OC-type fore-shaft steel pipe pile structure, steel pipe pile cofferdam and self-compaction water stop method

A steel pipe pile and lock-type technology, which is applied in the direction of infrastructure engineering, erection/assembly of bridges, bridges, etc., can solve the problem of poor mixing and fluidity of water-stop materials, hidden dangers of on-site construction safety, and poor water-stop effect Ideal and other issues, to achieve the effect of easy on-site operation, good fluidity, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

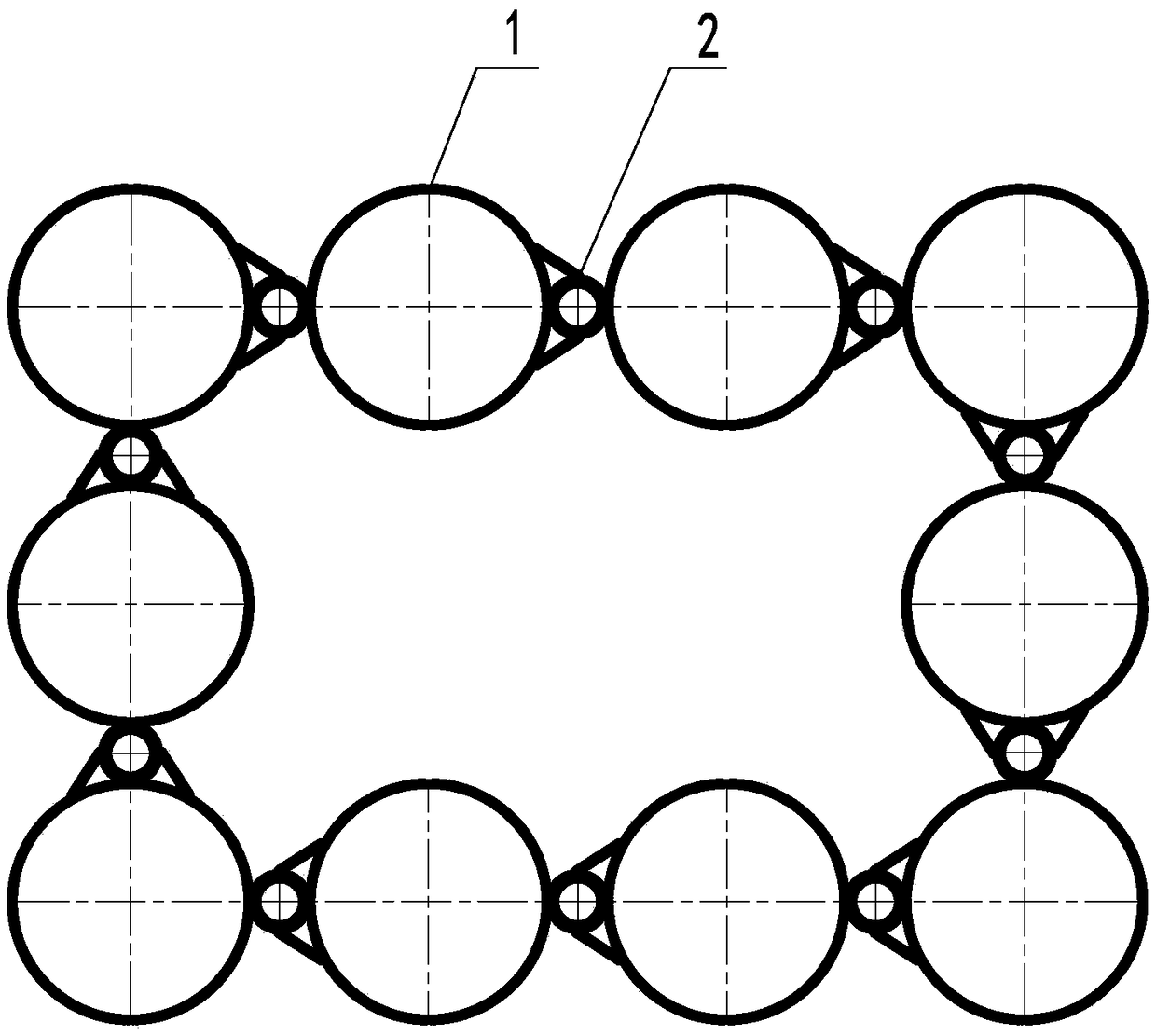

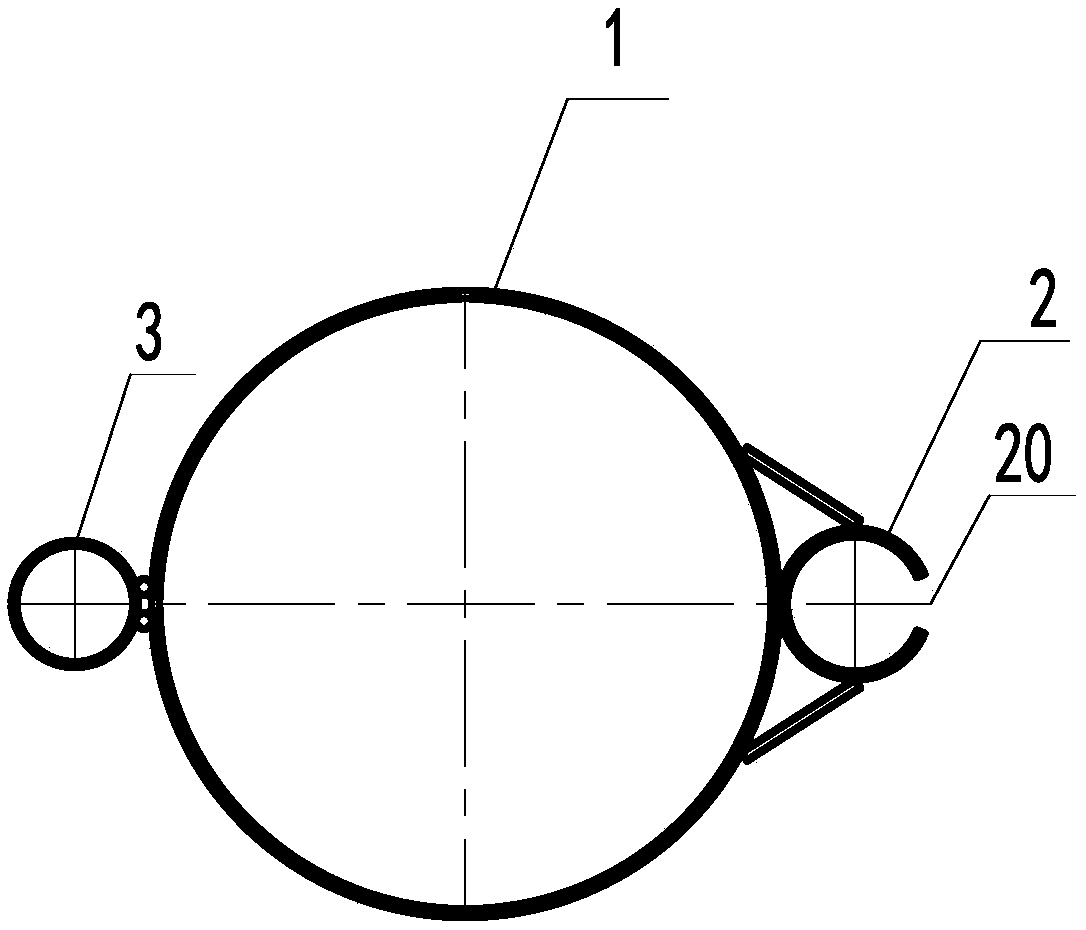

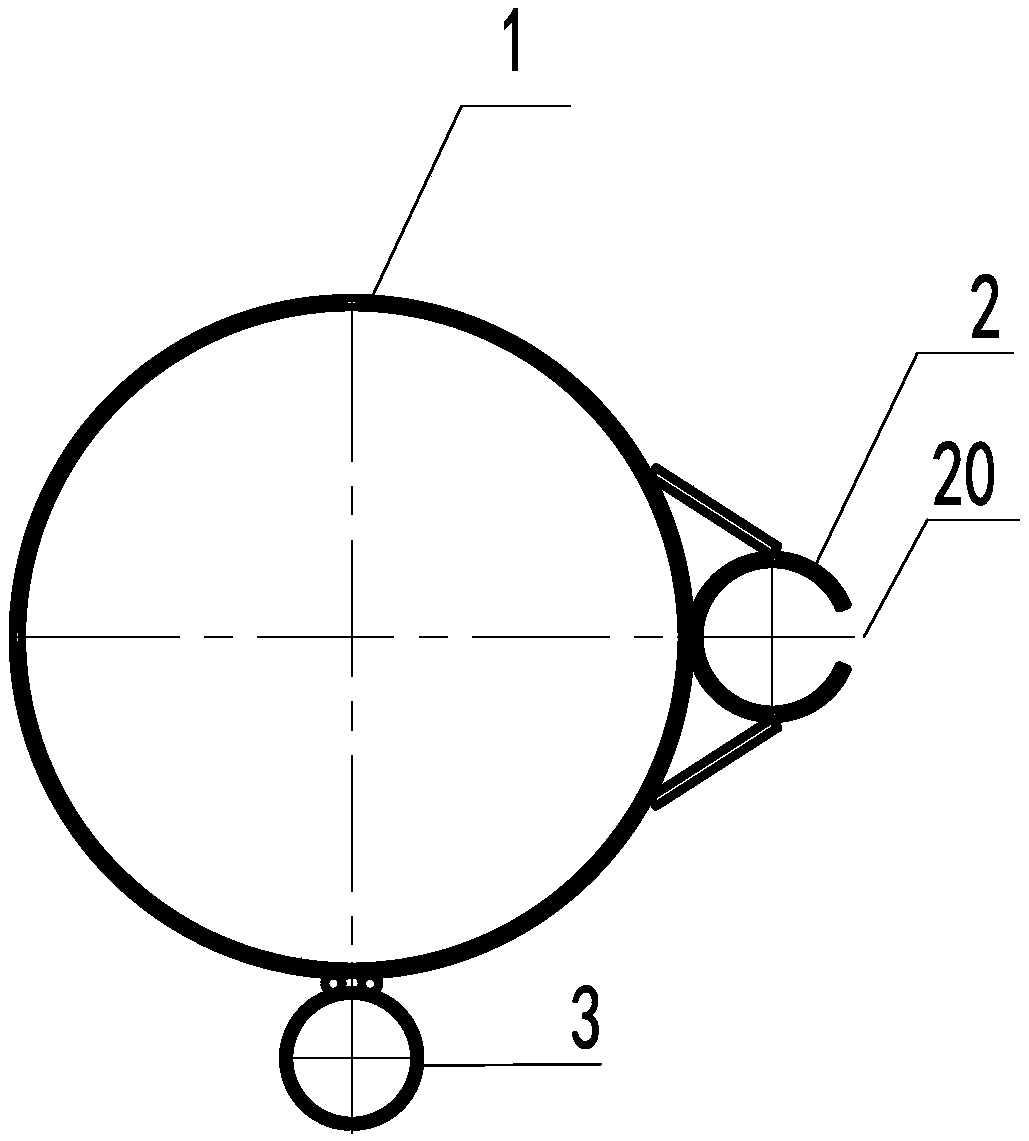

[0029] see Figure 1 to Figure 3 As shown, the embodiment of the present invention provides an OC-type lock-type steel pipe pile structure, which includes a large-diameter steel pipe 1, and also includes a C-shaped small-diameter steel pipe 2 coaxial with the large-diameter steel pipe 1 and an O-shaped small-diameter steel pipe 3. The C-type small-diameter steel pipe 2 and the O-type small-diameter steel pipe 3 are arranged at intervals on the outer circumference of the large-diameter steel pipe 1; among them, the C-type small-diameter steel pipe 2 is provided with a gap 20 along the axial direction; A notch 30 is provided, and the O-shaped small-diameter steel pipe 3 is used for fitting with the C-shaped small-diameter steel pipe 2 of another adjacent large-diameter steel pipe 1 .

[0030] In the OC type lock type steel pipe pile structure p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com