Stabilizer for preventing granule floating in stirring process of glass bead heat-preservation concrete

A technology of thermal insulation concrete and vitrified microbeads, which is applied in the field of building materials, can solve the problems of reducing concrete strength and durability, unfavorable forming and strength development, and affecting concrete construction performance, so as to maintain long-term stability, simple technology, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The formula of the stabilizer of the present invention is: 2-5 parts of thickener, 25-55 parts of water reducer, 2-3 parts of air-entraining agent, 300-400 parts of nano kaolin, and 350-400 parts of fly ash.

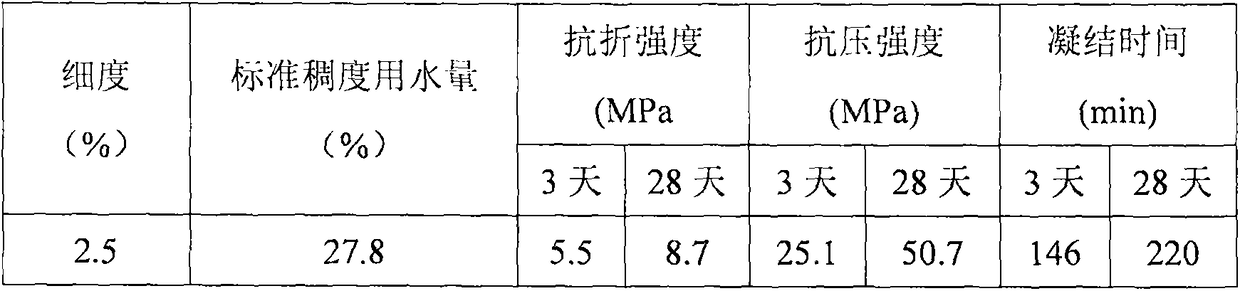

[0025] (1) Cement, Jiangnan Onoda PO42.5 grade, its properties are as follows:

[0026]

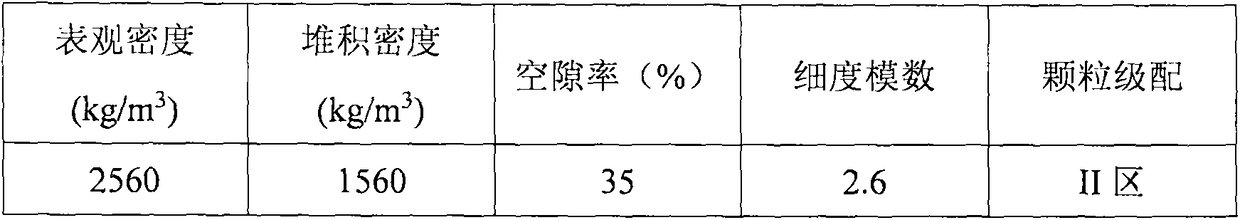

[0027] (2) Sand, using ordinary river sand, the performance is as follows:

[0028]

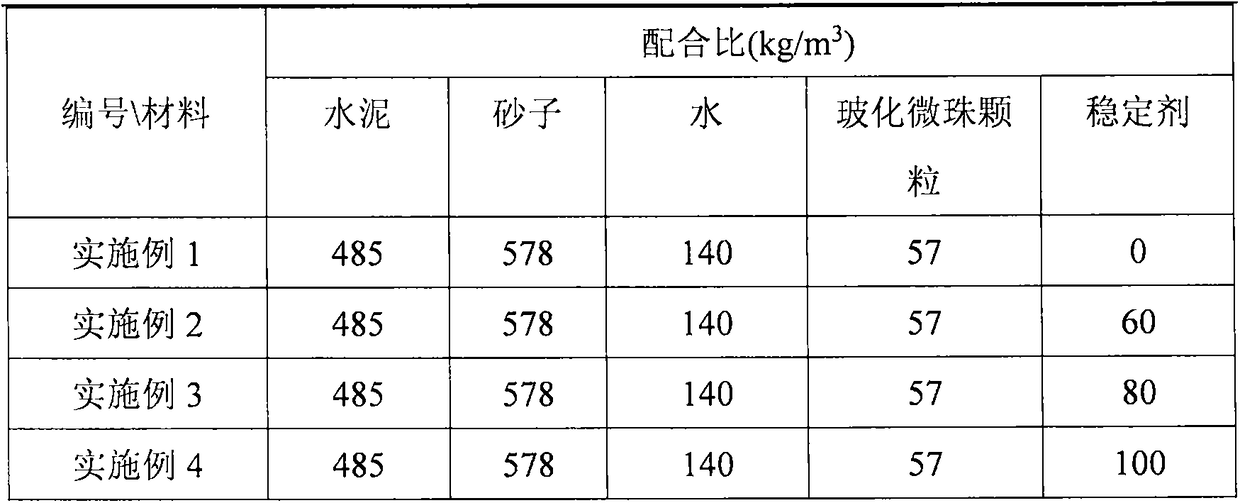

[0029] Prepare the stirred vitrified microbead insulation coagulation according to the following mass ratio. The formula of each coagulation sample is the same, only the dosage of the stabilizer is different, as shown in the following table:

[0030]

[0031] According to the above mixing ratio, the effect of different stabilizer dosages on the uniformity of vitrified microbeads was studied, and the results are shown in the table below.

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com