Laser interferometer mirror shape measurement method and photolithography device

A laser interferometer and topography measurement technology, applied in the field of semiconductors, can solve the problems such as the inability to completely eliminate the substrate topography error and inaccurate measurement results, and achieve the effect of reducing the substrate measurement area and shortening the time spent on calibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

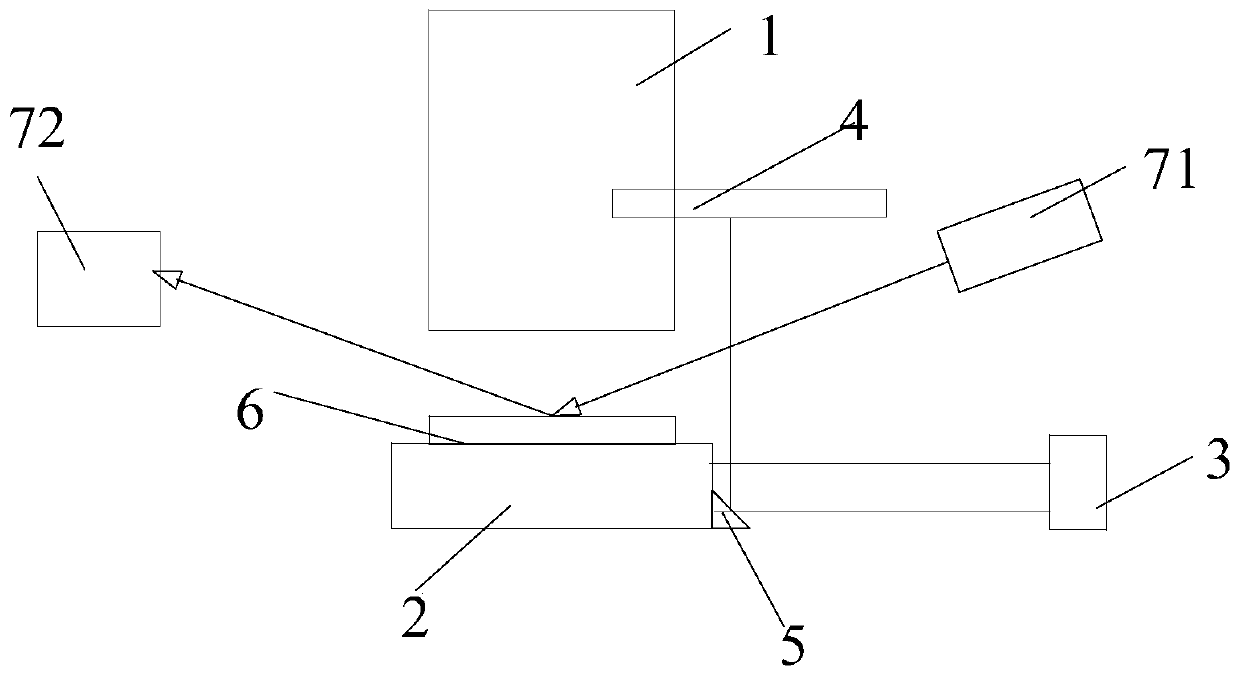

[0036] Please refer to figure 1 , the laser interferometer 3 is used to measure the vertical height and horizontal displacement of the workpiece table 2, and is generally arranged on one side of the workpiece table 2. Generally, the reflector is arranged on the workpiece table 2 and above the workpiece table 2. During the moving process of the workpiece table 2 The measurement light emitted by the laser interferometer is reflected by the mirror and returns to the laser interferometer 3, so as to calculate the real-time vertical height of the workpiece table 2. The laser interferometer 3 is equipped with two reflectors, one is a strip reflector 4 fixed on one side of the projection objective lens 1, and the other is an oblique reflector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com