Automatic processing equipment of wire stripping blade and cutting and milling angle control method thereof

A technology for automatic processing and cutting, which is applied in automatic control devices, metal processing equipment, milling machine equipment, etc., and can solve problems such as troublesome and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

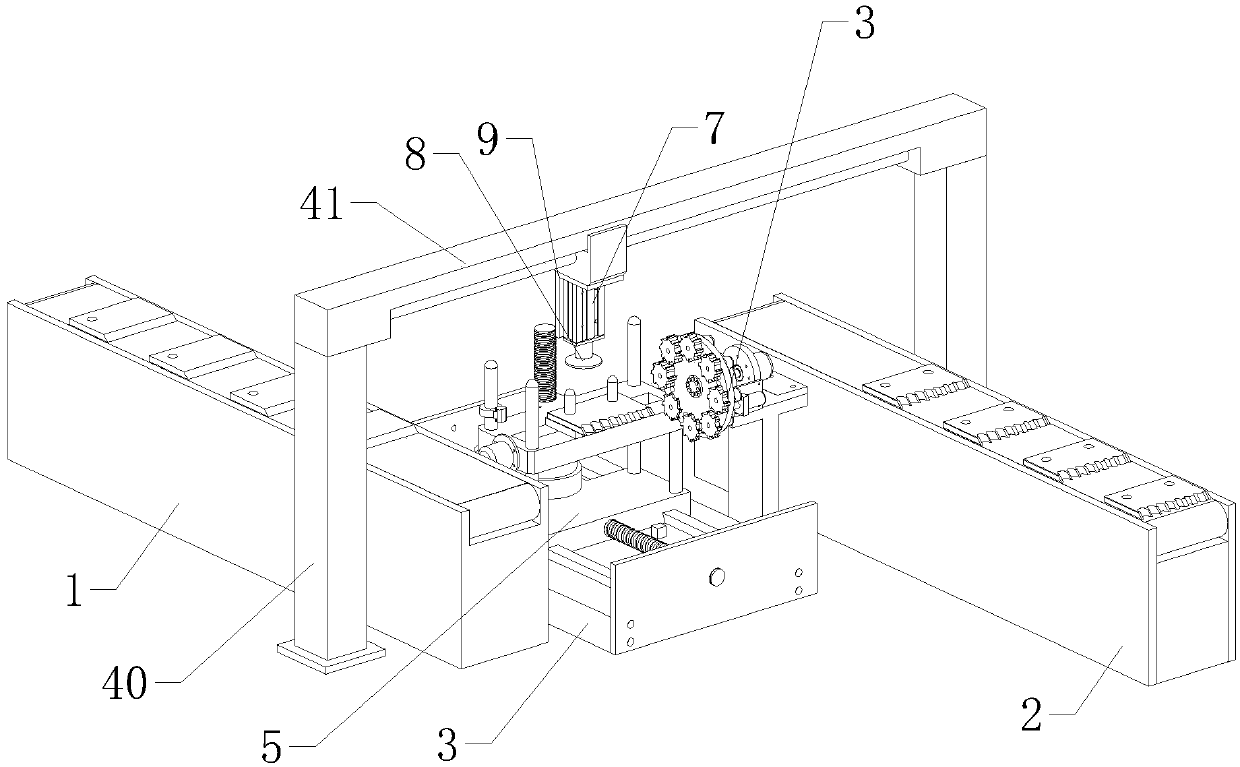

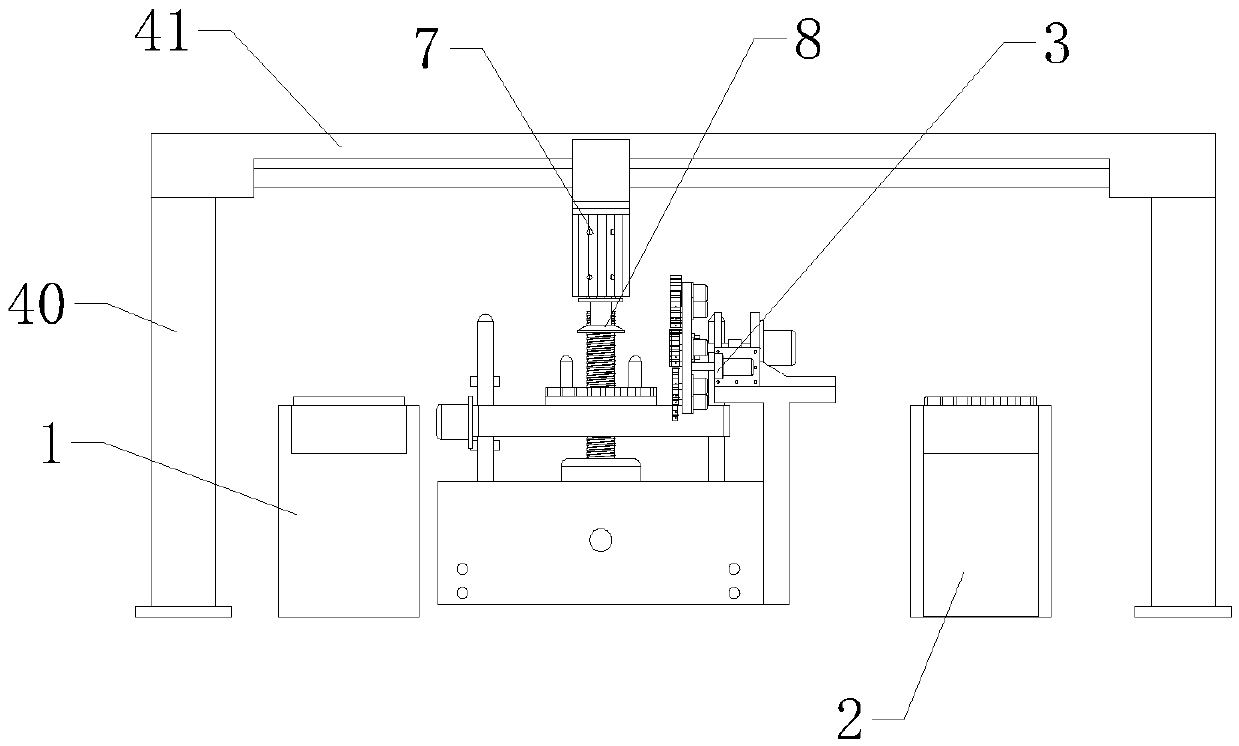

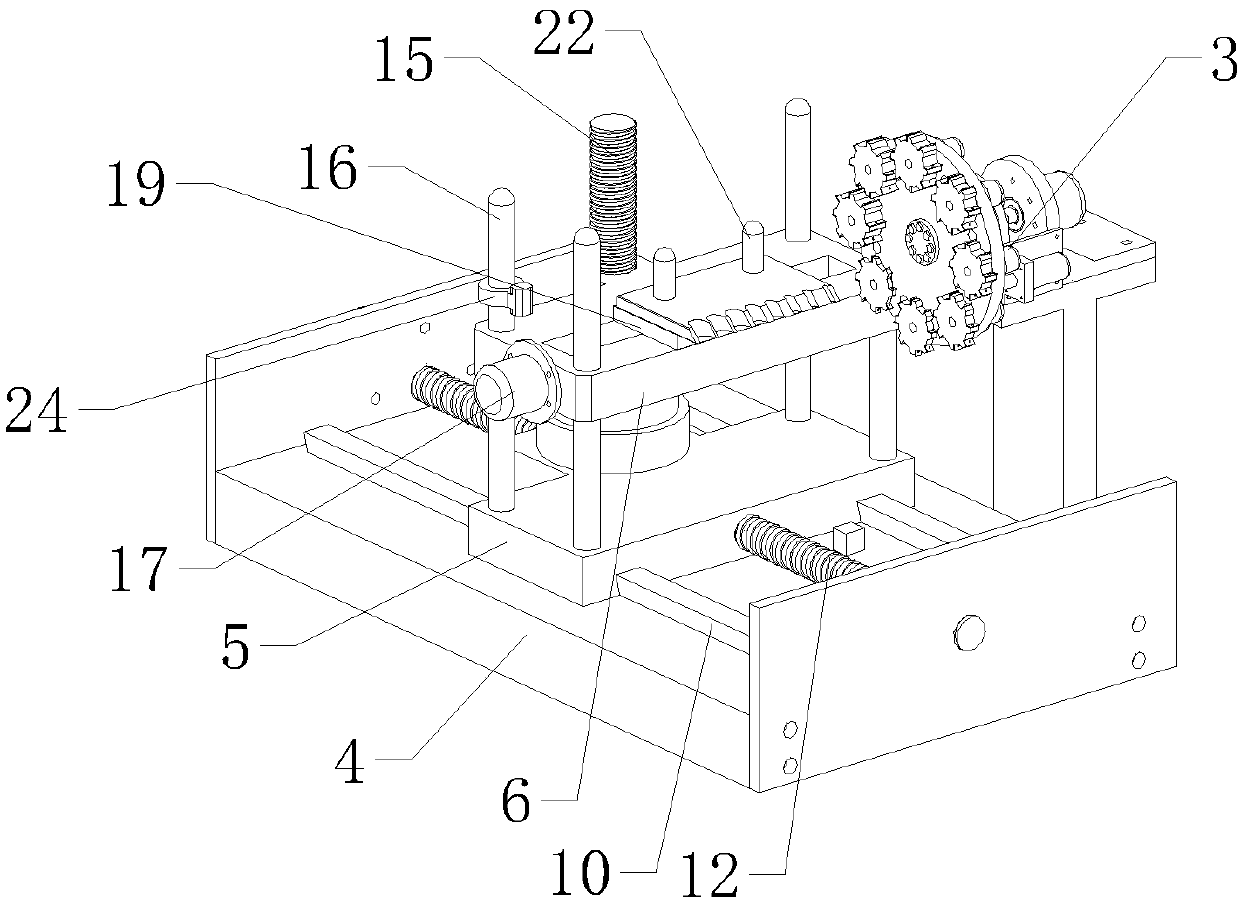

[0033] refer to Figure 1 to Figure 11 The shown automatic processing equipment for wire stripping blades includes an original conveyor belt 1, a finished product conveyor belt 2, a material transfer mechanism, a positioning mechanism, a three-axis speed regulating mechanism, and a cutting and milling mechanism 3. The original conveyor belt 1 and the finished product conveyor belt 2 are arranged parallel to each other. , the material shifting mechanism is set directly above the original conveyor belt 1 and the finished product conveyor belt 2, the positioning mechanism is set on the top of the three-axis speed regulating mechanism, and the cutting and milling mechanism 3 is set on the side of the three-axis speed regulating mechanism for the wire stripping blade The original is cut, the three-axis speed regulating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com