Connecting structure based on PTC carbon heating cable

A technology for heating cables and connecting structures, applied in the field of power cables, can solve the problems of poor waterproof and anti-shock effect, shortening the service life of heating cables, and cables being easily affected by water vapor, so as to reduce the probability of electric leakage and electric shock accidents. , prolong the service life, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

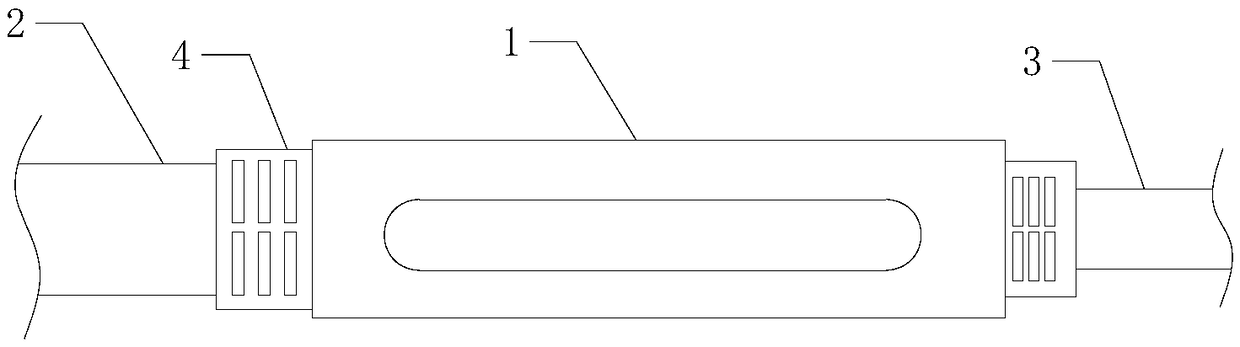

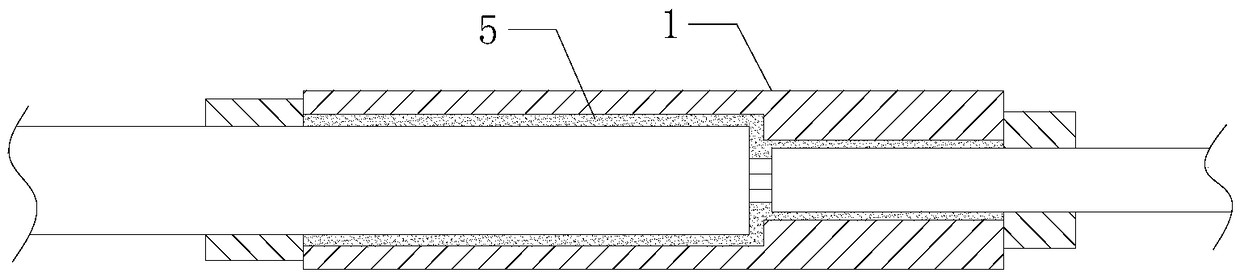

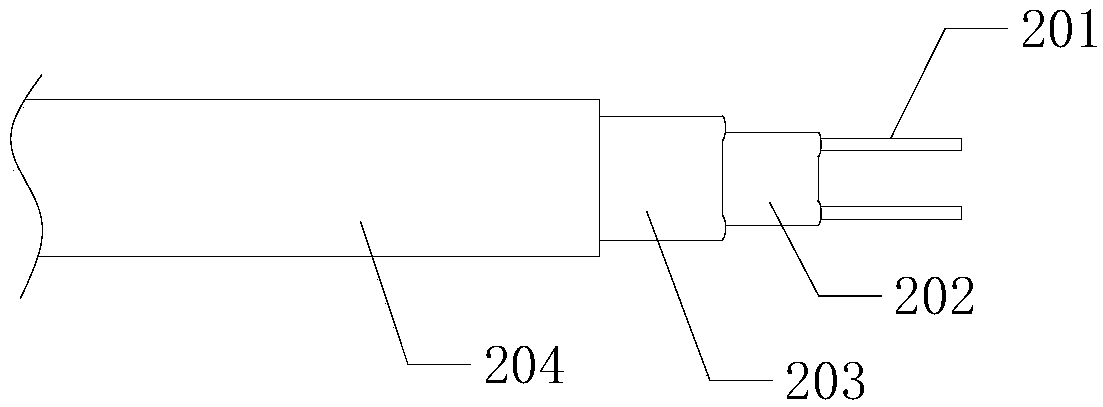

[0039] Such as figure 1 , figure 2 As shown, this embodiment provides a connection structure based on a PTC carbon heating cable, including a heating cable 2 , a connector 1 and an external cable 3 . Specifically, the connection structure includes a through hole inside the connector, and the through hole includes a first-section hole and a second-section hole, and a step is provided at the connection between the first-section hole and the second-section hole. ; One end of the heating cable extends into the first hole, one end of the external cable extends into the second hole, and the heating cable and the external cable are connected at the step; the inner cavity of the through hole is provided with Sealing layer, the inner surface of the sealing layer 5 is provided with a heat insulating layer.

[0040] The connecting head is molded by one-time compression molding of insulating material, and the connecting head is in the shape of a cylinder, and the through hole penetrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com