Auxiliary agent for dyeing superfine fiber synthetic leather with high color fastness and preparation method thereof

A technology of ultra-fine fiber and high color fastness, which is applied in the fields of dyeing, textiles and papermaking, etc. It can solve problems such as difficult to meet dyeing requirements, exposed bottom, and difficult dyeing of dyes, so as to improve dyeing efficiency, ensure tightness, The effect of increasing the spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a preparation method of an auxiliary agent for dyeing superfine fiber synthetic leather with high color fastness, comprising the following steps:

[0024] (1) Carry out acidification treatment to carbon nanotubes, then add sepiolite fiber and dispersant, ultrasonically disperse for 20-30min, and obtain modified sepiolite fiber by centrifugal filtration;

[0025] (2) add acidic solution in chitosan, the chitosan solution that acidification is obtained after stirring treatment, then mixes with the modified sepiolite fiber in step (1);

[0026] Wherein, the acidified chitosan solution accounts for 5-10% of the total weight of the mixture;

[0027] (3) In the mixture system of step (2), dropwise add a mass fraction of 5% NaOH solution in the process of stirring, adjust the pH value of the mixture system to be 8-12, and continue stirring for 30-60min to obtain the described Auxiliary for dyeing microfiber synthetic leather.

[0028] In the present in...

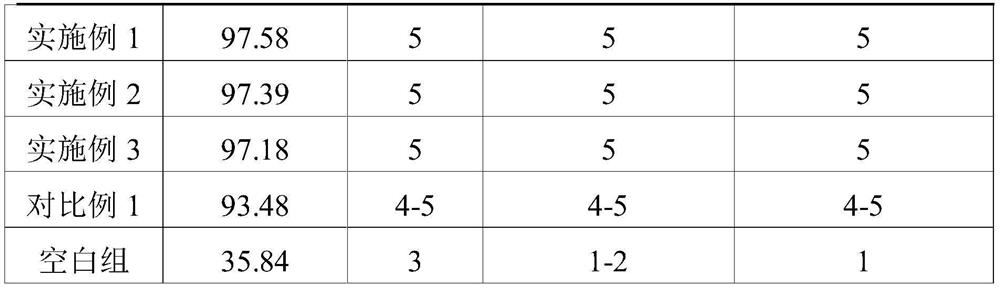

Embodiment 1

[0044] A preparation method of an auxiliary agent for dyeing superfine fiber synthetic leather with high color fastness, comprising the following steps:

[0045] (1) adding a sulfuric acid solution with a concentration of 40% to 500 g of carbon nanotubes so that the pH of the solution is 4.8, and stirring slowly for 50 min;

[0046] Then add 2500g sepiolite fiber and 9g sodium hexametaphosphate, ultrasonically disperse for 20min, and centrifugally filter to obtain modified sepiolite fiber;

[0047] (2) get the chitosan that viscosity is 400cps, add massfraction in chitosan and be the hydrochloric acid solution of 5%, obtain the chitosan solution of acidification after the stirring process, then with the modified seafoam in step (1) stone fiber mix;

[0048] Wherein, the chitosan solution of acidification accounts for 8% of mixture gross weight;

[0049] (3) in the mixture system of step (2) dropwise in the mixture system of step (2) is the NaOH solution of 5% by mass fractio...

Embodiment 2

[0054] A preparation method of an auxiliary agent for dyeing superfine fiber synthetic leather with high color fastness, comprising the following steps:

[0055] (1) adding a sulfuric acid solution with a concentration of 50% to 500 g of carbon nanotubes so that the pH of the solution is 5.0, and stirring slowly for 60 min;

[0056] Then add 1750g sepiolite fiber and 9g sodium hexametaphosphate, ultrasonically disperse for 20min, and centrifugally filter to obtain modified sepiolite fiber;

[0057] (2) get the chitosan that viscosity is 400cps, add massfraction in chitosan and be the hydrochloric acid solution of 5%, obtain the chitosan solution of acidification after the stirring process, then with the modified seafoam in step (1) stone fiber mix;

[0058] Wherein, the chitosan solution of acidification accounts for 5% of mixture gross weight;

[0059] (3) in the mixture system of step (2) dropwise in the mixture system of step (2) be the NaOH solution of 5% by mass fractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com