Industrial sludge processing device

A technology of sludge treatment and treatment equipment, which is applied in the direction of sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc. It can solve the problems of no shock absorption, troublesome movement and transportation, and complicated structure. Achieve the effects of easy movement and transportation, good wear resistance and corrosion resistance, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

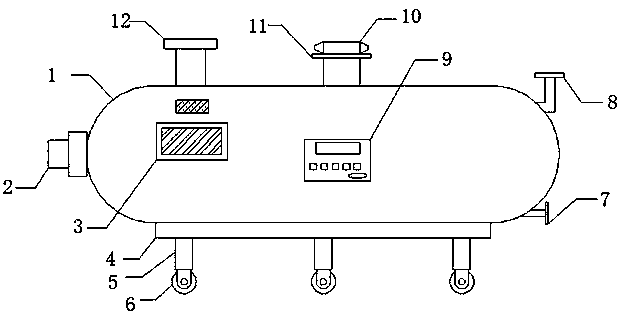

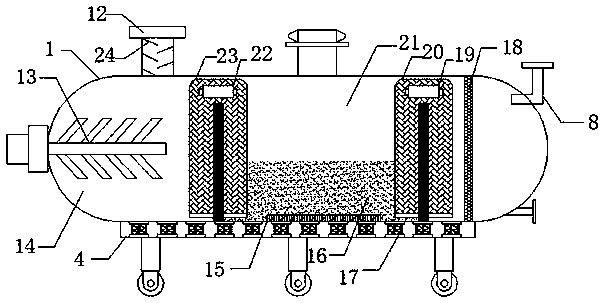

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

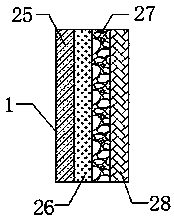

[0019] Such as Figure 1-3 As shown, an industrial sludge treatment device includes a sludge treatment barrel 1, a treatment barrel base 4, a crushing chamber 14, and a contact oxidation chamber 21. The sludge treatment barrel 1 is provided with a crushing chamber 14 on one side, and the crushing A stirring motor 2 is installed on one side of the chamber 14 through a mounting seat, and a stirring rod 13 is installed on one side of the crushing chamber 14 through a connecting rod, and one end of the stirring rod 13 is connected with the stirring end of the stirring motor 2, and one side of the crushing chamber 14 is provided with There is a contact oxidation chamber 21, and a coagulant 16 is provided in the contact oxidation chamber 21, a ceramic h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com