Machining mechanism for inner-outer double-layer anti-corrosive stainless steel drainage pipes, and machining method thereof

A technology of inner and outer double layers and processing mechanism, which is applied in the field of steel pipe processing, can solve the problems of unfavorable equipment integration, material layers are easy to fall off, and many processes, so as to achieve high integration, improve production effect, and improve uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

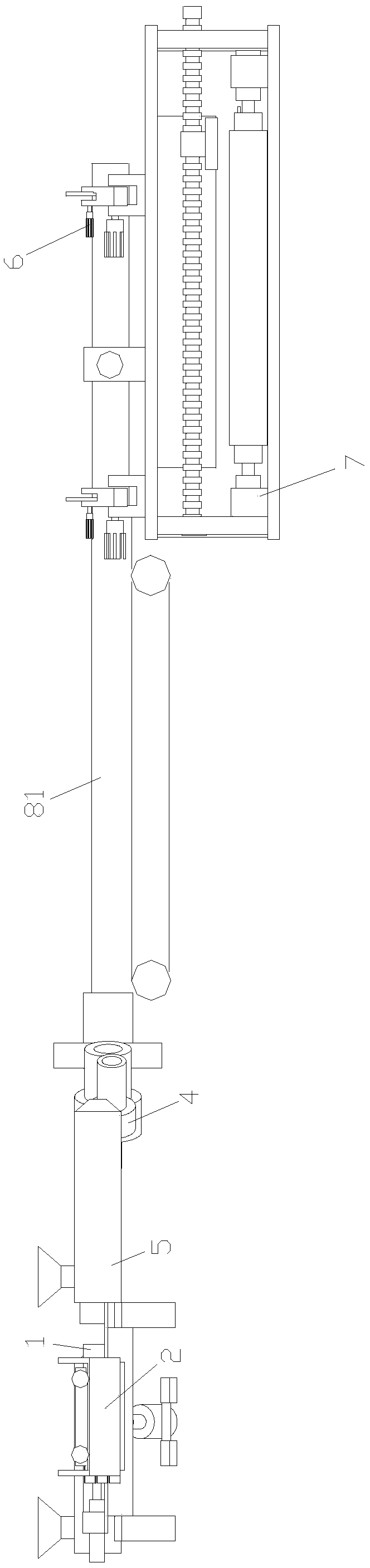

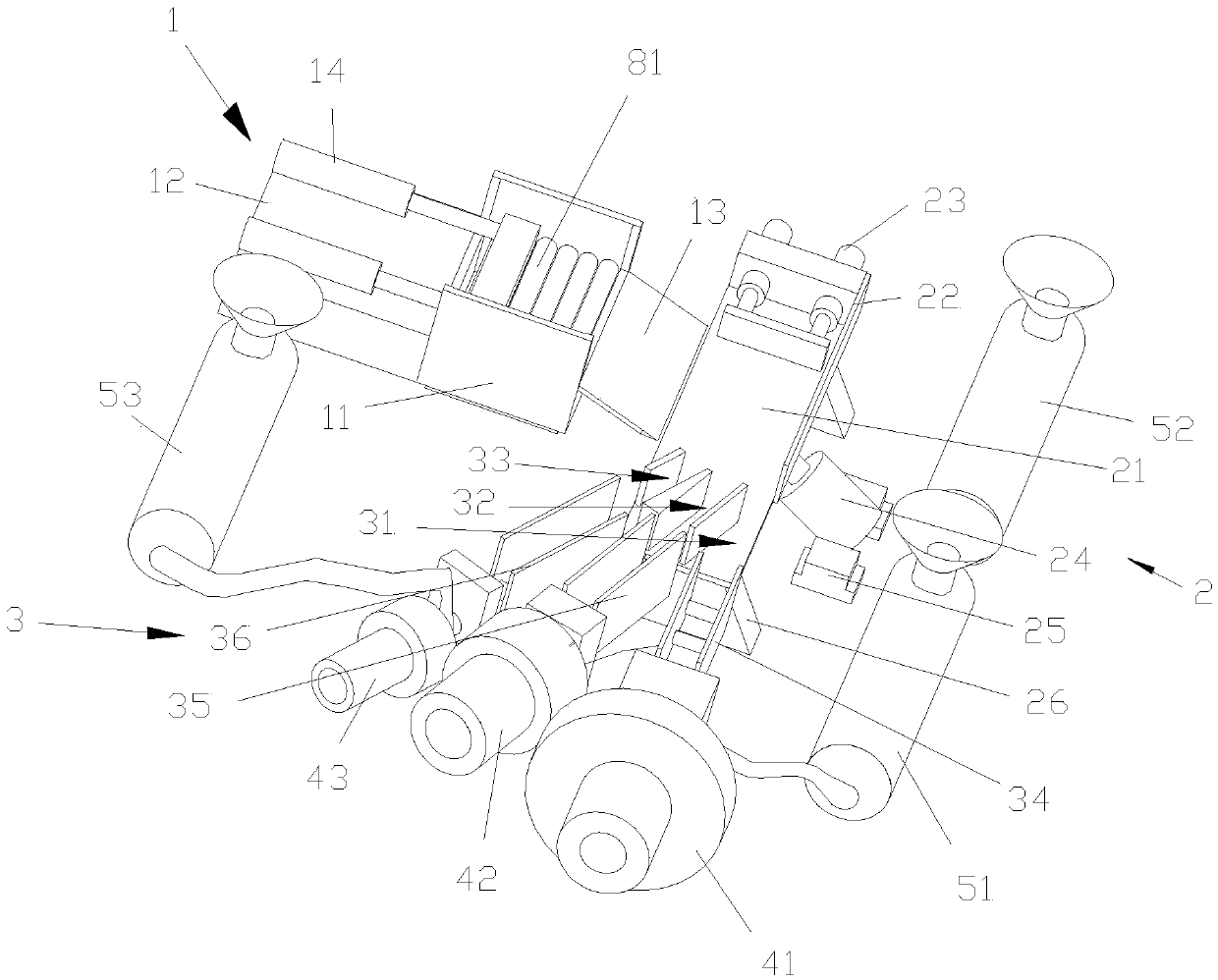

[0046] Such as Figure 1-2 As shown, this embodiment discloses a processing mechanism for inner and outer double-layer anti-corrosion stainless steel drainage pipes, including a stainless steel billet feeding device 1, an alignment pushing device 2, a multi-directional conduit device 3, a die head 4, an extruder 5, a cutting Material device 6, lining composite device 7. The stainless steel billet tube feeding device 1 is used to push a plurality of stainless steel billet tubes 81 stacked therein to the aligning push-out device 2 . The alignment pushing device 2 is used to align the multiple stainless steel blank tubes 81 fed therein and push the aligned stainless steel blank tubes 81 into the multi-directional conduit device 3 . The multidirectional conduit device 3 is used to adjust the conveying direction of multiple stainless steel blank tubes 81 and ensure that the conveying direction of each stainless steel blank tube 81 is different. The die head 4, the extruder 5 corr...

Embodiment 2

[0050] Such as Figure 4 As shown, the difference between this embodiment and the above-mentioned embodiment is that the stainless steel billet tube feeding device 1 includes a storage tube box 11, a tube feeding workbench 12, a lower tube inclined plate 13, a tube feeding pushing mechanism 14, and a tube feeding lifting device 15. The upper and lower ends of the storage pipe box body 11 are connected, and the upper ends of the left and right sides are open. Feeding tube lifting device 15 includes lifting support tube plate 151, feeding tube lifting mechanism 152, the telescoping end of feeding tube lifting mechanism 152 is connected with the bottom of lifting supporting tube plate 151, and the top surface of lifting supporting tube plate 151 extends into the storage tube box In the bottom opening of the body 11, the lifting movement of the telescopic end of the feeding pipe lifting mechanism 152 is used to drive the top surface of the lifting support tube plate 151 to move u...

Embodiment 3

[0054] Such as Figure 2-3 As shown, the difference between this embodiment and the above-mentioned embodiments is that the alignment push-out device 2 includes an alignment push-out workbench 21 , an alignment baffle 22 , and an alignment push-out mechanism 23 . Align and release the workbench 21 from the front to the back direction for its guidance. The alignment push-out mechanism 23 is located at the front end of the alignment push-out workbench 21, and the direction of the motion trajectory of its telescopic end is parallel to the guiding direction of the workbench. Alignment baffle plate 22 is installed on the front section or the front section to the middle section of its right side of alignment ejection workbench 21, or alignment baffle plate 22 extends to alignment ejection workbench 21 its right side from the front end of alignment ejection workbench 21 its right side. side rear end.

[0055]The multidirectional conduit device 3 comprises a plurality of guide plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com