Bridge frame fish-bone structure

A fishbone and bridge technology, applied in the direction of electrical components, etc., can solve the problems of complex structure and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] To illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] It should be noted that the bridge structure of the present invention can be used in an underground garage lighting system, and the bridge is used to install light-emitting lamps to emit light, but it does not limit the scope of the patent of the present invention. Any equivalent structure made using the contents of the specification and drawings of the present invention Or equivalent process changes, or directly or indirectly used in other related technical fields, are similarly included in the scope of patent protection of the present invention.

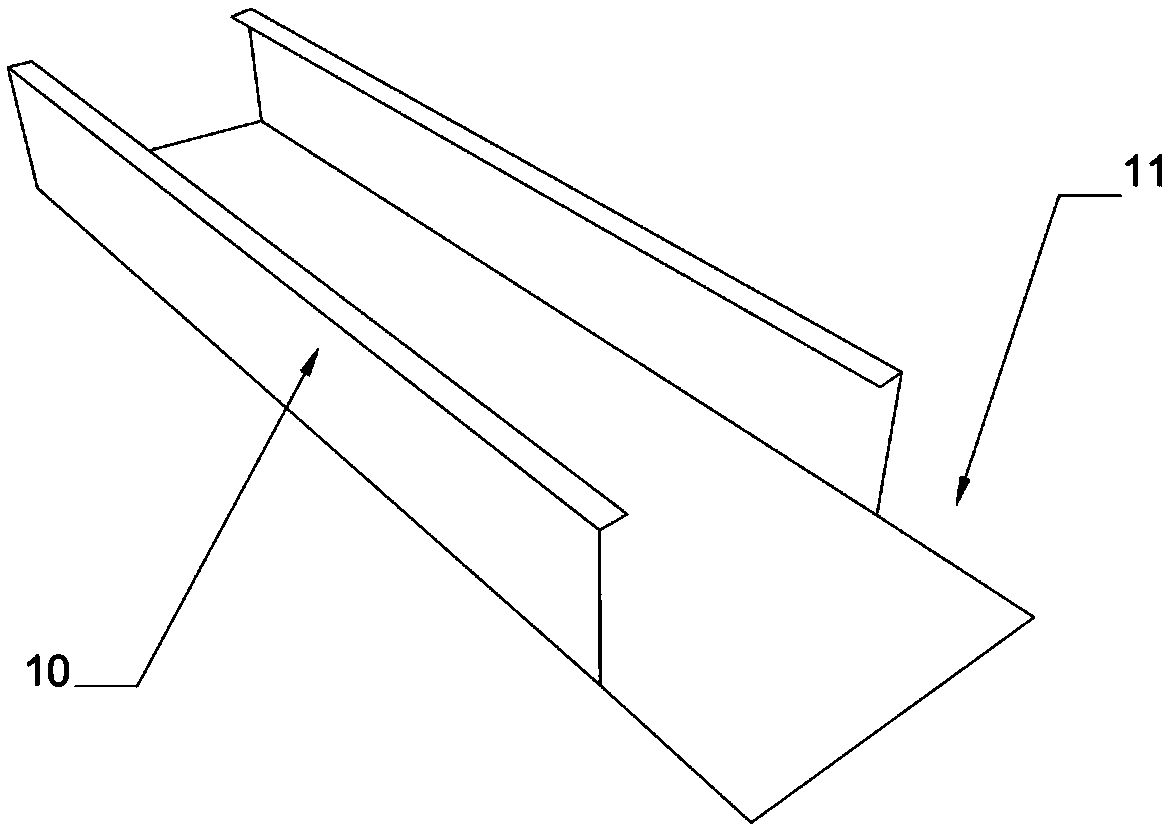

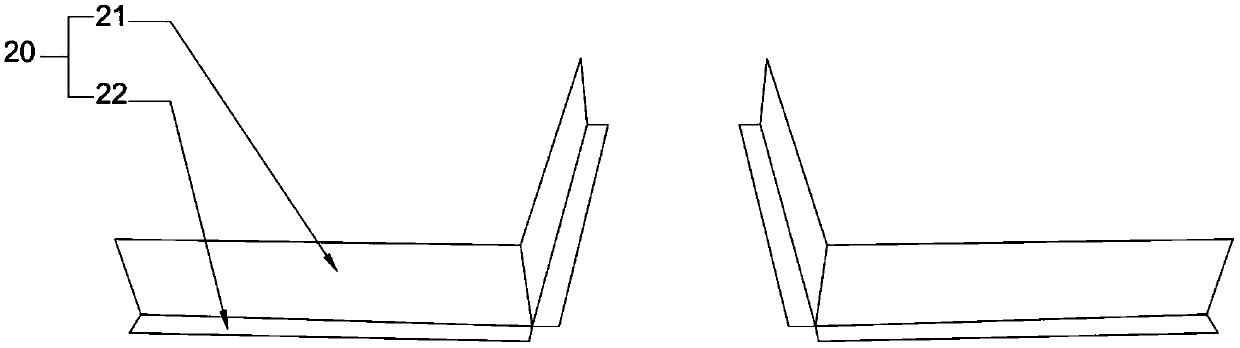

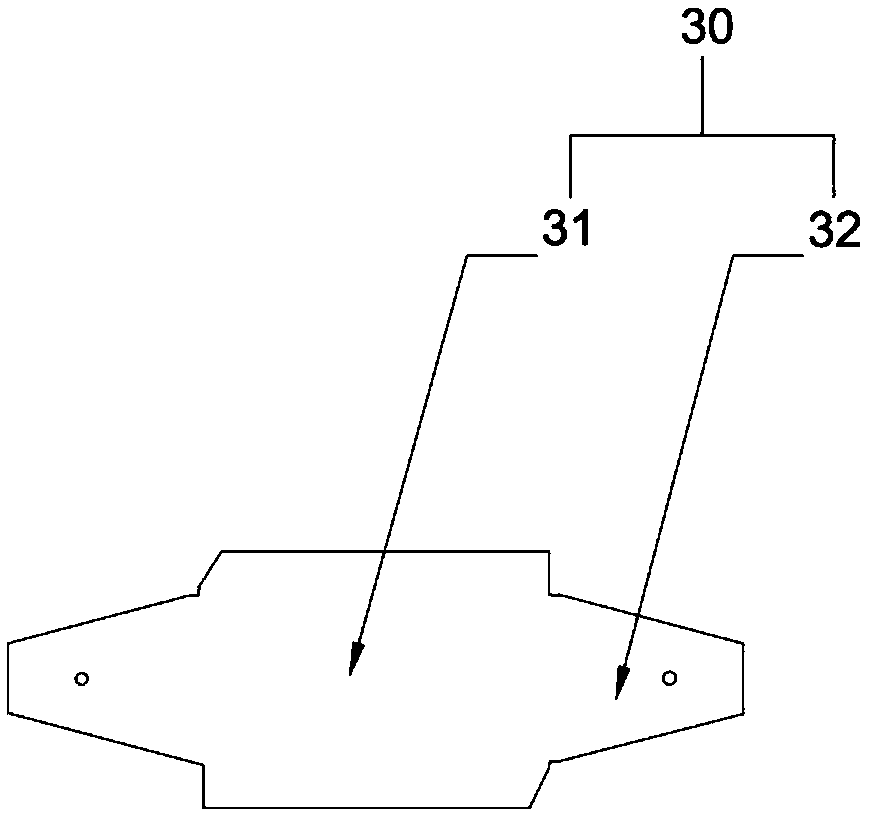

[0019] Reference Figure 1-5 A specific embodiment of the present invention proposes a fishbone structure for a bridge frame, which includes a main line groove 10, a side rod 40 and an angle connector 20. The side wall of the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com