Rubber plug conveying system used between rubber plug cleaning machine and filling and plugging machine

A rubber stopper cleaning machine and conveying system technology, applied in conveyors, cleaning methods using liquids, transportation and packaging, etc., can solve the problems of increasing the risk of secondary pollution of rubber stoppers and high costs, and avoid secondary transfer. , low cost, and the effect of reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

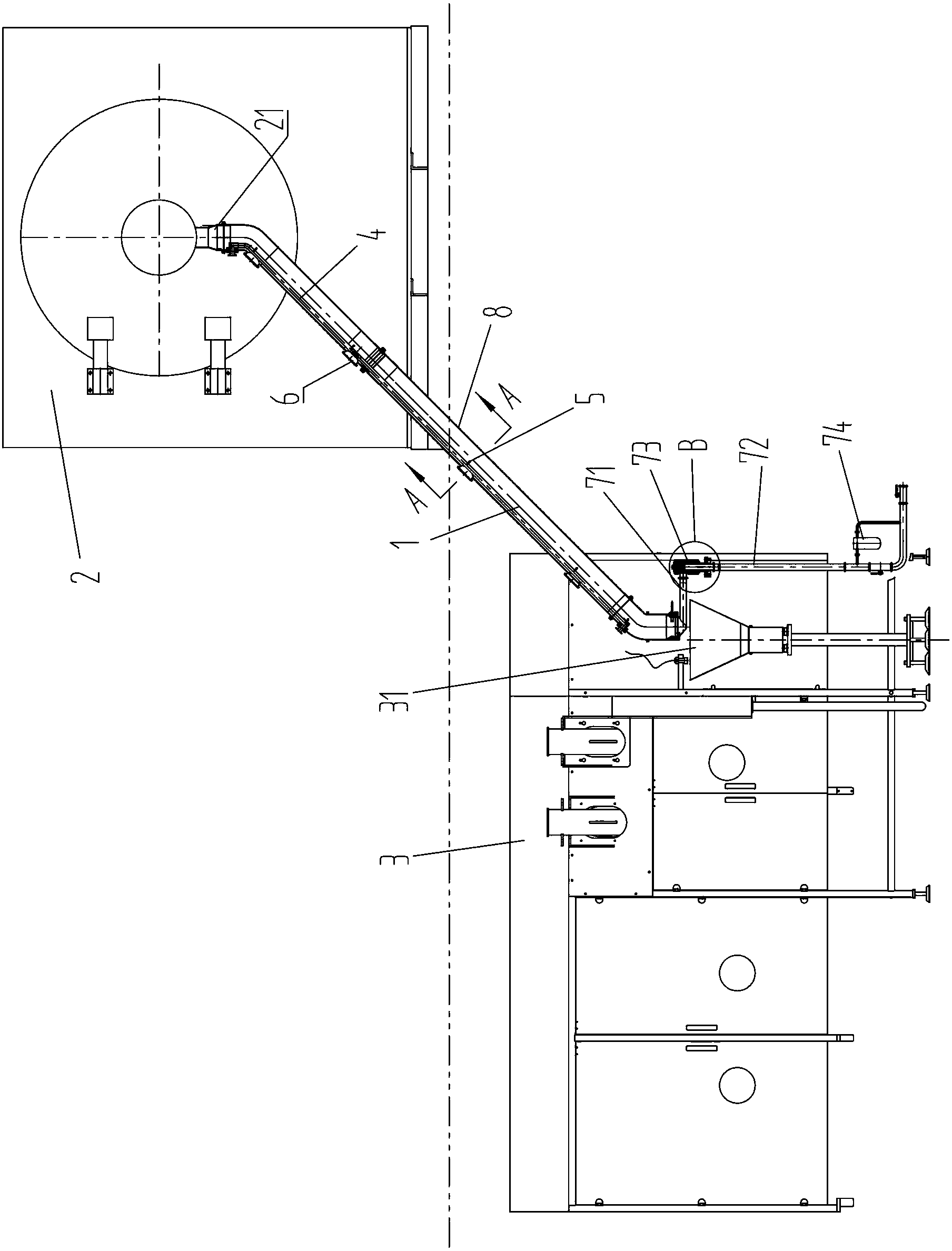

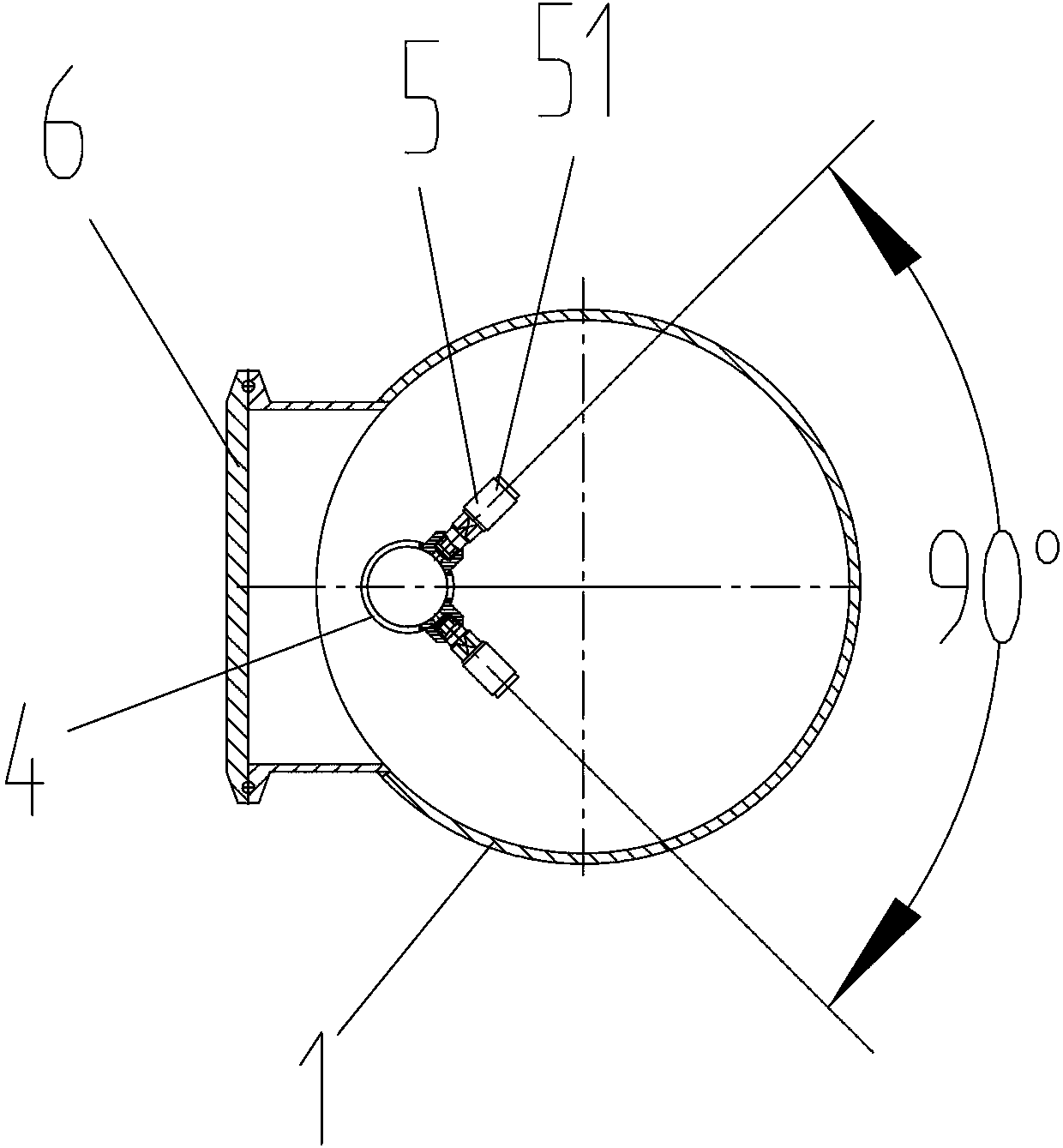

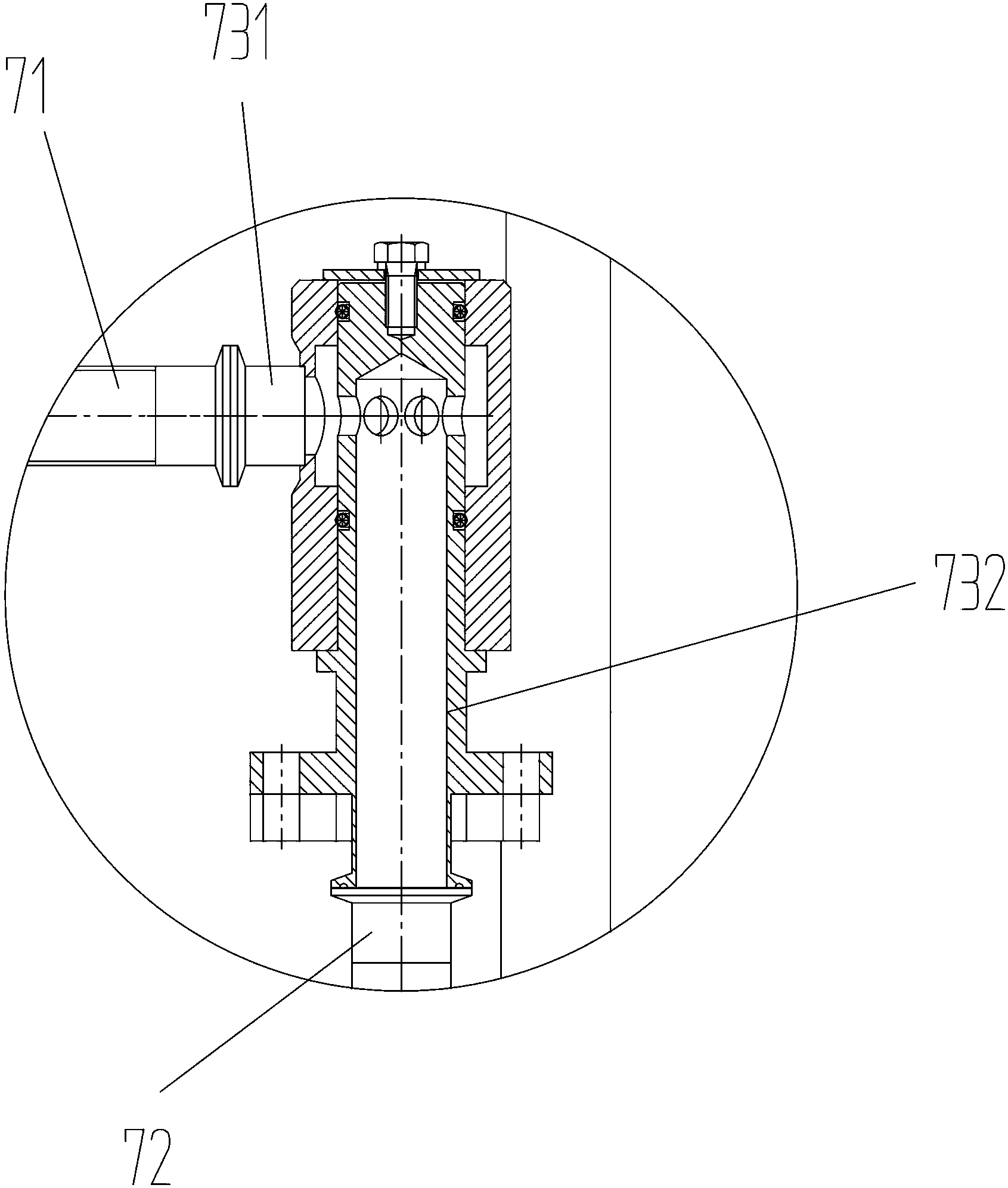

[0020] Such as figure 1 As shown, the rubber stopper conveying system used between the rubber stopper cleaning machine and the filling and corking machine of the present invention includes a rubber stopper conveying pipeline 1, an inlet end of the rubber stopper conveying pipeline 1 and a plug outlet 21 of the rubber stopper cleaning machine 2 Connected, the outlet end of the rubber stopper conveying pipeline 1 is connected with the plugging station 31 of the filling and corking machine 3, and the level of the rubber stopper conveying pipeline 1 gradually decreases from the inlet end to the outlet end. In practical application, the rubber stopper cleaning machine 2 can be placed above the filling and corking machine 3, so that a certain height difference is formed between the stopper outlet 21 of the rubber stopper cleaning machine 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com