Preparation method of vilazodone hydrochloride type IV crystal

The technology of vilazodone hydrochloride and vilazodone is applied in the field of preparation of type IV crystal of vilazodone hydrochloride, which can solve the problems of increased production cost, large amount of isopropanol, and poor refining effect , to avoid the effect of oxidative degradation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

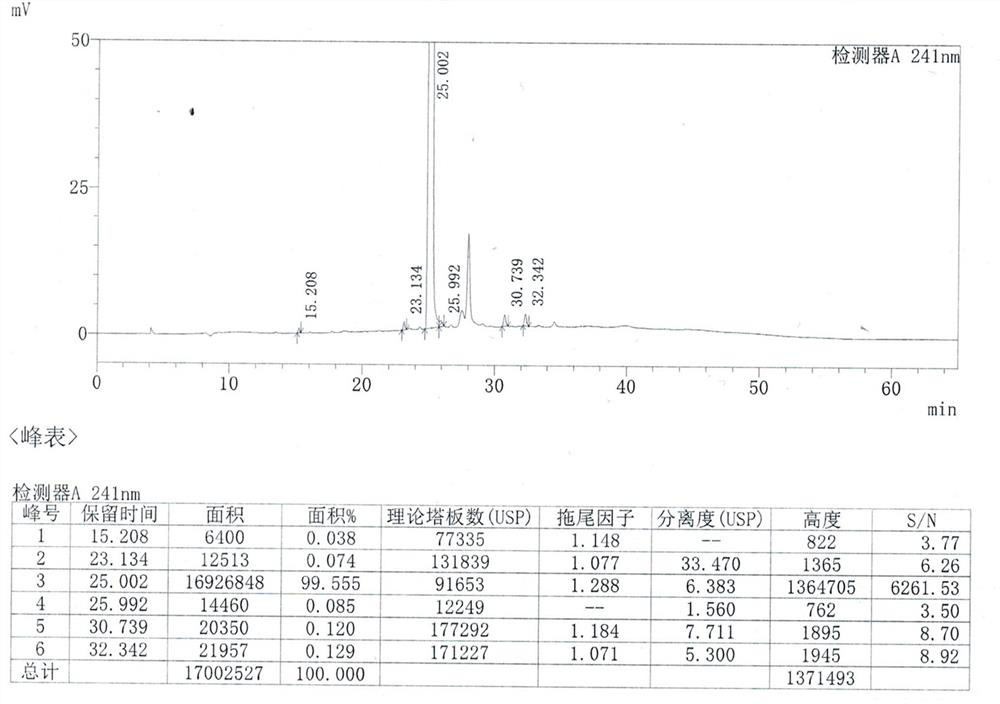

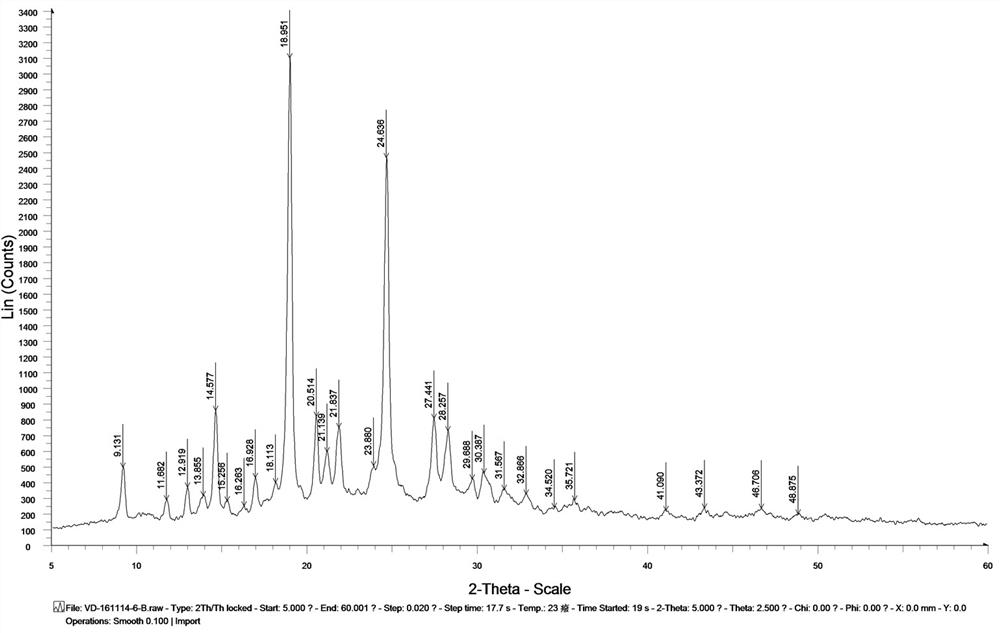

Embodiment 1

[0024] Put the crude vilazodone (10.00g) and sodium metabisulfite (0.05g) in isopropanol (40mL) and DMSO (10ml), stir and heat to 80°C~85°C to dissolve it. After dissolving, add activated carbon (0.5g) and stir at 80°C to 85°C for 30 minutes. After stirring, filter out the activated carbon while it is hot, and rinse the filter cake with isopropanol ketone (10mL). After the filtrate was heated again to 40~50°C, add isopropanol hydrochloride (according to the 1.1eq calculation of the crude product of vilazodone), after the addition was completed, the temperature was raised to 80°C~85°C, and stirred at 80°C~85°C for 3 hours, then lower the temperature to 20°C~30°C, and stir at 20°C~30°C for 1 hour. After suction filtration, the filter cake was rinsed with isopropanol (10 mL), and dried at 70-80°C for 6 hours to obtain 10.32 g of off-white powder crystals (type IV crystals), with a yield of 95.3%.

Embodiment 2

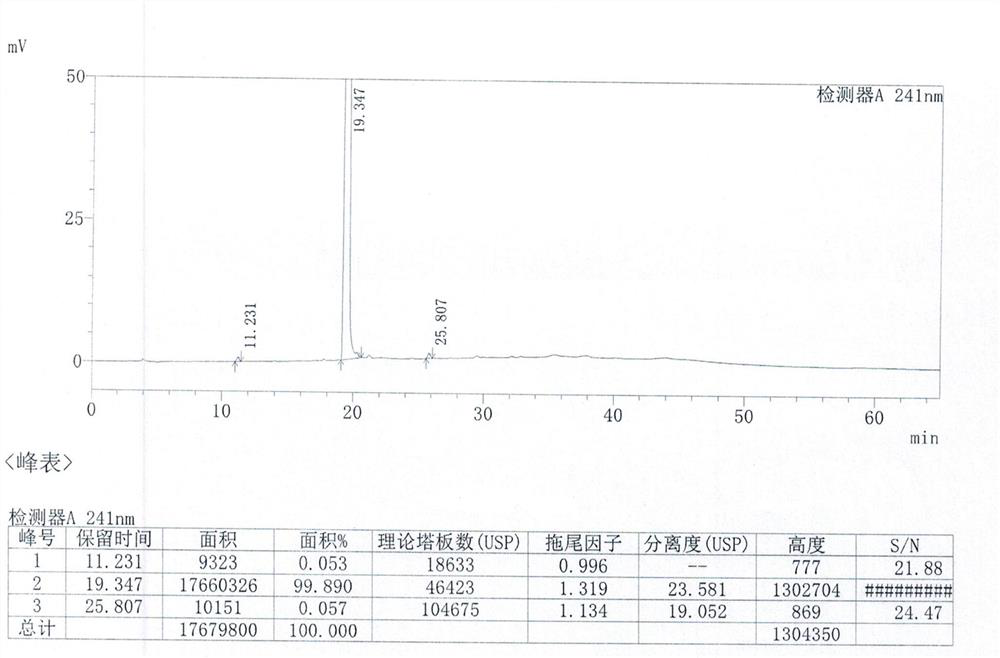

[0026] Put the crude vilazodone (3.50g) and sodium metabisulfite (0.02g) in n-butanol (30mL) and DMSO (5mL), stir and heat to 100°C~110°C to dissolve. After dissolving, slowly lower the temperature to 80°C~90°C, add isopropanol hydrochloride (calculated according to 1.1eq of crude vilazodone), and stir for 2 hours at the same temperature. After suction filtration, the filter cake was rinsed with n-butanol (10 mL), and dried at 70°C to 40°C for 4 hours to obtain 3.56 g of off-white powder crystals (type IV crystals), with a yield of 94.1%.

Embodiment 3

[0028] Put the crude vilazodone (10.00g) and sodium bisulfite (0.05g) in anisole (70mL) and DMF (10mL), stir and heat to 100°C~110°C to dissolve. After dissolving, add isopropanol hydrochloride at 80~90°C. After the addition was complete, the mixture was stirred at the same temperature for 4 hours. After suction filtration, the filter cake was rinsed with anisole (10 mL), and dried at 70-80°C for 6 hours to obtain 10.27 g of off-white powder crystals (type IV crystals), with a yield of 93.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com