Clamping device applied to trimming arc surfaces of abrasive blocks of grinding wheel

An abrasive block and arc surface technology, which is used in abrasive surface adjustment devices, parts of grinding machine tools, grinding/polishing equipment, etc., can solve the problem of abrasive blocks flying away from the base of the grinding wheel, inconsistency in shape and size, and poor workpiece quality. and other problems, to achieve the effect of convenient and quick fixation, high consistency and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In conjunction with the accompanying drawings of the description, this invention is carefully interpreted:

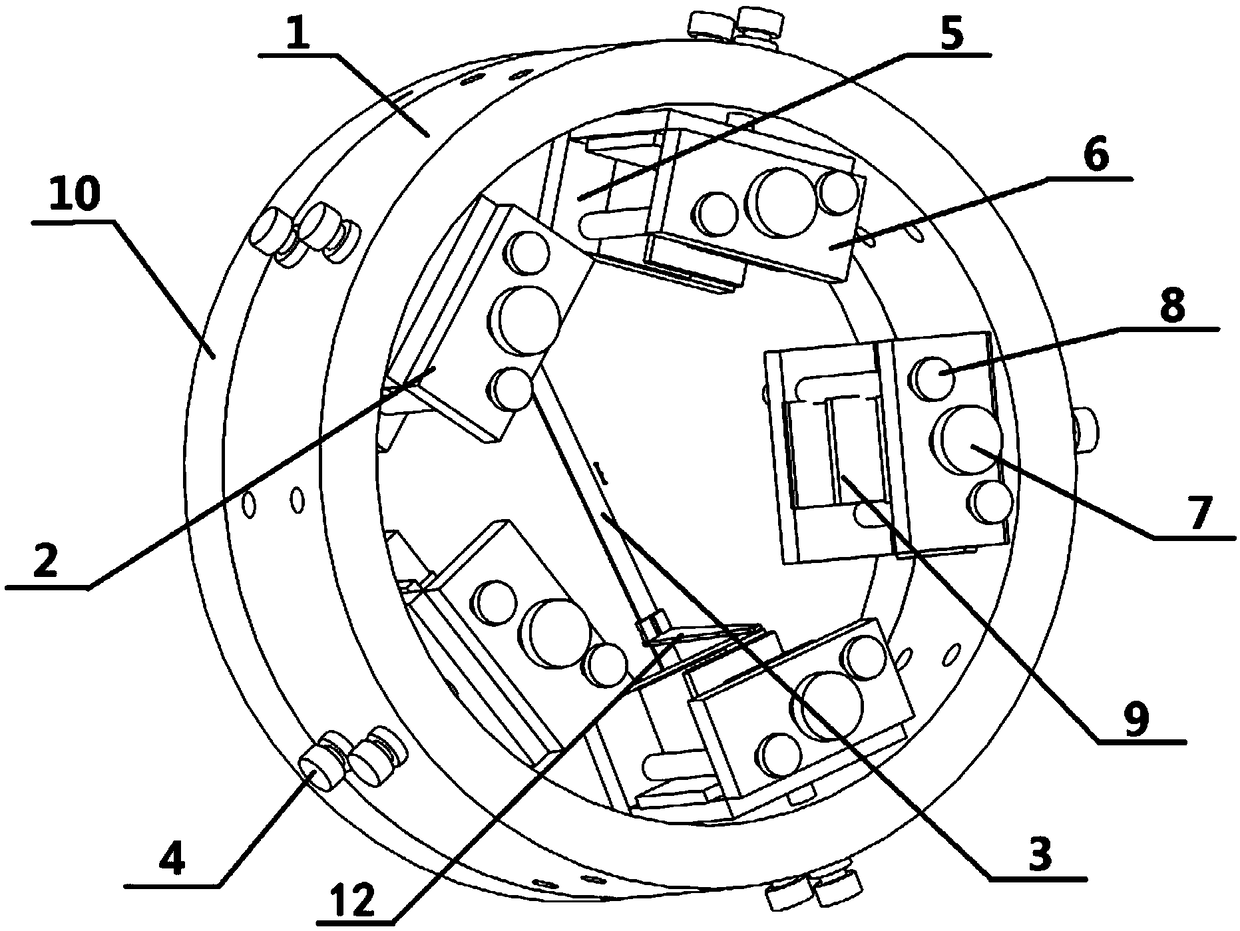

[0023] Such as figure 1 , Figure 5 As shown in (a) to (c), a clamping device applied to trim the arc surface of grinding wheel abrasive blocks, including: a circular outer casing 1, a clamp body 2 for clamping arc-shaped abrasive blocks; several clamps Concrete 2 is evenly distributed and connected on the jacket 1 with the center of the jacket 1 as the center.

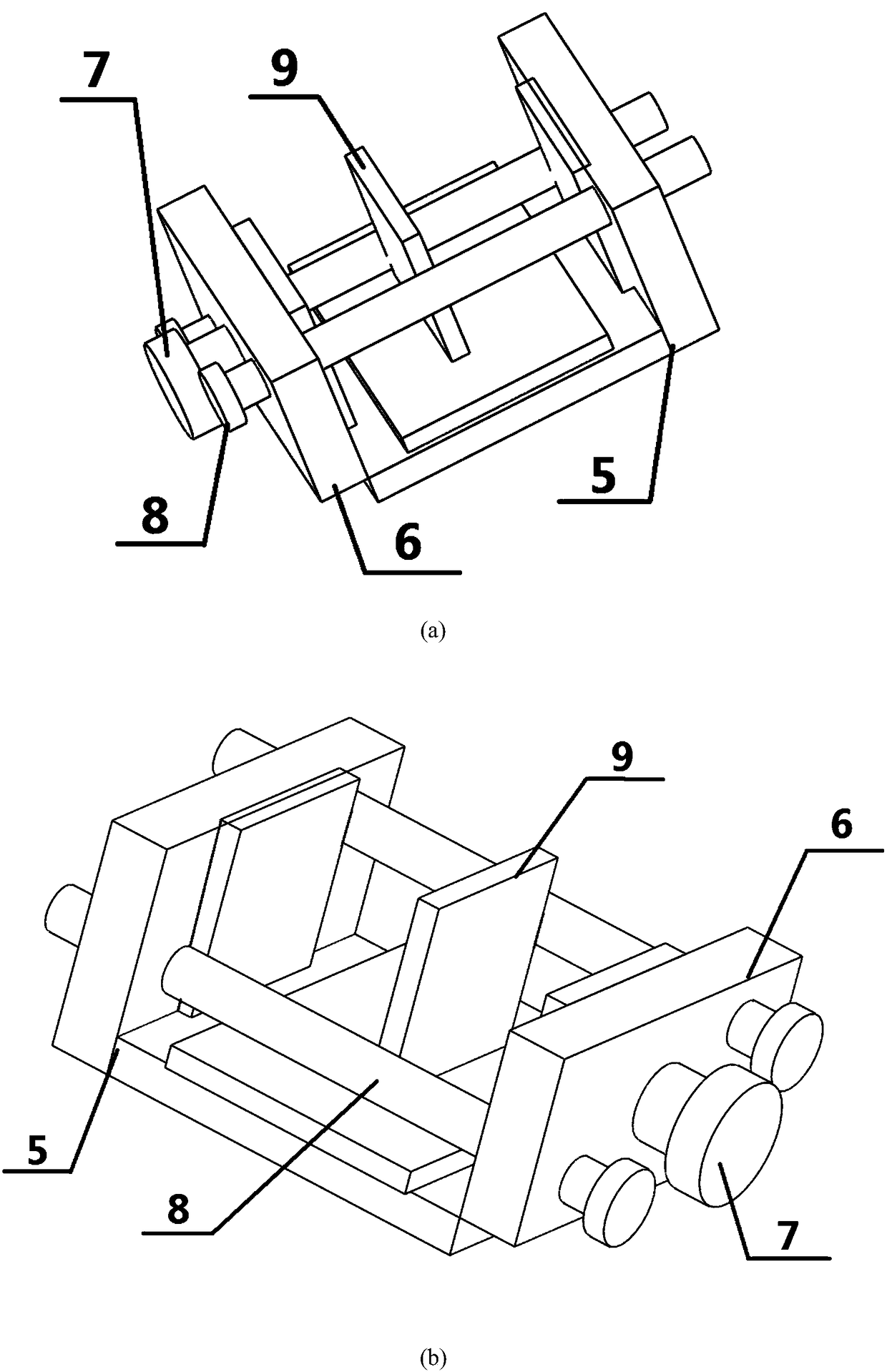

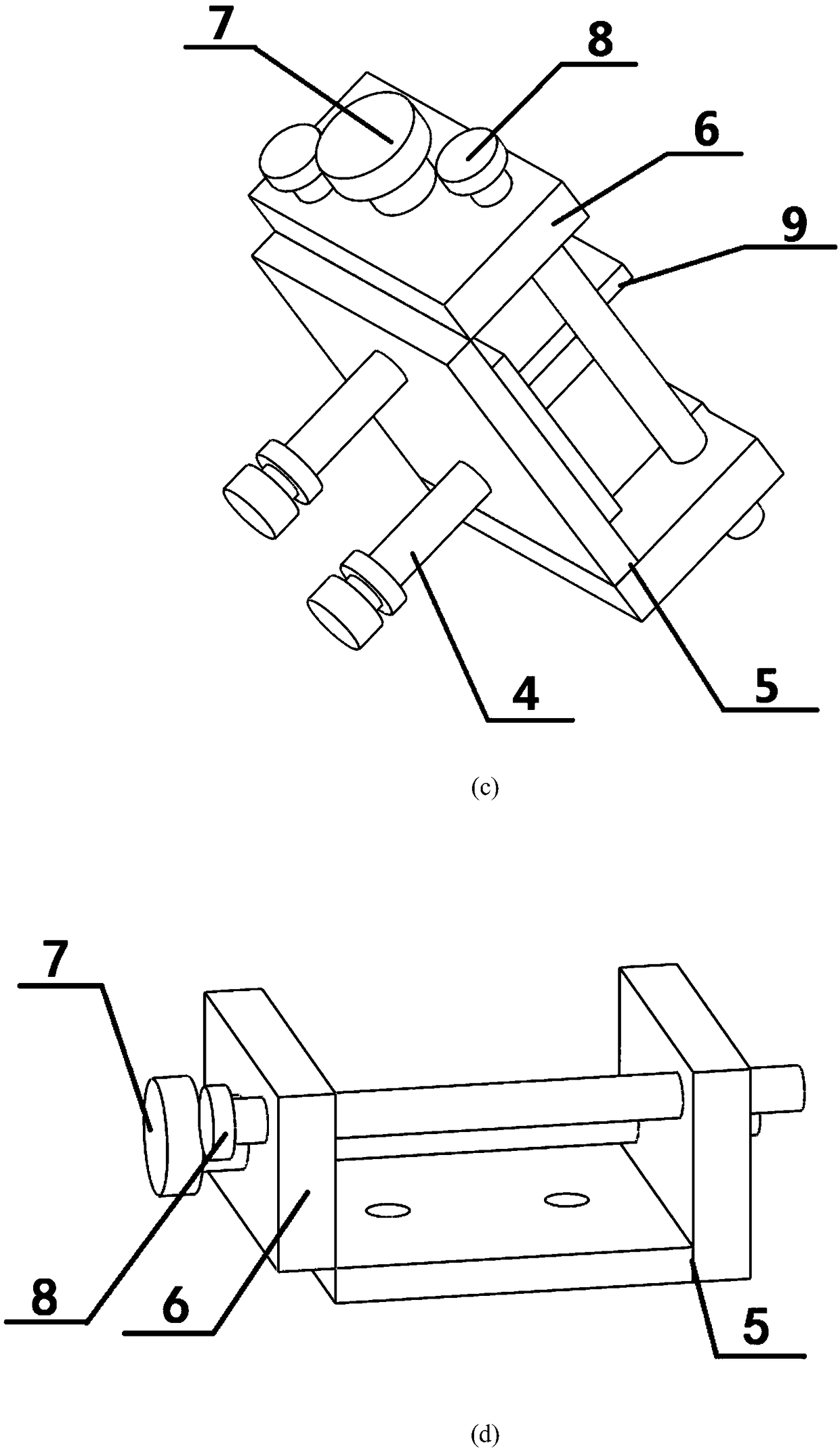

[0024] Such as figure 2 The clamp body 2 shown in (a) to (d) includes: clamping front pressure plate 6, L-shaped clamping rear bottom plate 5, connecting screw 8 and clamping screw 7, clamping front pressure plate 6 and clamping rear bottom plate 5 is connected and fixed by the connecting screw 8, and the arc-shaped abrasive block 11 is clamped between the clamping front pressure plate 6 and the clamping rear bottom plate 5; The clamping force is adjusted by clamping screw 7, such as figure 2 (a) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com