Welding-free storage battery and production method thereof

A manufacturing method and battery technology, applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc., can solve the problems of leakage welding, battery plate falling off, loose and so on, and achieve the reduction of lead consumption, Facilitate production and processing, eliminate the effect of welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

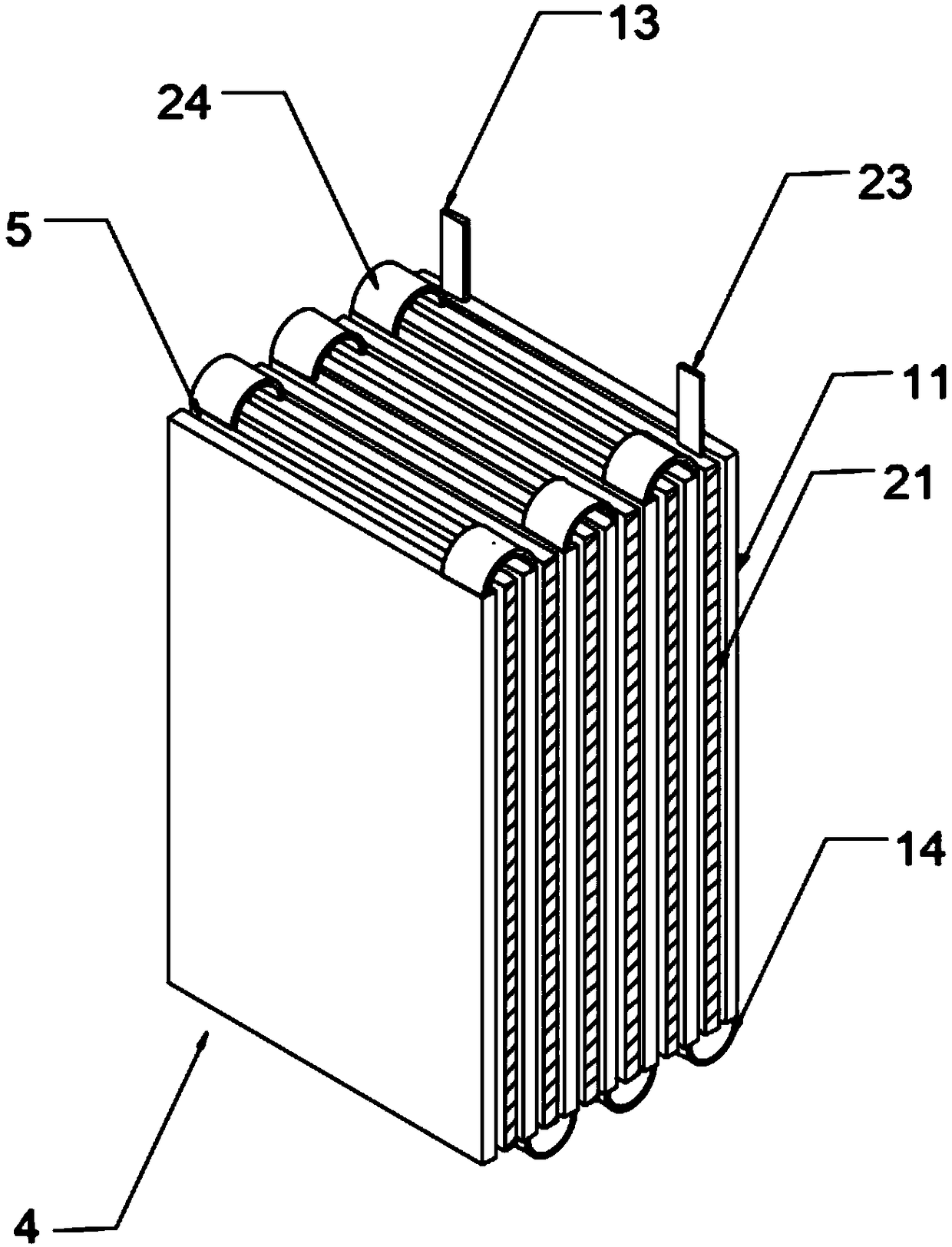

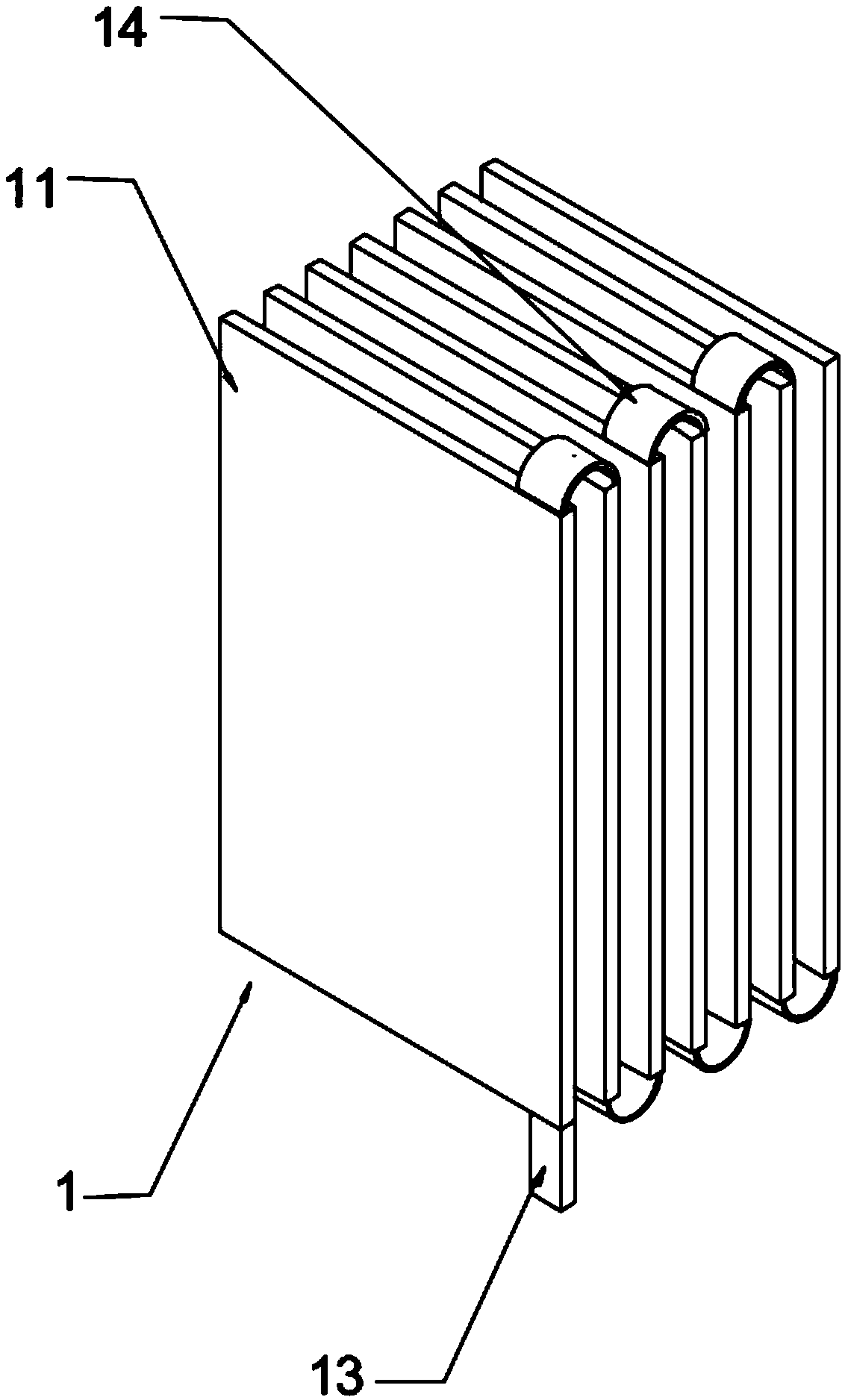

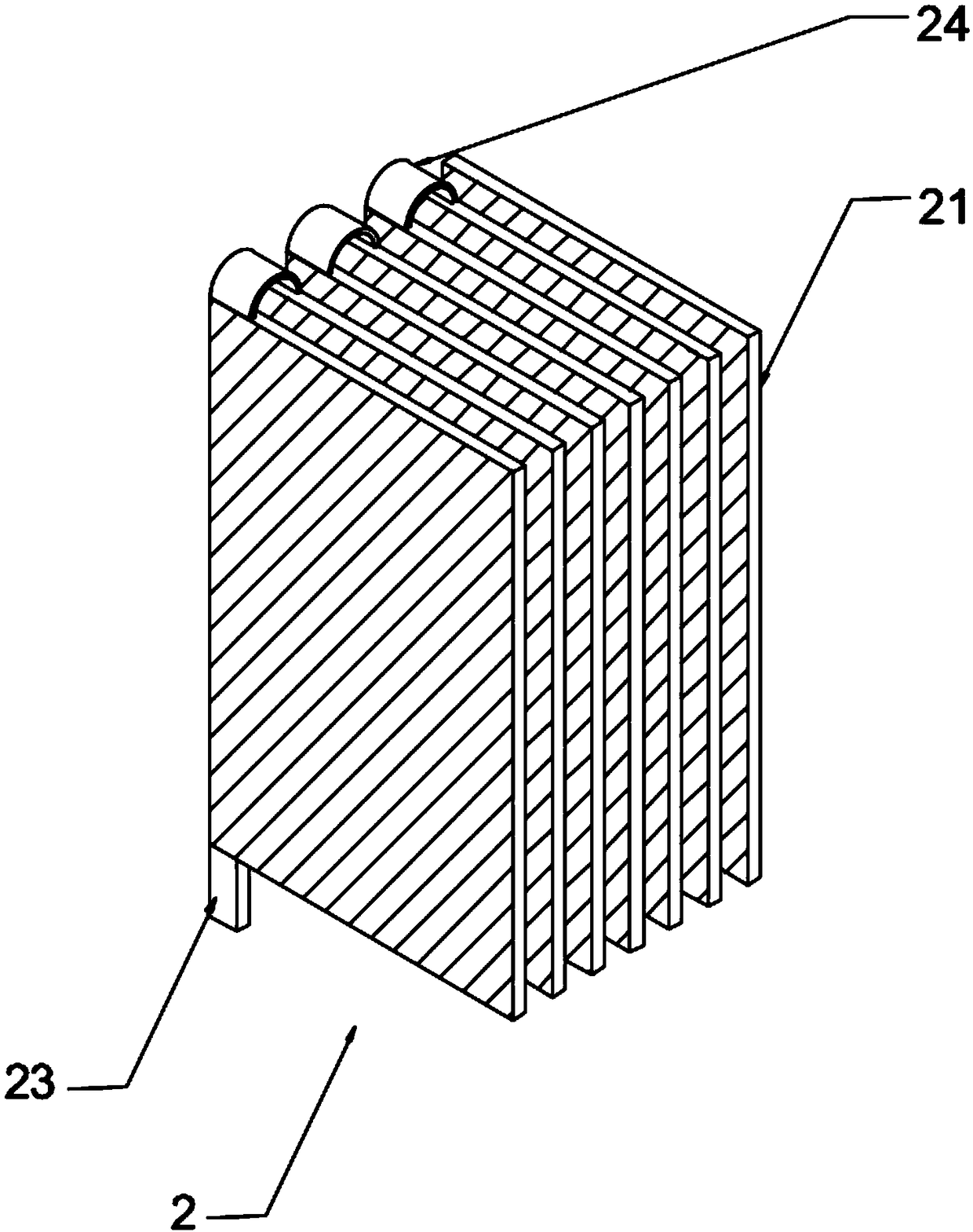

[0031] A kind of welding-free storage battery and its manufacturing method, such as figure 1 , figure 2 and image 3 As shown, the welding-free storage battery adopts the electrode group of the lead storage battery, which includes the continuous positive plate 1, the continuous negative plate 2, the cross-cell connecting piece 3, the continuous bipolar plate 4 and the separator 5, and the continuous The bipolar plate 4 is composed of a continuous positive plate 1 , a continuous negative plate 2 and a separator 5 that are plugged together.

[0032] Such as Figure 4 As shown, the continuous positive plate 1 includes several uniformly equidistantly arranged positive electrode coating plates 11 and several positive electrode annular connecting pieces 14, and the outer wall of each positive electrode coating plate 11 is provided with a positive electrode active material shell 12, and several positive electrode coating plates 11 The head of the first positive electrode coating ...

Embodiment 2

[0044] A kind of welding-free storage battery and its manufacturing method, such as figure 1 , figure 2 and image 3 As shown, the welding-free storage battery adopts the electrode group of the lead storage battery, which includes the continuous positive plate 1, the continuous negative plate 2, the cross-cell connecting piece 3, the continuous bipolar plate 4 and the separator 5, and the continuous The bipolar plate 4 is composed of a continuous positive plate 1 , a continuous negative plate 2 and a separator 5 that are plugged together.

[0045] Such as Figure 4 As shown, the continuous positive plate 1 includes several uniformly equidistantly arranged positive electrode coating plates 11 and several positive electrode annular connecting pieces 14, and the outer wall of each positive electrode coating plate 11 is provided with a positive electrode active material shell 12, and several positive electrode coating plates 11 The head of the first positive electrode coating ...

Embodiment 3

[0058] A kind of welding-free storage battery and its manufacturing method, such as figure 1 , figure 2 and image 3 As shown, the welding-free storage battery adopts the electrode group of the lead storage battery, which includes the continuous positive plate 1, the continuous negative plate 2, the cross-cell connecting piece 3, the continuous bipolar plate 4 and the separator 5, and the continuous The bipolar plate 4 is composed of a continuous positive plate 1 , a continuous negative plate 2 and a separator 5 that are plugged together.

[0059] Such as Figure 4 As shown, the continuous positive plate 1 includes several uniformly equidistantly arranged positive electrode coating plates 11 and several positive electrode annular connecting pieces 14, and the outer wall of each positive electrode coating plate 11 is provided with a positive electrode active material shell 12, and several positive electrode coating plates 11 The head of the first positive electrode coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com