Elevator door-opening machine with horizontally-arranged drive motor gap

A technology for driving motors and door openers, applied in the field of elevators, can solve the problems of large operating space, large dimensions of door openers, and low transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

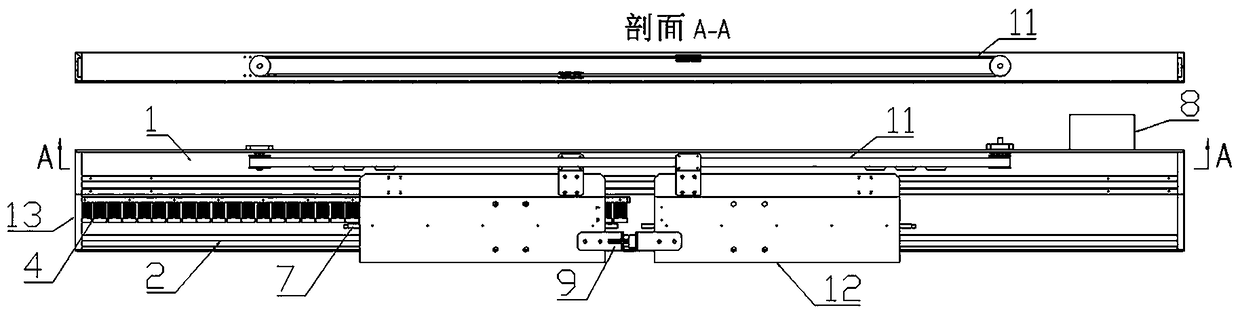

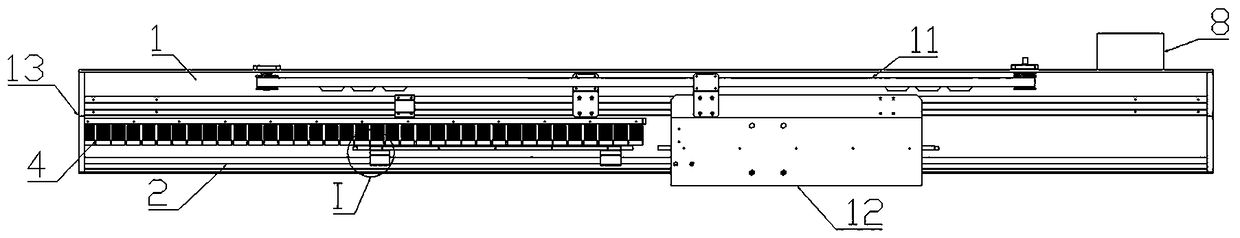

[0015] The elevator door opener with the drive motor air gap arranged horizontally according to the present invention, such as Figure 1-5 as shown,

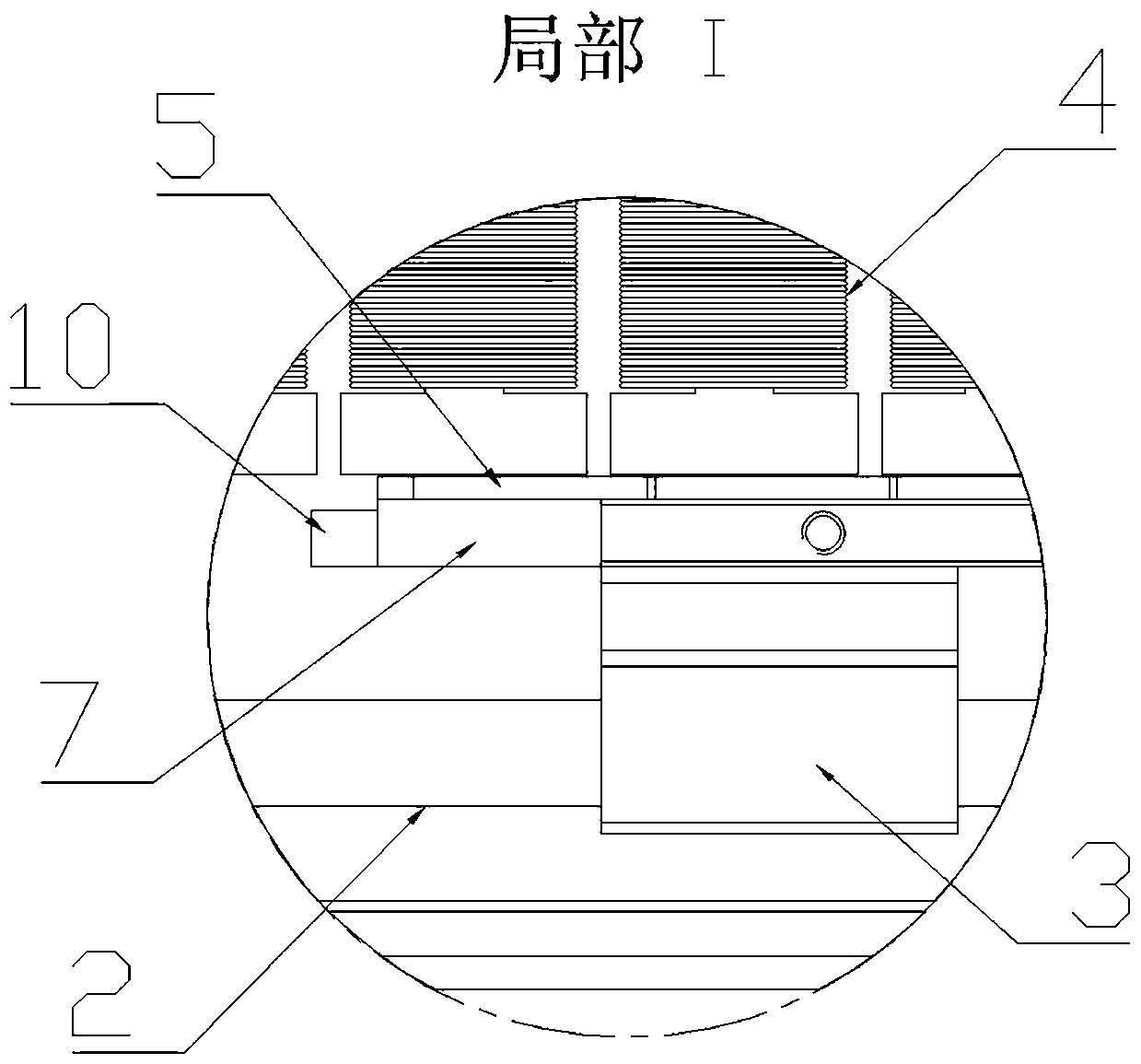

[0016] The linear bearing guide rail 2, the motor coil 4, the linkage device 11, the head, and the motor air gap 13 are all fixed on the base plate 1, as Figure 4 , 5 .

[0017] Described motor permanent magnet 5, linear bearing 3, door hanging plate 12, door opening limit 10 are all connected on the drag plate 7, as image 3 , 4 .

[0018] The door closing limit 9 is connected to the door hanging plate 12 to prevent the elevator door leaf 14 from colliding, such as figure 1 shown.

[0019] The linkage device 11 is a combination of a belt and a pulley, and two door hanging plates 12 are respectively connected on both sides of the plane formed by the axes of the two pulleys, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com