Heat sink with graphene coating

A heat sink and graphene technology, applied in optics, instruments, projection devices, etc., can solve the problems of low thermal radiation coefficient of metal surface, difficulty in dissipating heat from metal surface, limiting the use effect and service life of electrical devices, etc., to achieve The effect of compact structure, improved heat dissipation effect, and reasonable overall structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

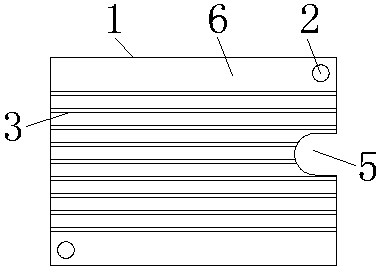

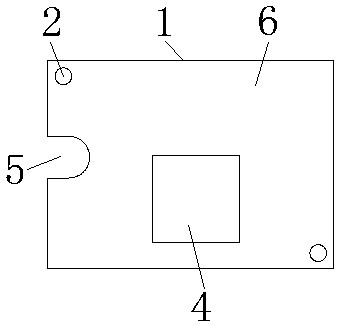

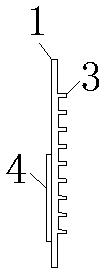

[0015] like figure 1 , figure 2 and image 3 As shown, a heat sink with a graphene coating according to the present invention includes a heat sink body 1, and a fixed connection hole 2 is provided on the front of the heat sink body 1, and between the fixed connection holes 2 The front of the radiator body 1 is evenly provided with cooling fins 3, the back of the radiator body 1 is provided with a heat dissipation contact boss 4, and a U-shaped opening 5 is arranged in the middle of one side of the radiator body 1. The radiator Body 1, heat dissipation fin 3 and heat dissipation contact boss 4 are integrally formed, and a graphene coating 6 is provided on the surface of the heat sink body 1, heat dissipation fin 3 and heat dissipation contact boss 4, and the thickness of the heat dissipation contact boss 4 is 1. The ratio of the thickness of the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com