Method for treating sulfur-containing wastewater in gasoline refining process

A treatment method and technology for wastewater, which can be used in neutralization water/sewage treatment, natural water treatment, water/sewage treatment, etc., and can solve the problems of high operating costs, complex processes, and demanding requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

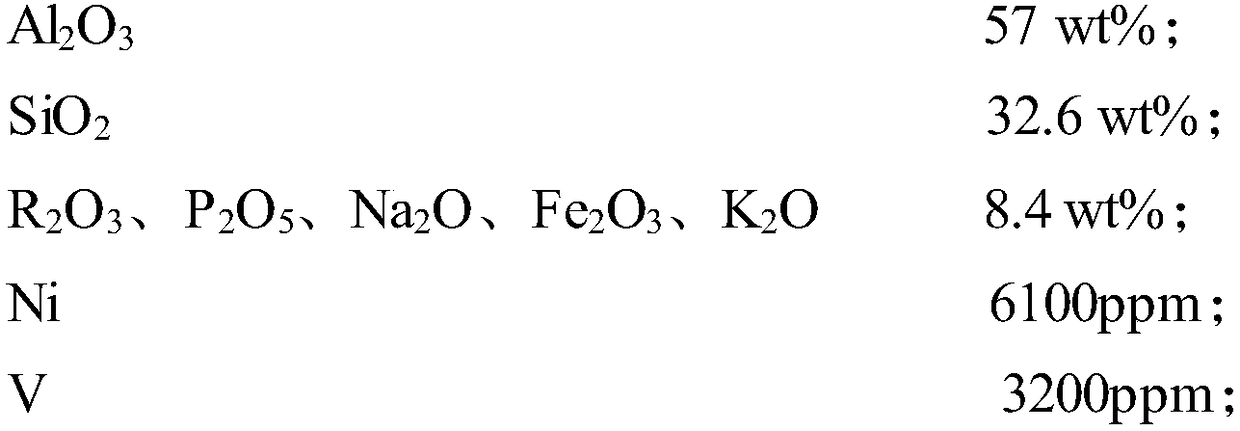

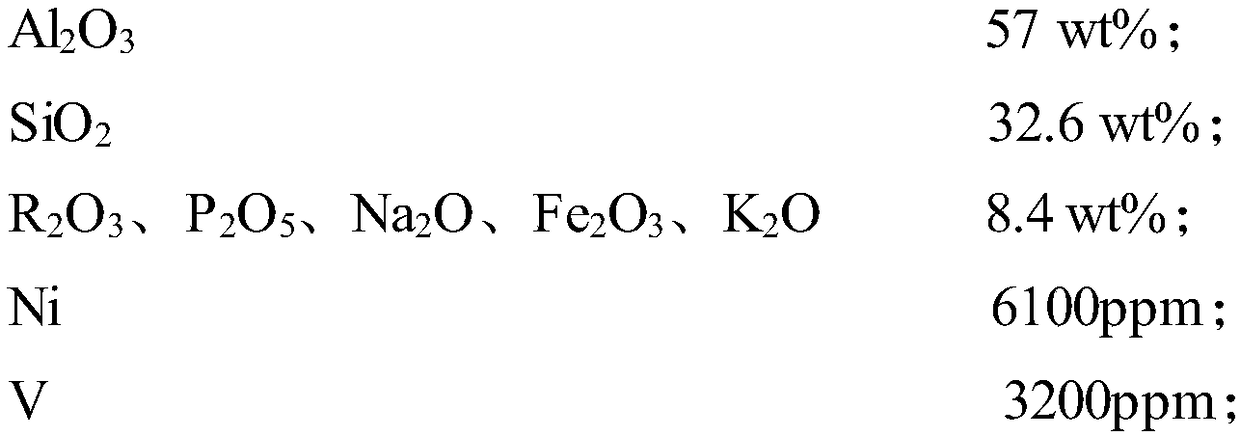

Embodiment 1

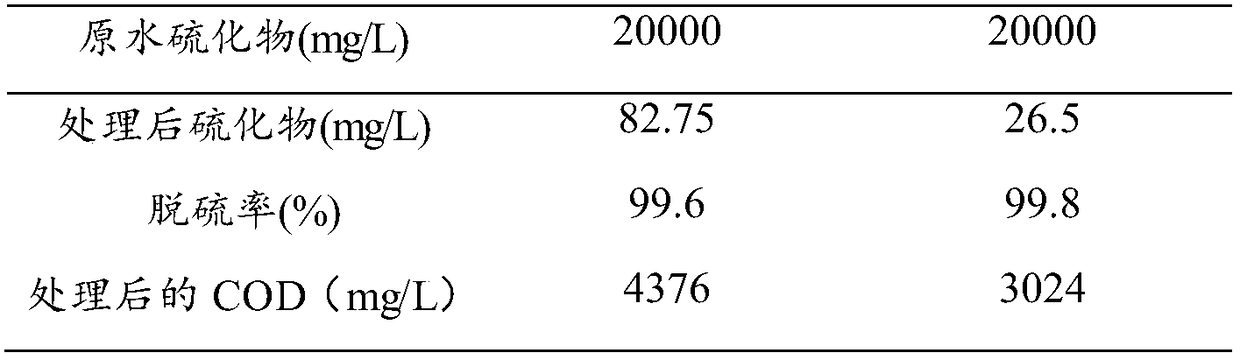

[0066] The sulfur-containing wastewater in the gasoline refining process is taken, and the pH value of the sulfur-containing wastewater is adjusted to 7 by sulfuric acid. After standing for stratification, the upper layer solution is removed, and the obtained lower layer solution is the preliminary treated wastewater.

[0067] Weigh two parts of 4g FCC balancer, bake at 400°C for 2 hours, and set aside. Add the spare two parts of FCC balancer to 100mL of sulfur-containing wastewater with different sulfide concentrations, and then add 5mL of hydrogen peroxide respectively, pass air into the obtained mixed solution, stir and mix at 65°C for 90min, and the stirring speed is 70r / min, and then stand still for 20 minutes to obtain desulfurization wastewater after solid-liquid separation.

[0068] Sampling was carried out to determine the sulfide in the water, and the removal rate of sulfide and the COD value in the treated wastewater were calculated. The results are shown in Table ...

Embodiment 2

[0072] The concentration of sulfide in sulfur-containing wastewater is 20000mg / L.

[0073] The sulfur-containing wastewater in the gasoline refining process is taken, and the pH value of the sulfur-containing wastewater is adjusted to 7 by sulfuric acid. After standing for stratification, the upper layer solution is removed, and the obtained lower layer solution is the preliminary treated wastewater.

[0074] Weigh 2g, 3g, 4g, 5g, 6g of FCC balancer respectively, after roasting at 400°C for 2h, add 100mL of the sulfur-containing waste water respectively, and then add 5mL of hydrogen peroxide respectively, and pass air into the obtained mixed solution, Stirring and mixing at 65° C. for 90 minutes at a stirring speed of 70 r / min, and then standing still for 20 minutes to obtain desulfurization wastewater after solid-liquid separation.

[0075] Sampling was carried out to determine the sulfide in the water, and the removal rate of sulfide and the COD value in the treated wastewat...

Embodiment 3

[0079] The concentration of sulfide in sulfur-containing wastewater is 20000mg / L.

[0080] The sulfur-containing wastewater in the gasoline refining process is taken, and the pH value of the sulfur-containing wastewater is adjusted to 7 by sulfuric acid. After standing for stratification, the upper layer solution is removed, and the obtained lower layer solution is the preliminary treated wastewater.

[0081] Weigh 4g of FCC balancer respectively, after roasting at 400°C for 2h, add 100mL of the sulfur-containing waste water respectively, then add 5mL, 6mL, 7mL, 8mL, 9mL of hydrogen peroxide respectively, and pass air into the obtained mixed solution, Stirring and mixing at 65° C. for 90 minutes at a stirring speed of 70 r / min, and then standing still for 20 minutes to obtain desulfurization wastewater after solid-liquid separation.

[0082] Sampling was carried out to determine the sulfide in the water, and the removal rate of sulfide and the COD value in the treated wastewat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com