Silkworm cocoon processing method capable of increasing reelability percentage and silk yield of silkworm cocoons

A processing method and technology of unwinding rate, applied in the agricultural field, can solve problems such as unwinding rate and low silk yield, and achieve the effects of promoting silk reeling performance, improving cocoon cooking effect and improving unwinding rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

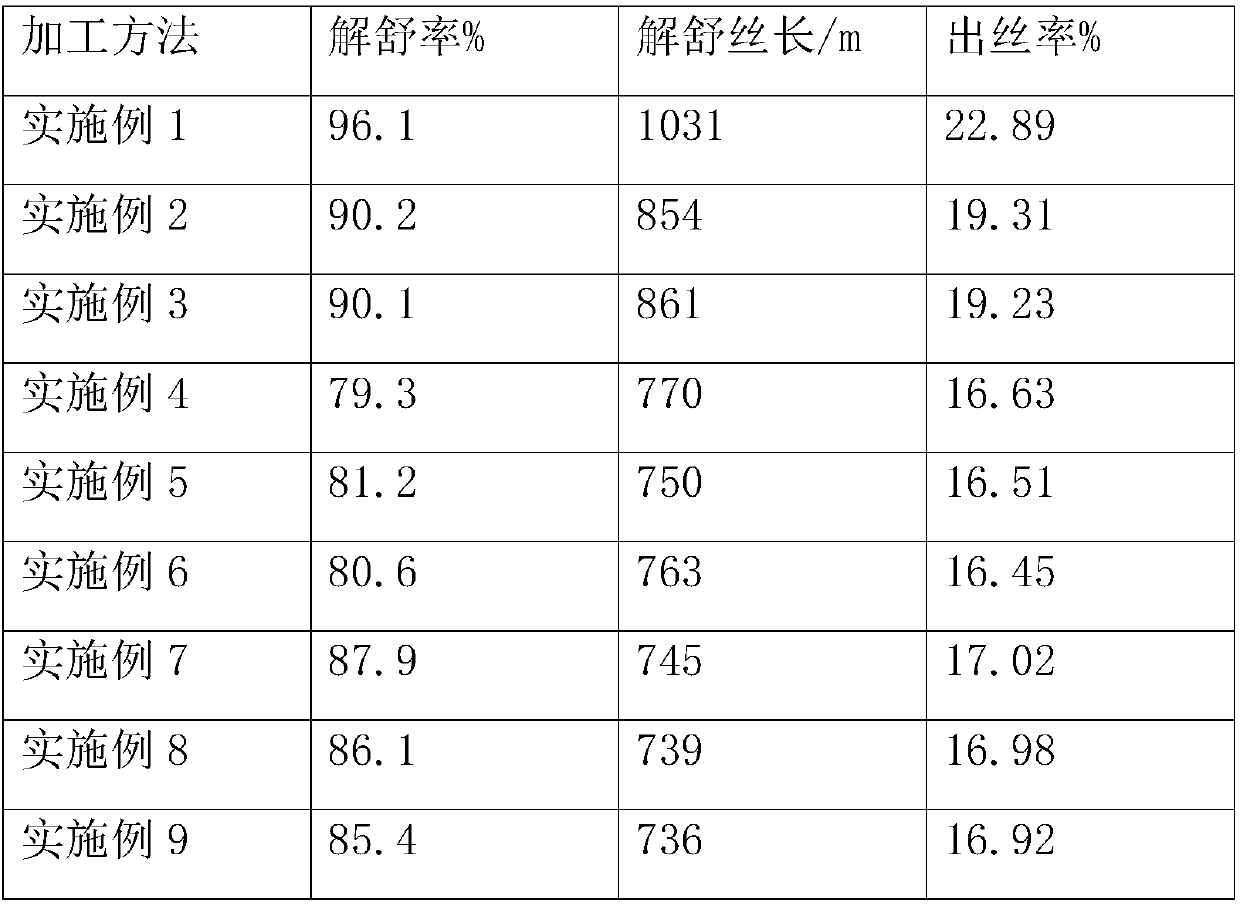

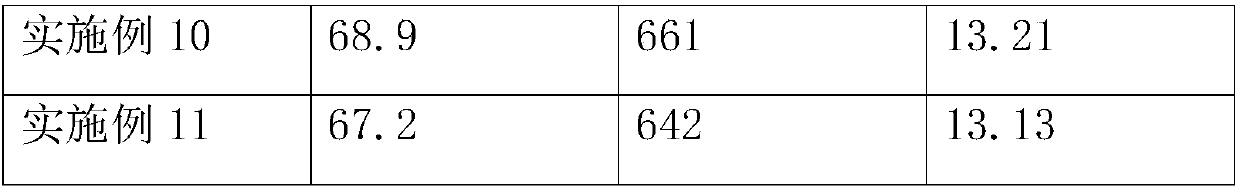

Examples

Embodiment 1

[0025] A method for processing silkworm cocoons to improve the unwinding rate and silk yield of silkworm cocoons, the processing method comprising:

[0026] ①Place the fresh cocoons under the conditions of light intensity of 2700-3100lux to select, and remove the secondary cocoons, double cocoons, and lower rotten cocoons;

[0027] ②Put the silkworm cocoon through step ① into the vacuum pump first, and then after the vacuum pump is evacuated to 0.0101-0.0102Mpa, add the coco-based glucoside aqueous solution with a concentration of 6.1wt% at 32-35°C. ~8cm, the time of penetration and water absorption is 6~10min;

[0028] ③ Boil the cocoons of the silkworm cocoons that have passed step ②. When cooking the cocoons, control the temperature of the cocoon boiling water to 55-65°C, the time to 6-8 minutes, and the pH to be 5.2;

[0029] ④Put the cocoons of step ③ into warm water at 25°C to 30°C, and then add auxiliary agent 2 with a mass of 0.72% of the warm water, wherein auxiliary...

Embodiment 2

[0032] A method for processing silkworm cocoons to improve the unwinding rate and silk yield of silkworm cocoons, the processing method comprising:

[0033] ①Place the fresh cocoons under the conditions of light intensity of 2700-3100lux to select, and remove the secondary cocoons, double cocoons, and lower rotten cocoons;

[0034] ②Put the silkworm cocoon through step ① into the vacuum pump first, and then after the vacuum pump is evacuated to 0.0101-0.0102Mpa, add an aqueous solution of sodium dodecylsulfonate with a concentration of 4.9-7.8wt% at 32-35°C. 6-8cm higher than the cocoon, the time for penetration and water absorption is 6-10 minutes;

[0035] ③ Boil the cocoons of the silkworm cocoons that have passed step ②. When cooking the cocoons, control the temperature of the cocoon boiling water to 55-65°C, the time to 6-8 minutes, and the pH to be 5.2;

[0036] ④Put the cocoons of step ③ into warm water at 25°C to 30°C, and then add auxiliary agent 2 with a mass of 0.7...

Embodiment 3

[0039] A method for processing silkworm cocoons to improve the unwinding rate and silk yield of silkworm cocoons, the processing method comprising:

[0040] ①Place the fresh cocoons under the conditions of light intensity of 2700-3100lux to select, and remove the secondary cocoons, double cocoons, and lower rotten cocoons;

[0041] ②Put the silkworm cocoon through step ① into the vacuum pump first, and then after the vacuum pump is evacuated to 0.0101-0.0102Mpa, add an aqueous solution of fatty acid glyceride with a concentration of 4.9-7.8wt% at 32-35°C. ~8cm, the time of penetration and water absorption is 6~10min;

[0042] ③ Boil the cocoons of the silkworm cocoons that have passed step ②. When cooking the cocoons, control the temperature of the cocoon boiling water to 55-65°C, the time to 6-8 minutes, and the pH to be 5.2;

[0043] ④Put the cocoons of step ③ into warm water at 25°C to 30°C, and then add auxiliary agent 2 with a mass of 0.72% of the warm water, wherein aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com