Negative ion titanium brick and production technology thereof

A preparation process and negative ion technology, which is applied in the field of building materials, can solve the problems of poor mechanical properties such as strength and no health care functions, and achieve the effects of improving gloss, increasing aesthetics, and removing toxic and harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

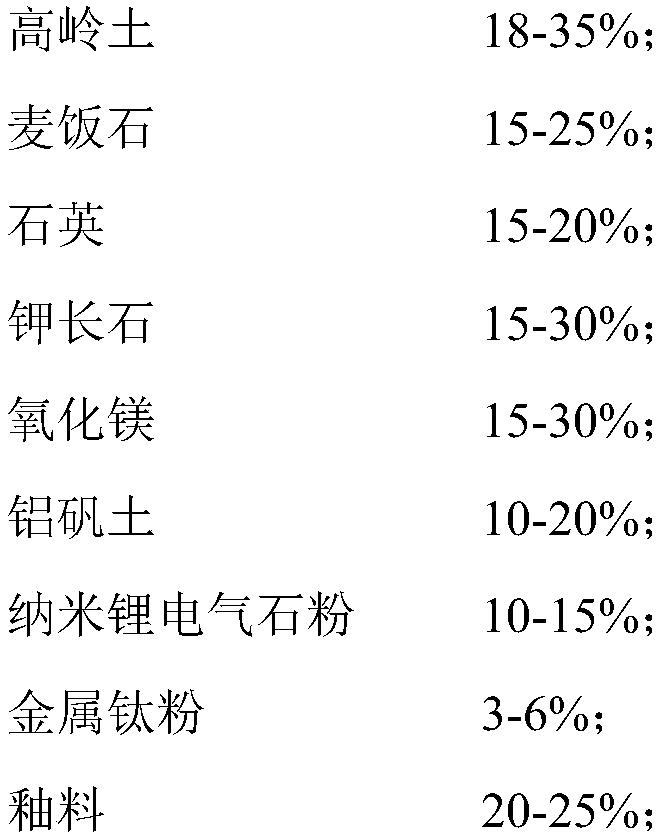

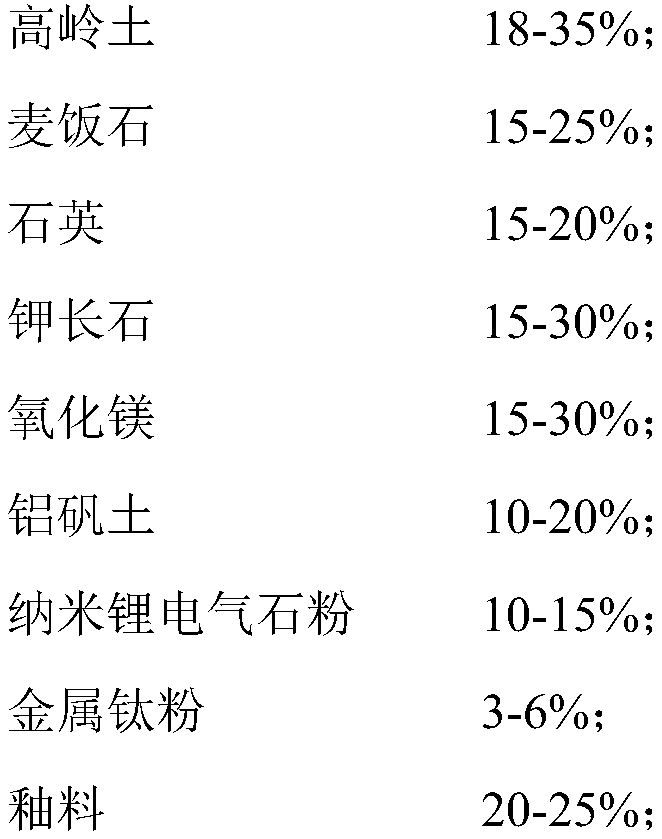

Method used

Image

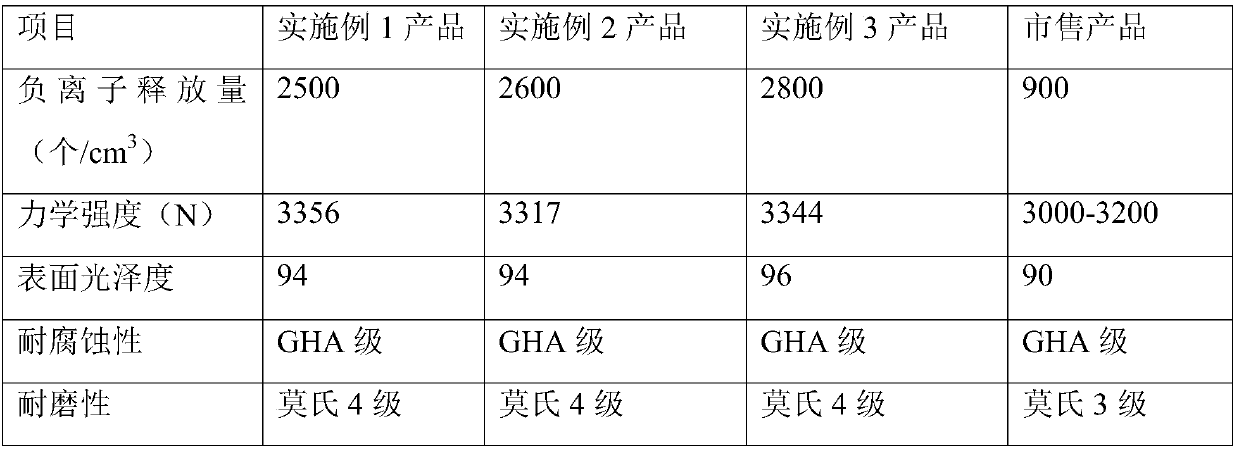

Examples

Embodiment 1

[0039] Weigh each material of following quality, take kg as unit: Kaolin 20; Medical stone 15; Quartz 15; Potassium feldspar 20; Magnesium oxide 15; Bauxite 10;

[0040] Metal titanium powder 3;

[0041] The mass of glaze constituents, in kg: kaolin 10; quartz 15; bauxite 10; nano lithium tourmaline powder 5; carbon fiber 10; modified polybutadiene resin 10.

[0042] Prepare as follows:

[0043] 1: Mix the weighed kaolin, medical stone, quartz, potassium feldspar, magnesium oxide, bauxite and nano-lithium tourmaline powder, add water ball mill, mill for 6 hours, and then sieve to remove iron, sieve 100 1. Spray drying at 730°C. After silo stale for 2 days, the temperature is 80°C, and press molding;

[0044] 2: Put the weighed kaolin, quartz, bauxite, nano-lithium tourmaline powder, carbon fiber and modified polybutadiene resin into water and ball mill, ball mill for 10 hours, the ball mill temperature is 50 ℃, and ultrasonic emulsify for 20 hours after ball milling to obtai...

Embodiment 2

[0050] Weigh each material of following quality, take kg as unit: Kaolin 30; Medical stone 15; Quartz 17; Potassium feldspar 20; Magnesium oxide 20; Bauxite 10;

[0051] Metal titanium powder 6;

[0052] The mass of the constituent substances of the glaze, in kg: kaolin 15; quartz 15; bauxite 15; nano lithium tourmaline powder 15; carbon fiber 15; cellulose resin 15.

[0053] Prepare as follows:

[0054] 1: Mix the weighed kaolin, medical stone, quartz, potassium feldspar, magnesia, bauxite and nano-lithium tourmaline powder, add water ball mill, mill for 7 hours, then sieve to remove iron, sieve 150 For this purpose, it is spray-dried at 700°C, and after the silo is stale for 1 day, the temperature is 70°C, and it is pressed into shape;

[0055] 2: Put the weighed kaolin, quartz, bauxite, nano-lithium tourmaline powder, carbon fiber and cellulose resin into water and ball mill, ball mill for 15 hours, the ball mill temperature is 60°C, after ball milling, ultrasonic emulsif...

Embodiment 3

[0061] Take by weighing each material of following quality, take kg as unit: Kaolin 18; Medical stone 25; Quartz 16; Potassium feldspar 18; Magnesium oxide 15; Bauxite 18;

[0062] Metal titanium powder 4;

[0063] The mass of glaze components, in kg: kaolin 14; quartz 16; bauxite 13; nano lithium tourmaline powder 16; carbon fiber 9; silicone resin 12.

[0064] Prepare as follows:

[0065]1: After mixing the weighed kaolin, medical stone, quartz, potassium feldspar, magnesia, bauxite and nano-lithium tourmaline powder, add water ball mill, ball mill for 7 hours, then sieve to remove iron, sieve 100 1. Spray drying at 680°C, silo stale for 1.5 days, press molding at 75°C;

[0066] 2: Put the weighed kaolin, quartz, bauxite, nano-lithium tourmaline powder, carbon fiber and silicone resin into water and ball mill, ball mill for 14 hours, the ball milling temperature is 50°C, and ultrasonic emulsify for 20 hours after ball milling to obtain the glaze;

[0067] 3: After the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com