A nanobubble generator

A nano-bubble and generator technology, used in solid separation, flotation and other directions, can solve the problems of large size of foam and inability to fully recover fine-grained minerals, achieve large bubble volume, stable size, and improve flotation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

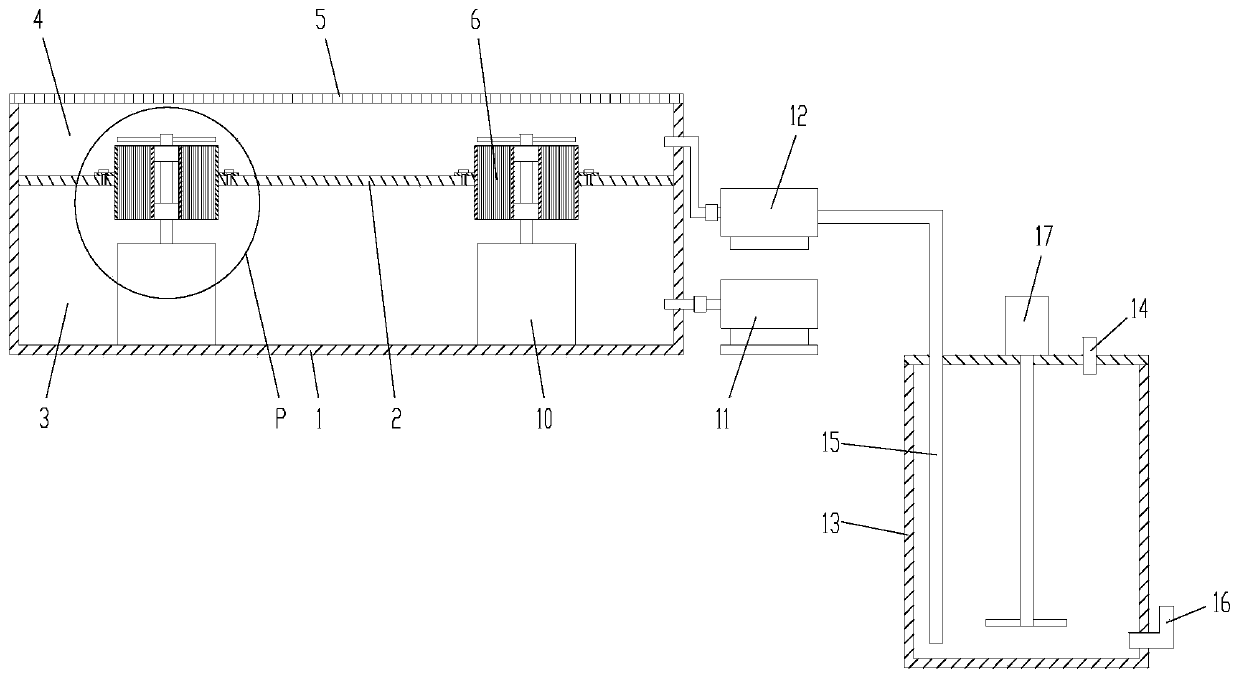

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

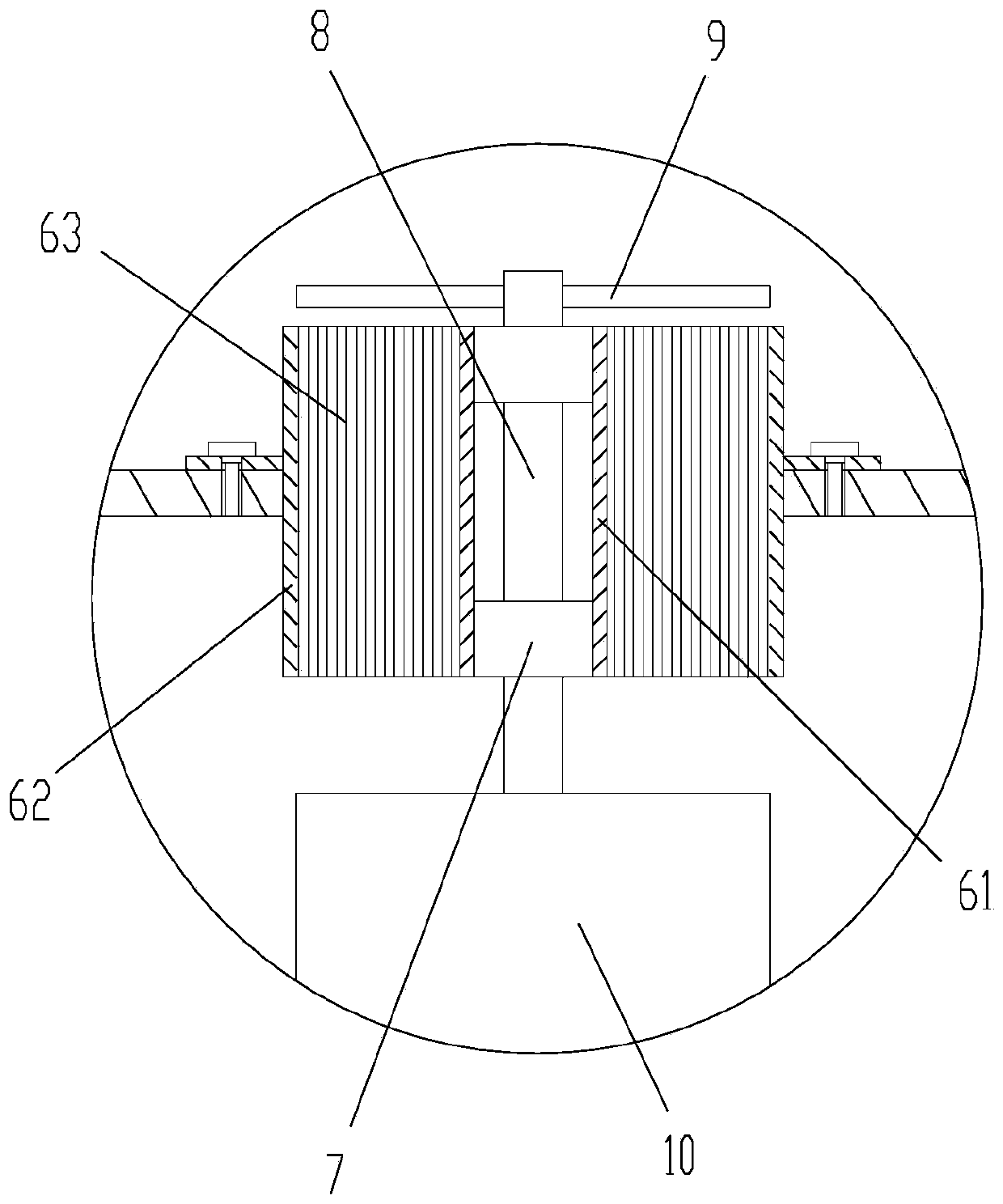

[0023] As shown in the figure, the nanobubble generator of this embodiment includes a casing 1 with an upper opening, and a horizontal partition 2 is arranged in the middle of the casing, and the horizontal partition divides the casing into upper and lower parts. The lower part is an air chamber 3, and the upper part is a gas-liquid mixing chamber 4. The upper end of the housing is also provided with a filter plate 5, which is used to prevent particles from falling into the gas-liquid mixing chamber.

[0024] The nanobubble generator also includes several micro-flow tubes 6 evenly arranged on the horizontal partition, and the micro-flow tubes include an inner tube 61, an outer tube 62, and a copper foil arranged between the inner tube and the outer tube Roll 63, the copper foil roll is made of copper foil etched with micro-airflow channels on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com