Practical training teaching device of belt conveyor

A technology of belt conveyors and teaching devices, which is applied in transportation and packaging, simulation devices of space navigation conditions, simulators, etc., can solve the problems of learning new technologies, unsatisfactory practical teaching, and unable to allow students to occupy an area. small, improve teaching efficiency, and enhance the effect of training and practical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make those skilled in the art better understand the technical solution of the present invention, the technical solution of the present invention is clearly and completely described below in conjunction with the accompanying drawings of the present invention. Based on the embodiments in this application, those of ordinary skill in the art will Other similar embodiments obtained without creative work shall all fall within the scope of protection of this application.

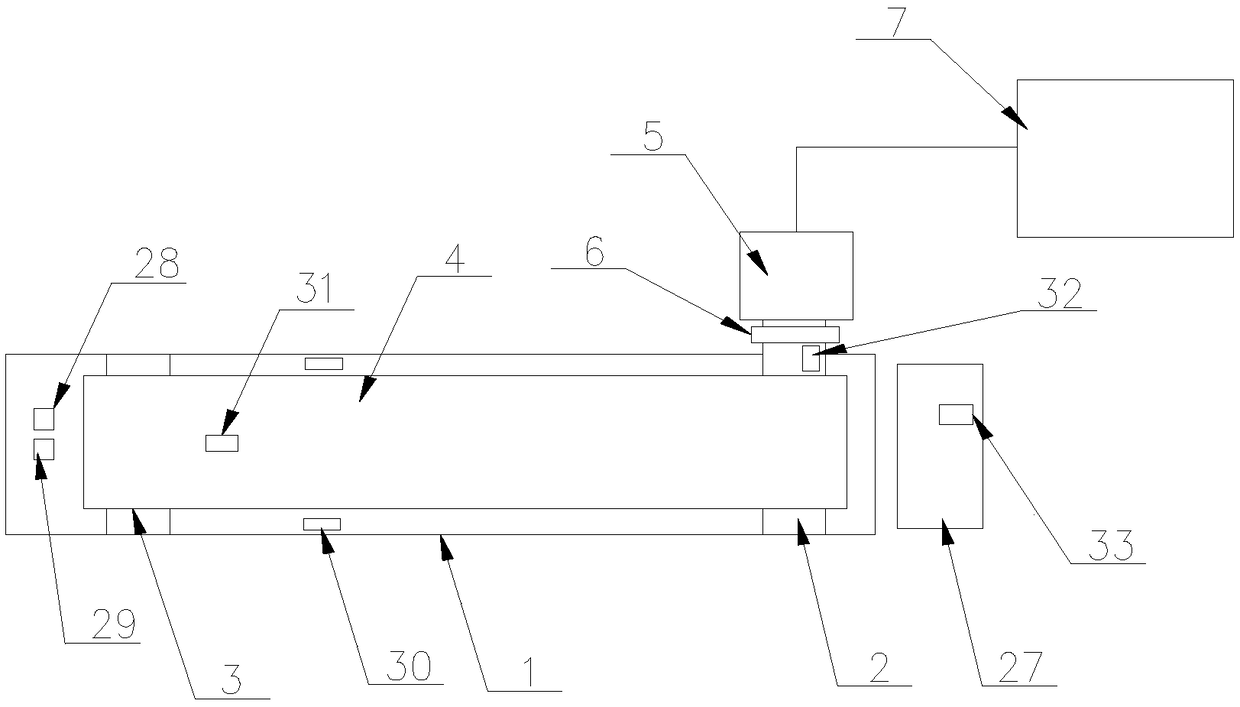

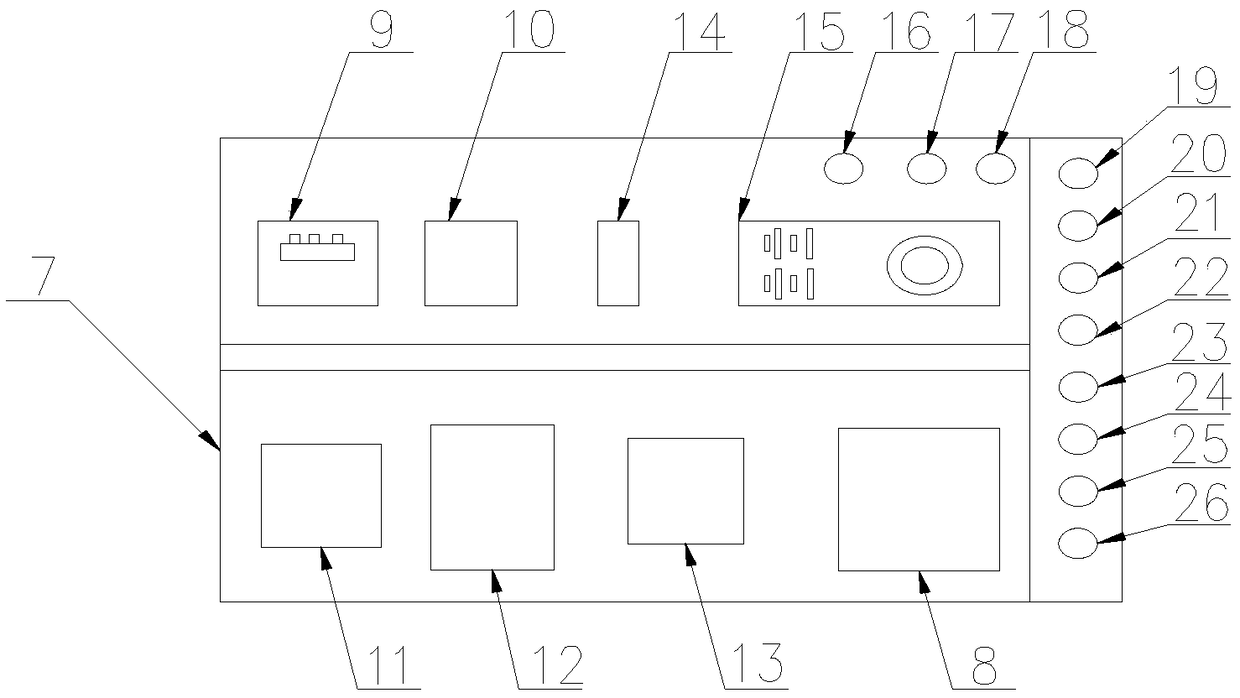

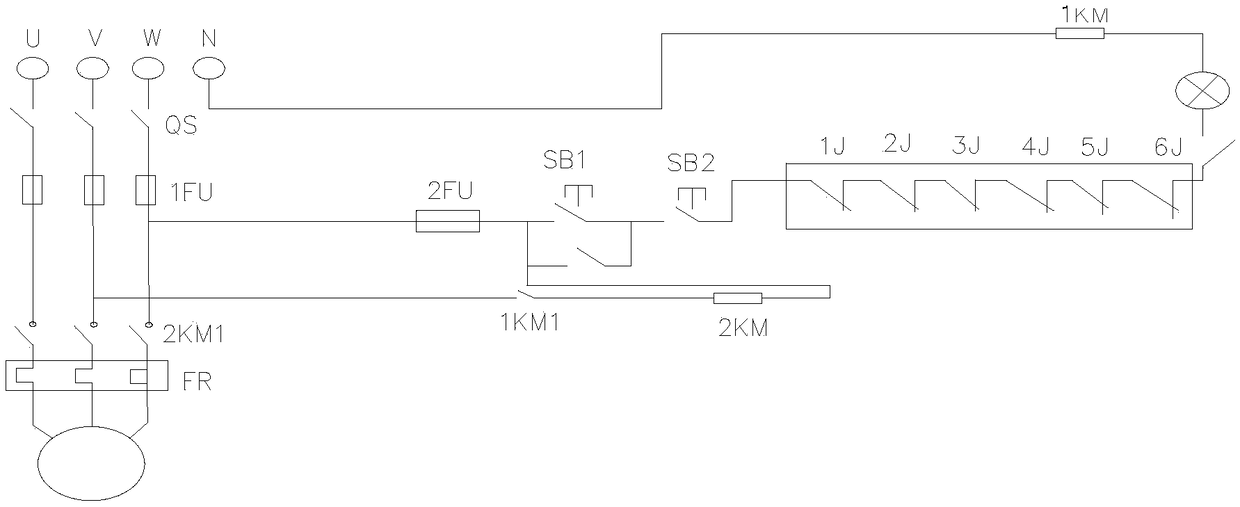

[0022] Such as figure 1 with figure 2 As shown, a belt conveyor practical training teaching device is provided in this embodiment, including a console 7, a belt conveyor body and a sensor assembly, wherein the belt conveyor includes a bracket 1, which is respectively arranged on two sides of the bracket 1. The driving wheel 2 and the driven wheel 3 at the end and the conveyor belt 4 arranged between the driving wheel 2 and the driven wheel 3, the driving wheel 2 is connected with a driving moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com