Automatic thermal cutting apparatus for riser of abrasion- resistant sleeve casting

A wear-resistant sleeve, thermal cutting technology, used in auxiliary devices, welding/cutting auxiliary equipment, gas flame welding equipment, etc. Guaranteed service life and the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

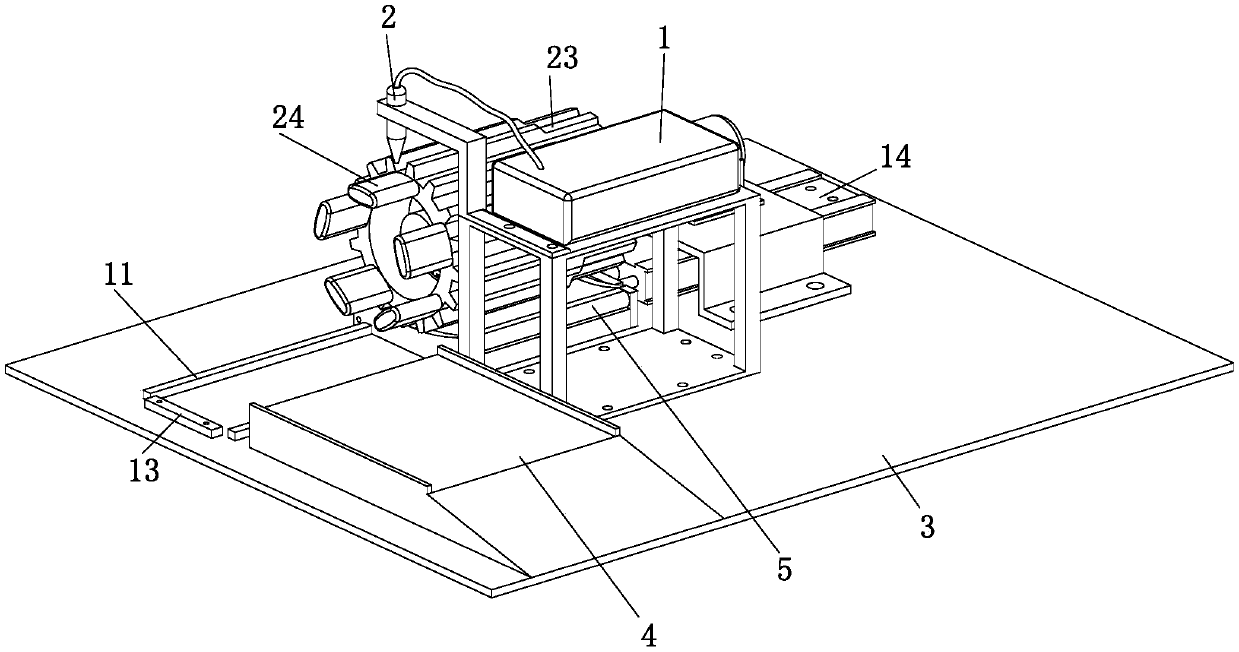

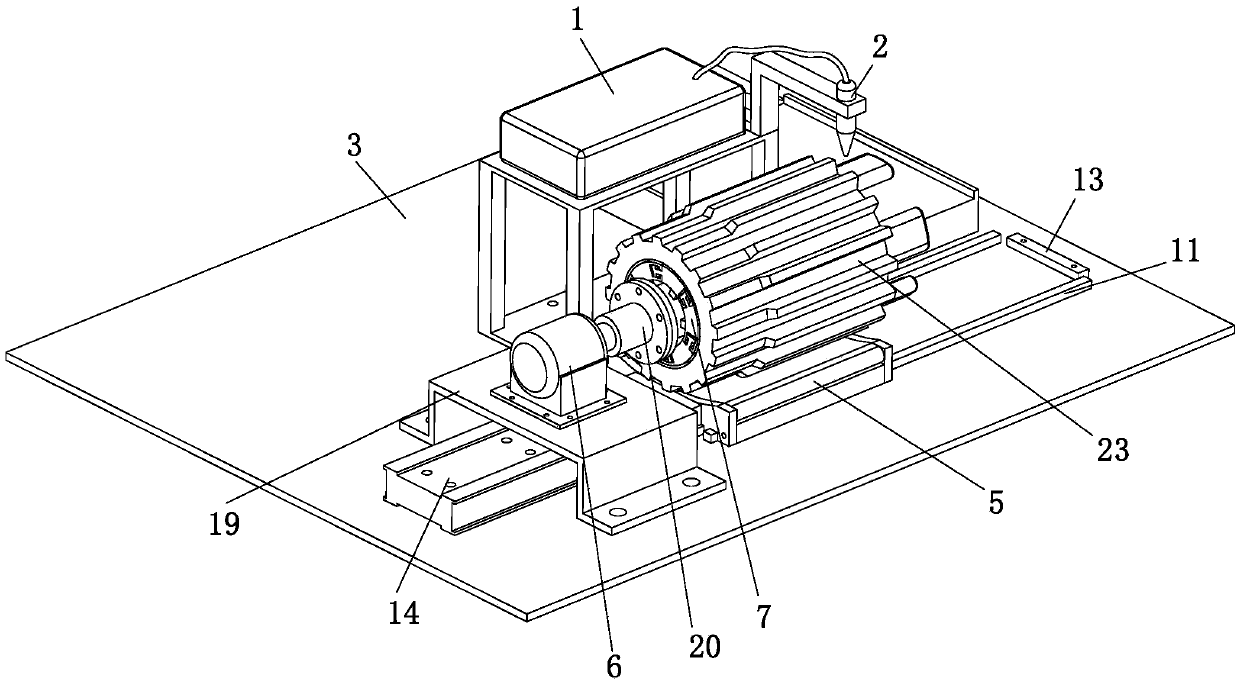

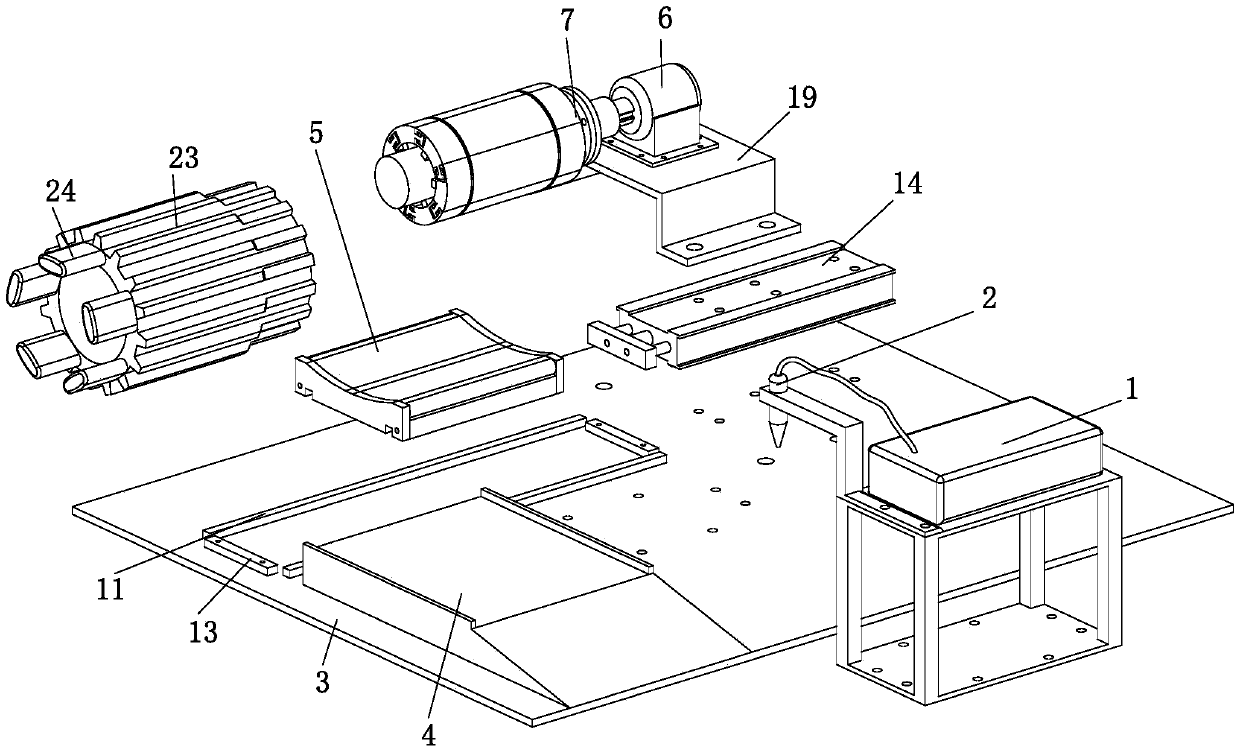

[0026] refer to Figure 1 to Figure 8 The shown automatic thermal cutting device for risers of wear-resistant sleeve castings includes a thermal cutting machine 1, and also includes a horizontally arranged base plate 3, a feeding trough 4, a material transfer mechanism and a uniform rotation mechanism, and the feed trough 4 and material transfer mechanism and the uniform rotation mechanism are all arranged on the top of the base plate 3, the material transfer mechanism includes a casting support table 5 that can move horizontally on the top of the base plate 3, the top of the casting support table 5 is a rotatable concave arc surface structure, and the concave arc surface structure The axis and the axis of the wear-resistant sleeve 23 are located in the same vertical plane, the casting support table 5 is located at ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap