Welding clamp for annular pieces and cylindrical pieces

A technology for welding fixtures and ring parts, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of manual station change, station switching, and station inability to achieve mechanical fixation, Achieve transformation and ensure efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

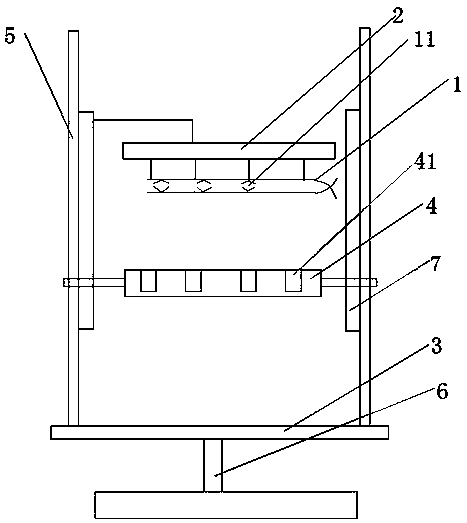

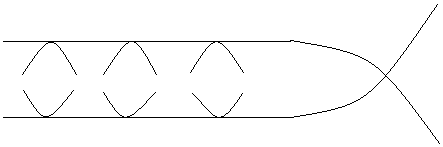

[0015] A welding jig for a ring and a column, comprising a first jig 1 capable of clamping a plurality of columns and a second jig 4 for clamping a plurality of rings, and also including fixing the first jig 1 and the second jig 4 The support includes a vertically arranged pole 5 and a horizontally arranged chassis 3, the pole 5 is provided with a slide rail 7, the first clamp 1 and the second clamp 4 are arranged up and down oppositely, the described The first clamp 1 can approach or move away from the second clamp 4 along the slide rail 7, the first clamp 1 includes a clip with a plurality of clamping holes 11, and the clip includes two symmetrically arranged bodies, The two pieces are provided with arc-shaped d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com