A device and working method for facilitating coating and shaping of semiconductor laser optical fiber

A laser and semiconductor technology, used in semiconductor lasers, lasers, phonon exciters, etc., can solve the problems of film peeling, poor shaping effect, affecting production efficiency, etc., to avoid fiber loss, avoid secondary transfer, improve The effect of shaping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

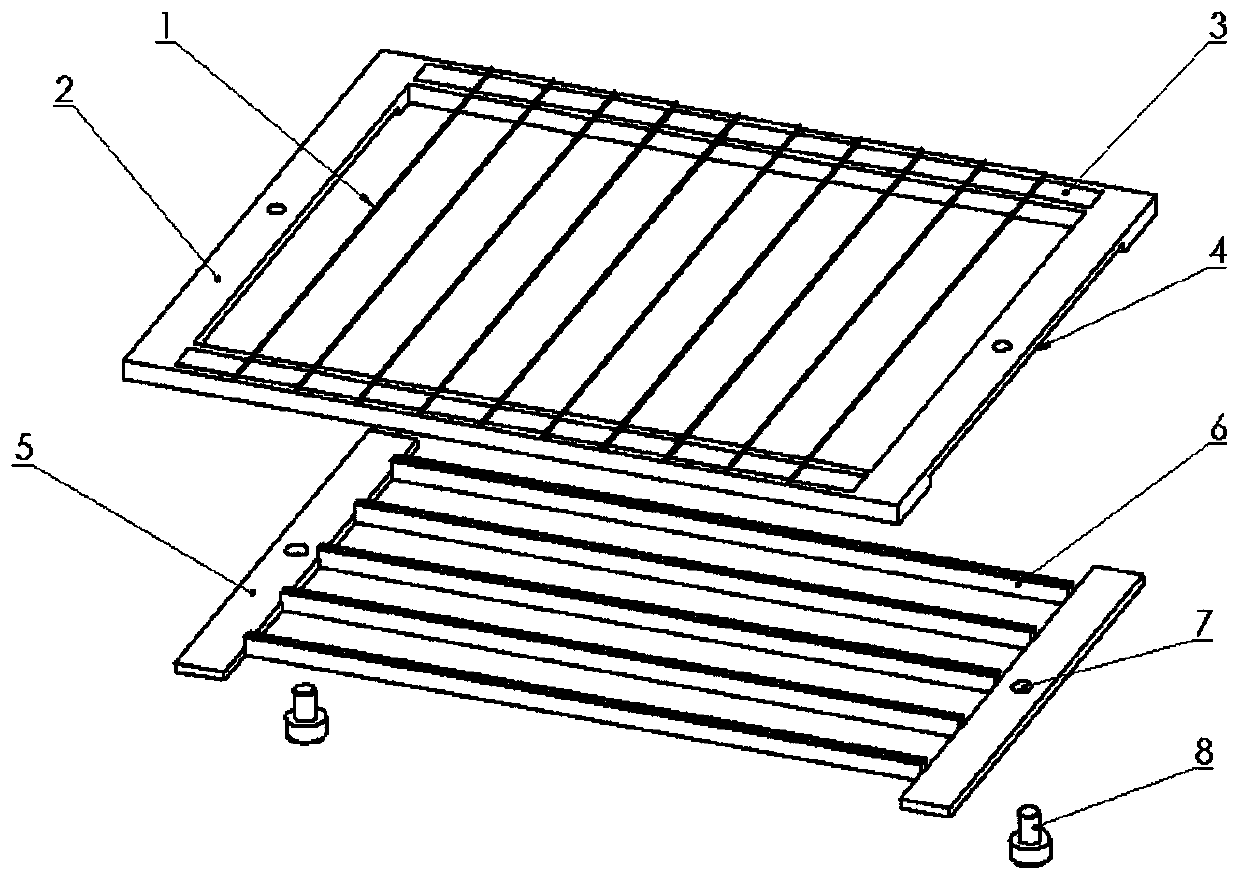

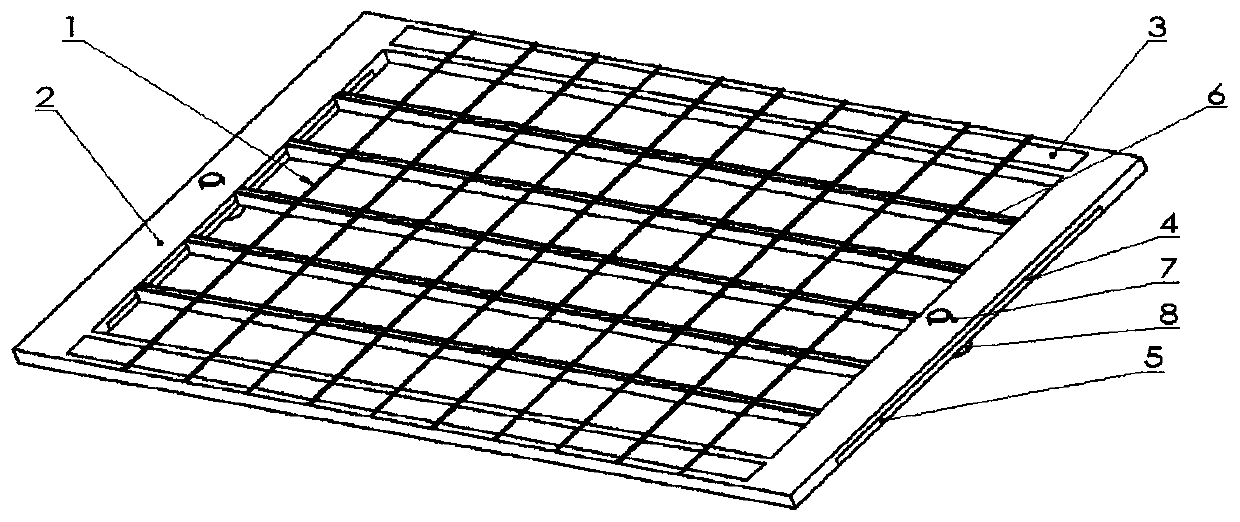

[0050] A device that facilitates coating and shaping of semiconductor laser fibers, such as figure 1 shown, including:

[0051] - fiber holder 2 for fixing fiber 1; and

[0052] - The isolation plate is located under the optical fiber fixing frame 2 and is connected with the optical fiber fixing frame 2 in a detachable manner;

[0053] -The isolation plate includes two side connection plates 5 and some parallel spacer strips 6 fixed between the two side connection plates 5, the spacer strips 6 and the optical fiber 1 fixed on the optical fiber holder 2 are basically perpendicular to each other, and are used for Support fiber 1 during shaping.

[0054] The materials of the optical fiber fixing frame 2 and the isolation plate are stainless steel with a hardness less than 187HB. Avoid high-temperature deformation of the optical fiber fixing frame 2 and the isolation plate in the coating machine.

[0055] The optical fiber fixing frame 2 is a hollow rectangular frame, and doub...

Embodiment 2

[0063] Utilize the method described in embodiment 1 to carry out the method for semiconductor laser fiber coating and shaping, concrete steps comprise:

[0064] (1) remove the coating on the surface of the optical fiber 1, and cut the optical fiber 1 into a short optical fiber having the same width as the optical fiber holder 2;

[0065] (2) Put the shortened optical fiber 1 in a glass container, soak it in acetone and ultrasonically clean it for half an hour;

[0066] (3) Glue double-sided heat-resistant adhesive tape 3 on the opposite sides of the upper surface of the optical fiber holder 2;

[0067] (4) The optical fiber 1 cleaned in step (2) is evenly adhered to the double-sided high-temperature-resistant adhesive tape 3 on the opposite sides of the upper surface of the optical fiber holder 2 in sequence, and the optical fiber 1 is parallel to the width direction of the optical fiber holder 2;

[0068] (5) Fix the optical fiber fixing frame 2 glued to the optical fiber 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com