Varnish for photoalignment film and liquid crystal display device

A technology of photo-alignment film and varnish, applied in optics, nonlinear optics, coatings, etc., can solve the problems of reliability decline of liquid crystal display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1、2

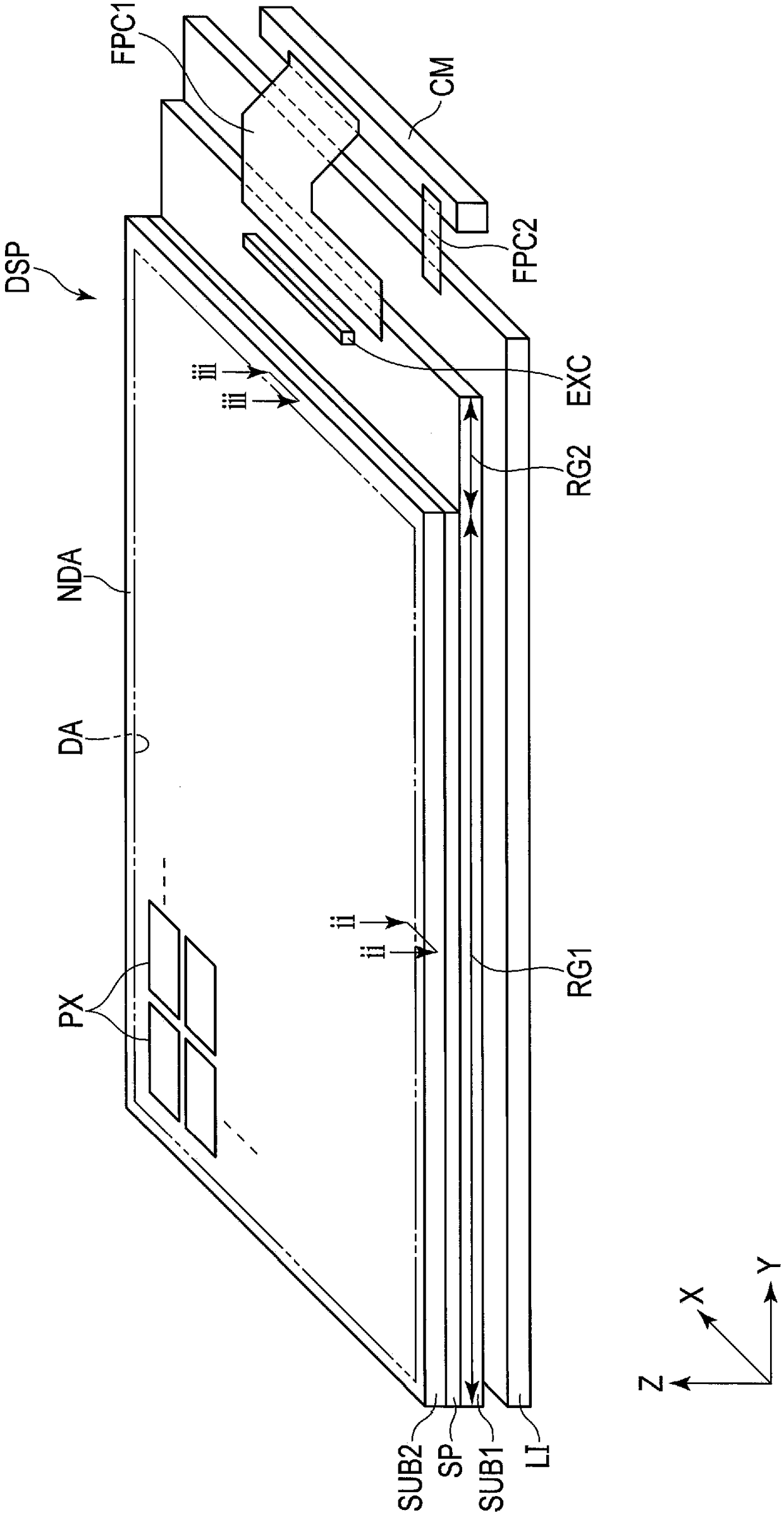

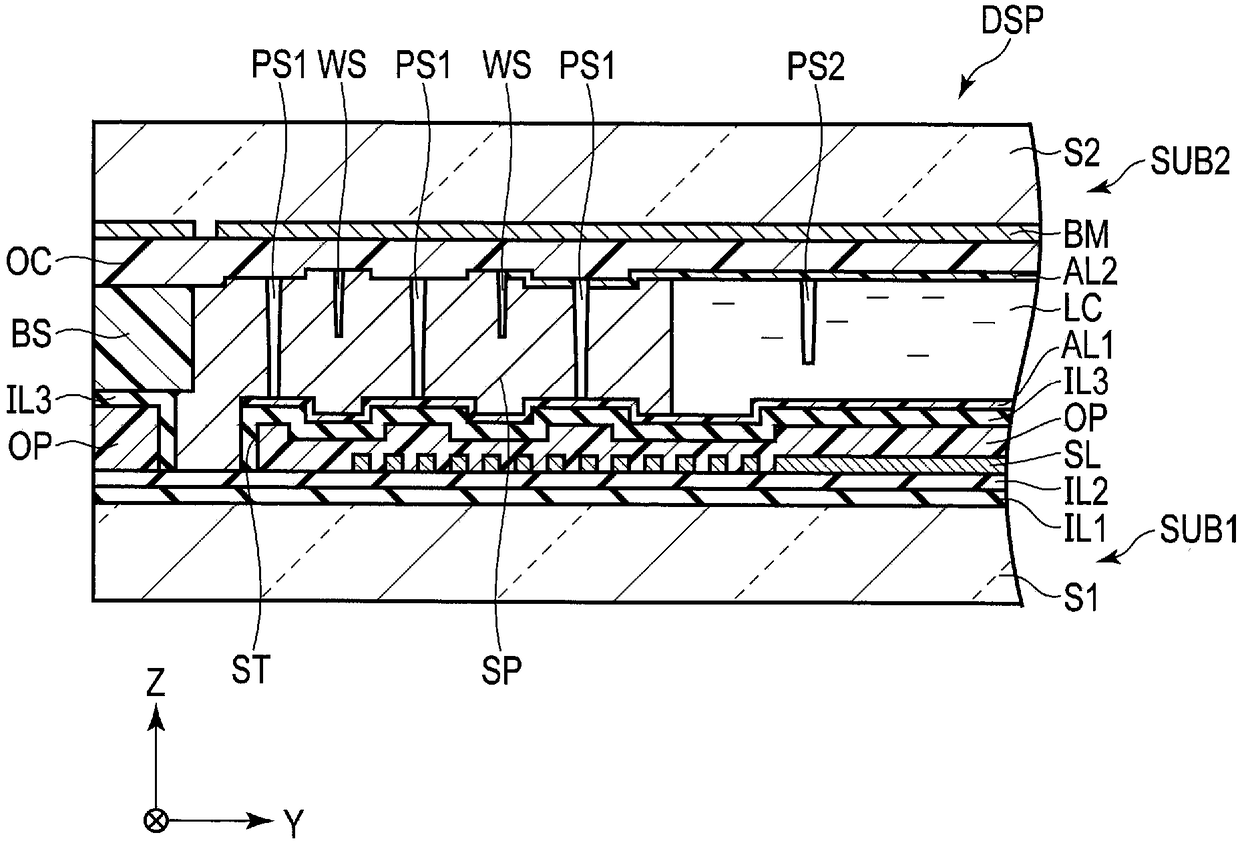

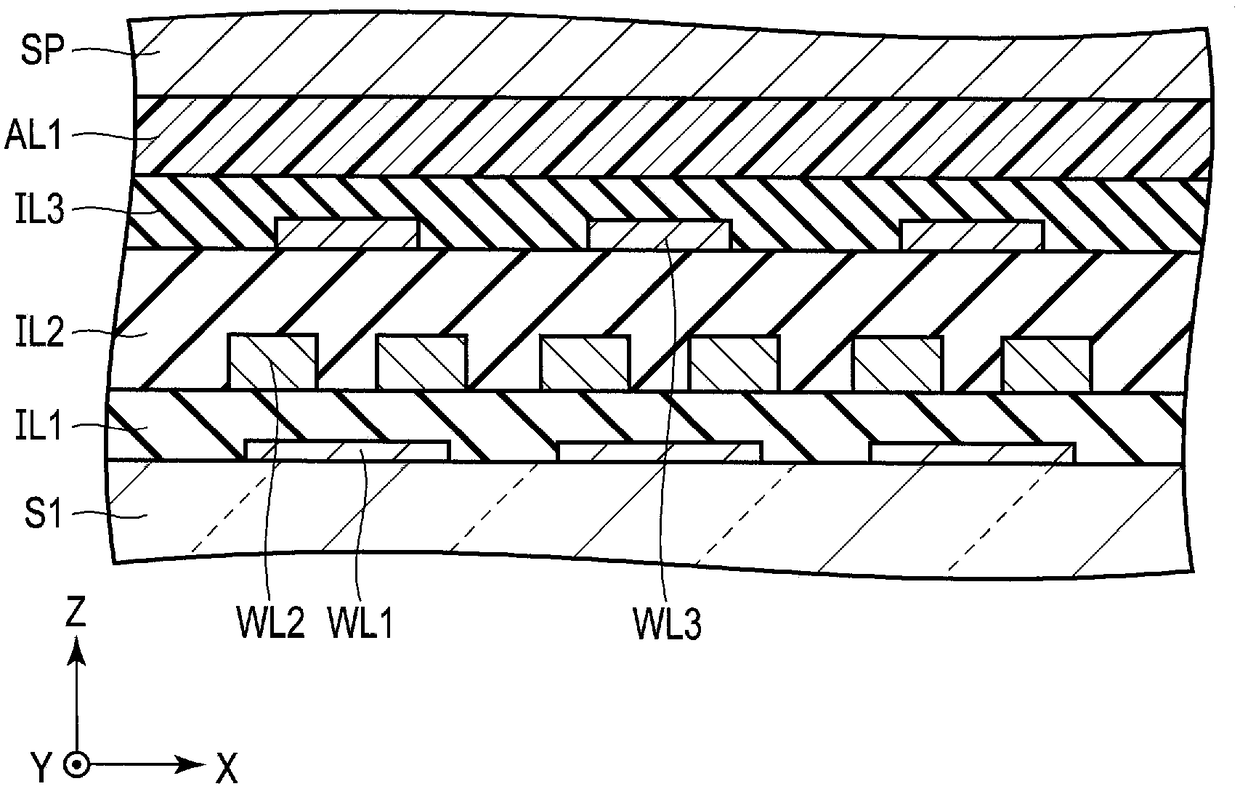

[0156] To the polyamic acid-based compounds in Table 1 above, alkoxysilanes as shown in Table 2 below were added (may not be added) and stirred until uniform to prepare respective coating liquids. exist figure 1 and figure 2 In the liquid crystal display device having the structure shown, each coating liquid is applied on the area where the first alignment film AL1 should be applied on the first substrate SUB1 and the area where the second alignment film AL2 should be applied on the second substrate SUB2, and heated. Imidation is carried out at 200°C. The imidization ratios were all 80%. For each imidized film, photo-alignment treatment was performed using short-wavelength ultraviolet light. After washing each alignment film, using the first substrate SUB1 on which the first alignment film AL1 was formed and the second substrate SUB2 on which the second alignment film AL2 was formed as described above, a conventional method was used to fabricate figure 1 The liquid crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com