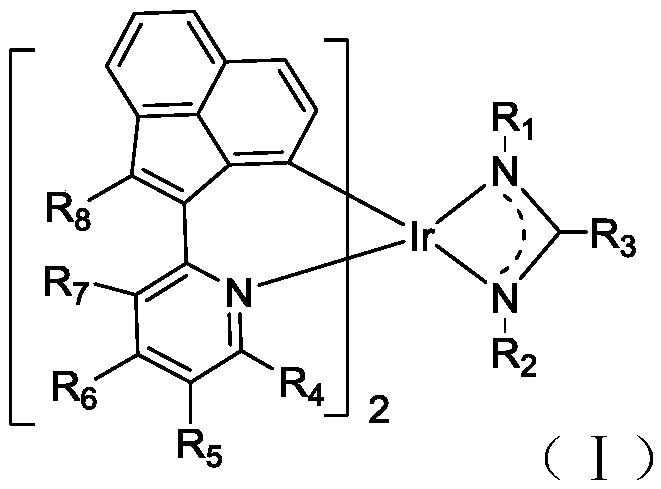

Organic iridium-containing metal complex and organic light-emitting device thereof

An iridium metal complex and organic technology, applied in the direction of indium organic compounds, platinum group organic compounds, luminescent materials, etc., can solve the problems that high-performance red phosphorescent materials need to be further developed, and meet the needs of industrialization and easy raw materials The effect of easy film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

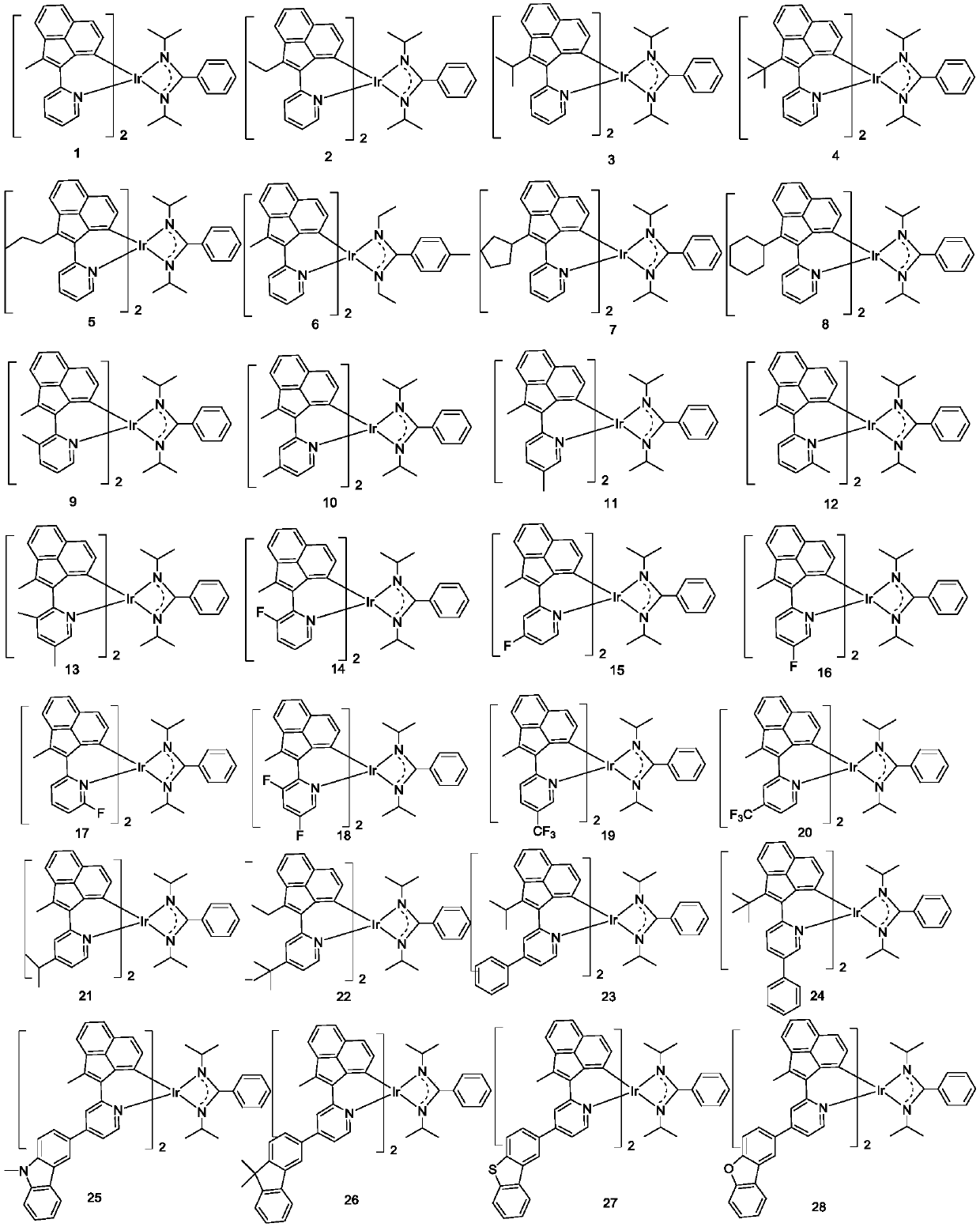

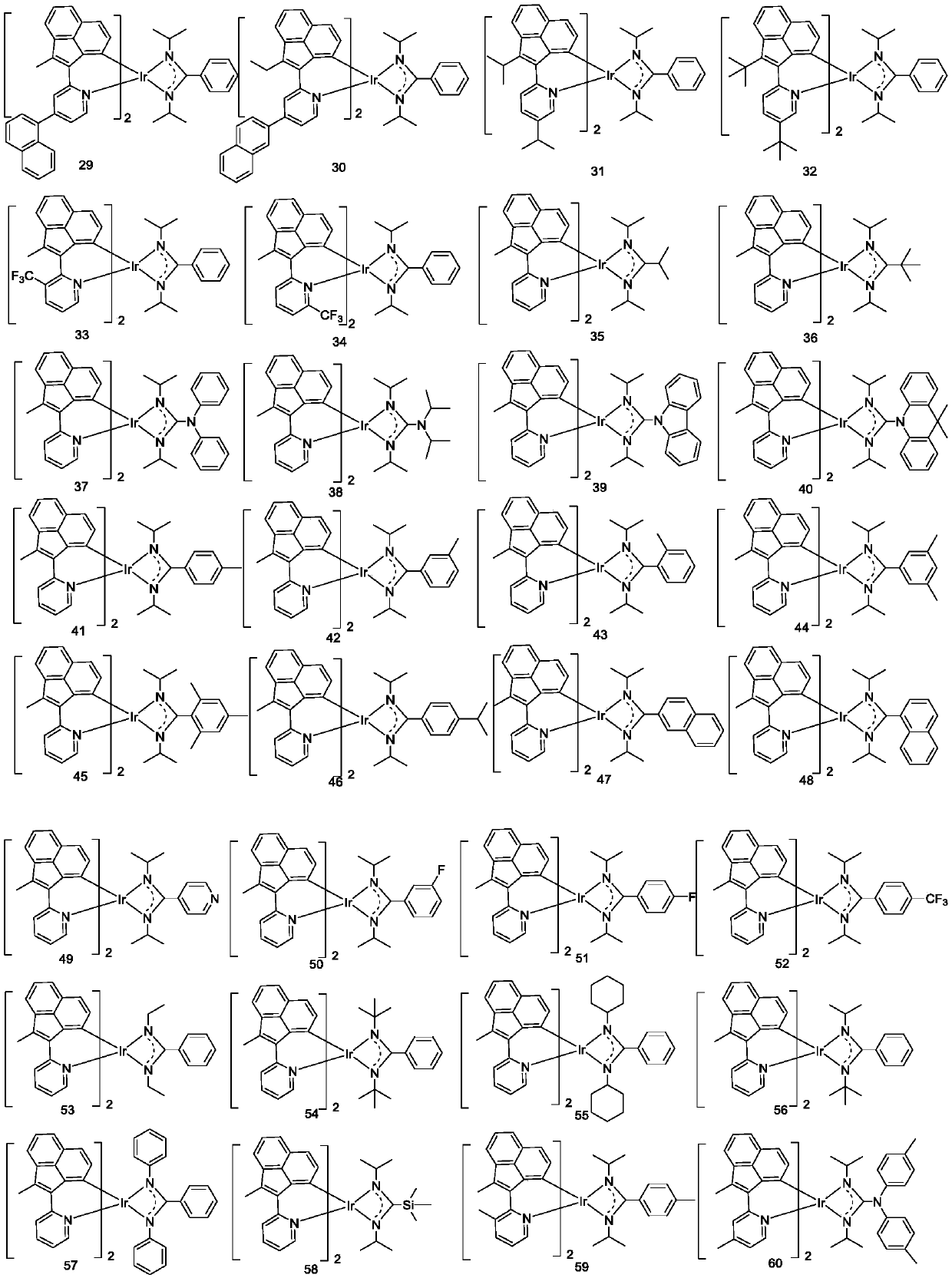

Examples

Embodiment 1

[0068] Embodiment 1: the preparation of compound 1

[0069]

[0070] Preparation of intermediate A1

[0071] Take acenaphthene (0.1mol, 15.5g) and dissolve it in 500ml of glacial acetic acid, heat up the oil bath to 40°C, add 15.5ml of PEG400, stir and react for 30 minutes, then add 60g of chromium trioxide in batches, after the addition is complete, keep warm and stir React for 8 hours, cool to room temperature, add 5000ml of ice water to dilute, extract with ethyl acetate, dry the organic phase with anhydrous sodium sulfate, filter, concentrate and dry under reduced pressure, separate and purify with a silica gel column to obtain 16.4g of white solid b1.

[0072] Dissolve 15gb1 in 100ml of anhydrous THF, under the protection of nitrogen, cool down to 0°C in an ice-water bath, add 35.5mmol of methylmagnesium iodide THF solution, stir for 30 minutes, rise to room temperature and stir for 1 hour, add 50ml of 3M Dilute hydrochloric acid aqueous solution, stir and react for 3...

Embodiment 2

[0082] Embodiment 2: the preparation of compound 10

[0083] The f1 in Example 1 was replaced by equimolar f10, and the other steps were the same as in Example 1 to obtain the target compound 10 (5.09 g, 28%).

[0084]

[0085] Mass Spectrum m / z: 909.36 (calculated: 909.35). Theoretical element content (%)C 51 h 48 IrN 4 : C, 67.37; H, 5.32; Ir, 21.14; N, 6.16 The measured element content (%): C, 67.38; H, 5.32; Ir, 21.14; N, 6.15. The above results confirmed that the obtained product was the target product.

Embodiment 3

[0086] Embodiment 3: the preparation of compound 13

[0087] The f1 in Example 1 was replaced by equimolar f13, and the other steps were the same as in Example 1 to obtain the target compound 13 (5.62 g, 30%).

[0088]

[0089] Mass Spectrum m / z: 937.39 (calculated: 937.38). Theoretical element content (%)C 53 h 52 IrN 4 : C, 67.92; H, 5.59; Ir, 20.51; N, 5.98 Measured element content (%): C, 67.93; H, 5.59; Ir, 20.51; N, 5.97. The above results confirmed that the obtained product was the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com