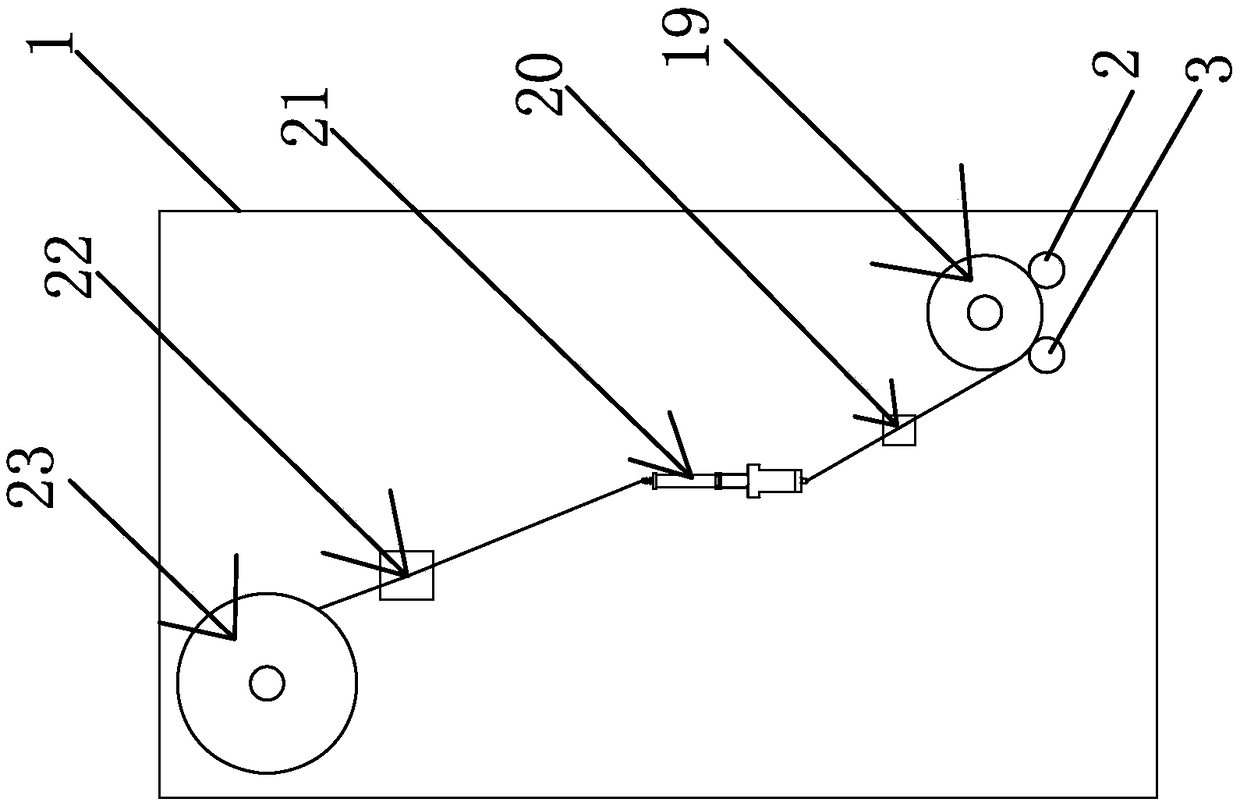

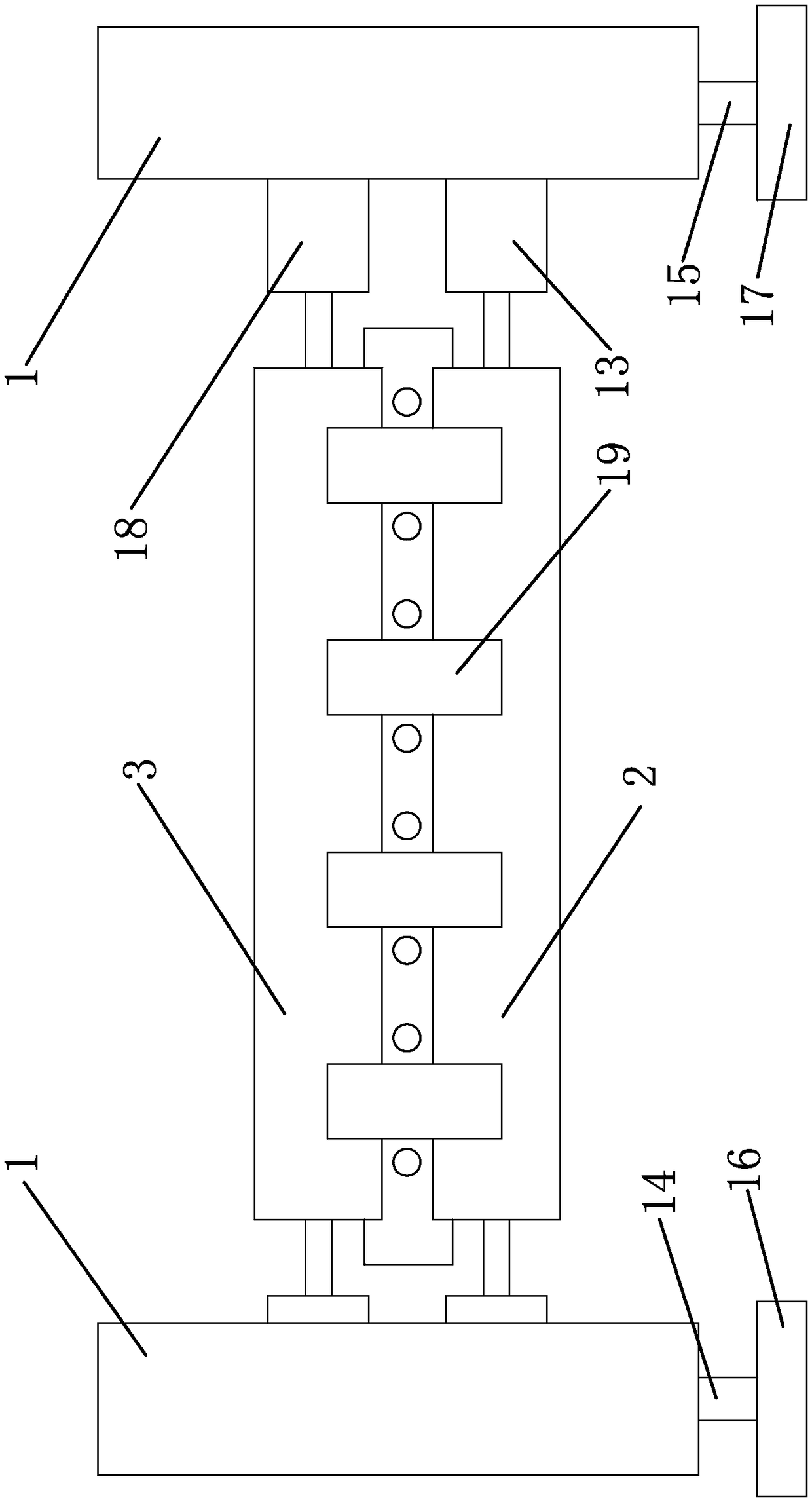

[0035] like Figure 1-8 As shown, a kind of covering silk machine comprises frame 1, and frame 1 is provided with the discharging mechanism that can discharge spandex successively from bottom to top, and the tension mechanism 20 that can regulate tension of spandex can be used for spandex and The coating mechanism 21 that polyester is coated, the oiling mechanism 22 that can oil the coated yarn, and the uniform wire take-up mechanism 23 that can collect the coated yarn.

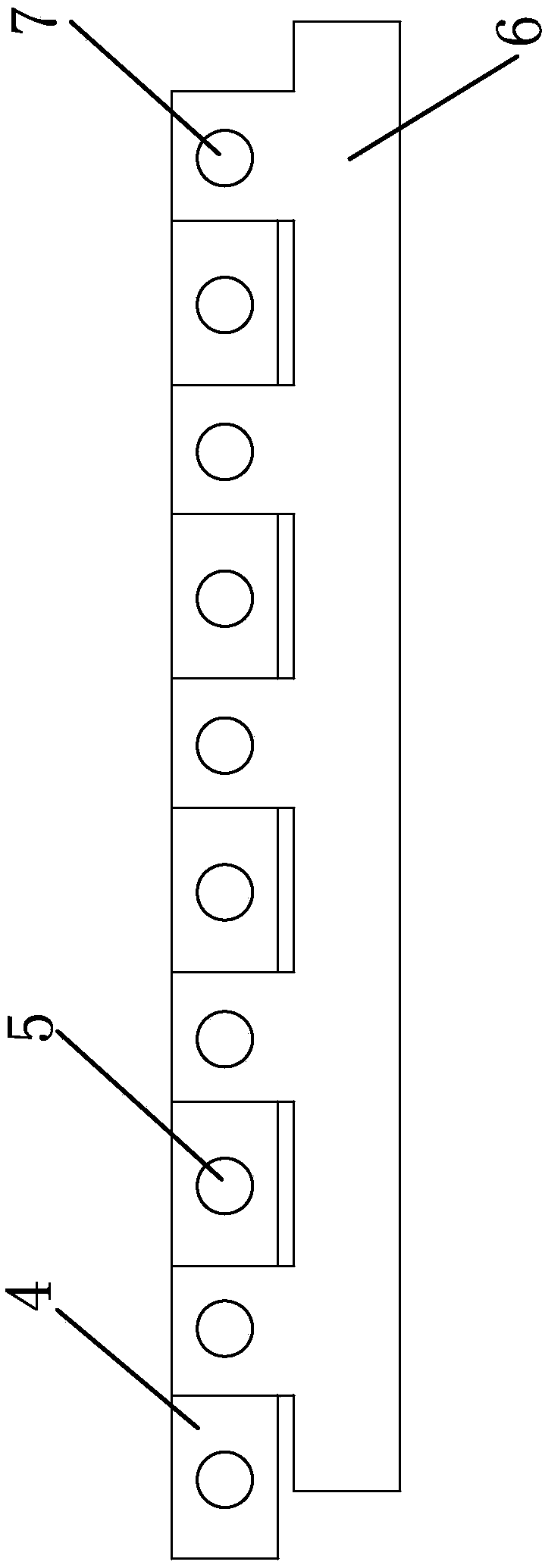

[0036] like Figure 2-4As shown, the discharge mechanism includes a rotating roller one 2 and a rotating roller two 3, the rotating roller one 2 and the rotating roller two 3 are arranged in parallel on the frame 1, and the frame 1 is provided with a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com