Cuboidal passive novel separating equipment

A technology of separation equipment and cuboid, which is applied in the field of cuboid passive new separation equipment, can solve the problems of limited use of equipment, inability to use, high energy consumption, etc., and achieve the effects of convenient installation and maintenance, improved online monitoring, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

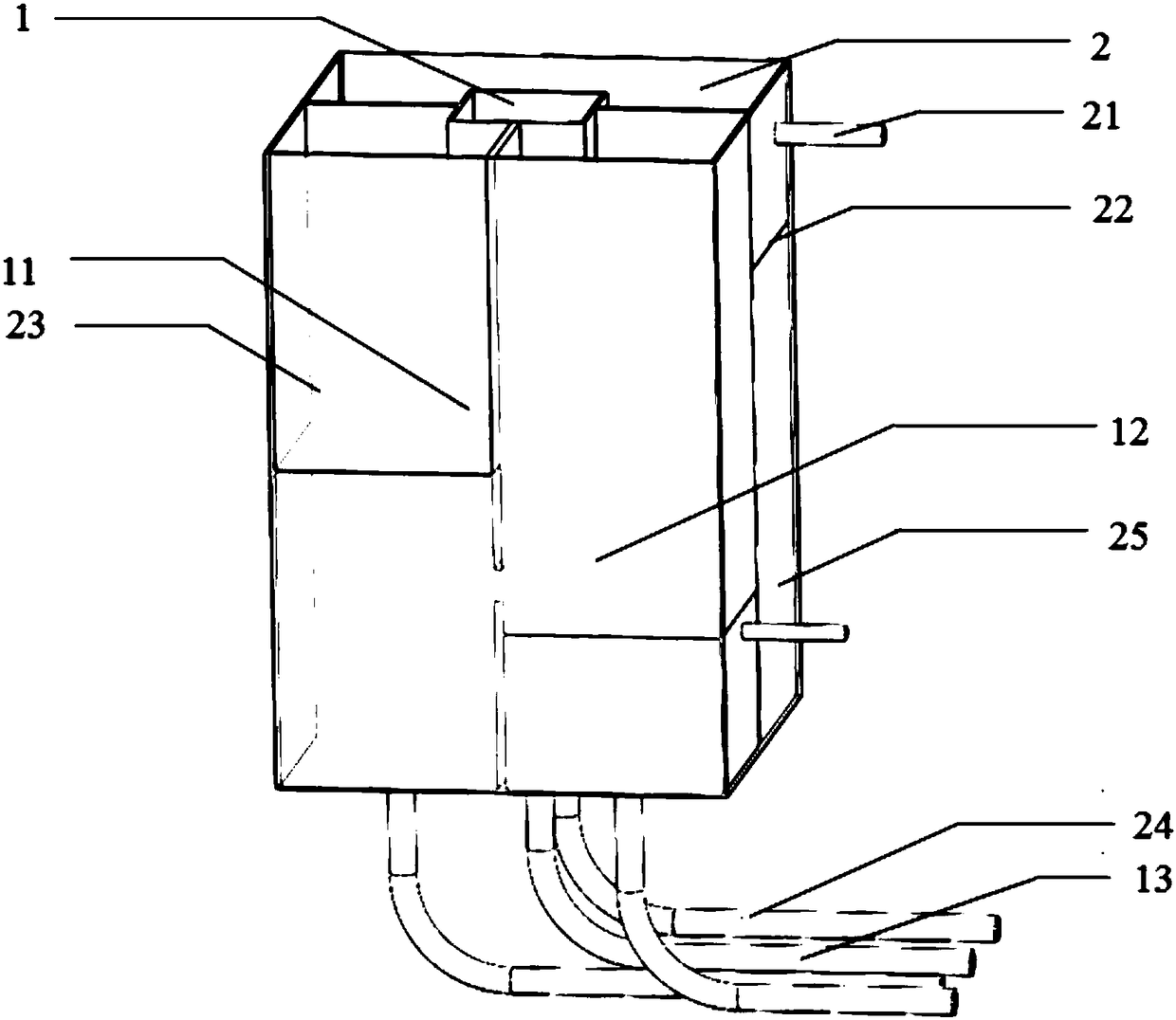

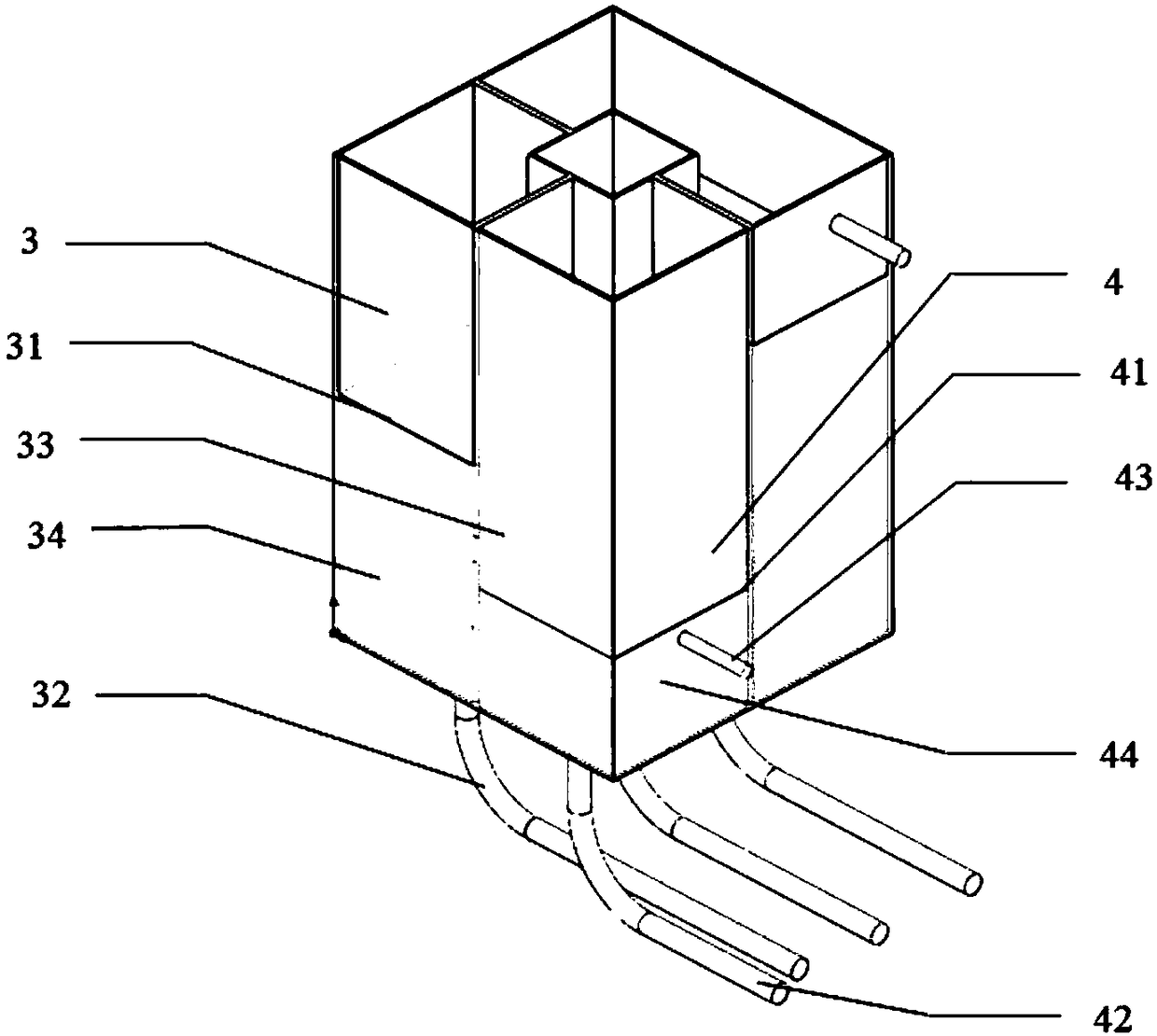

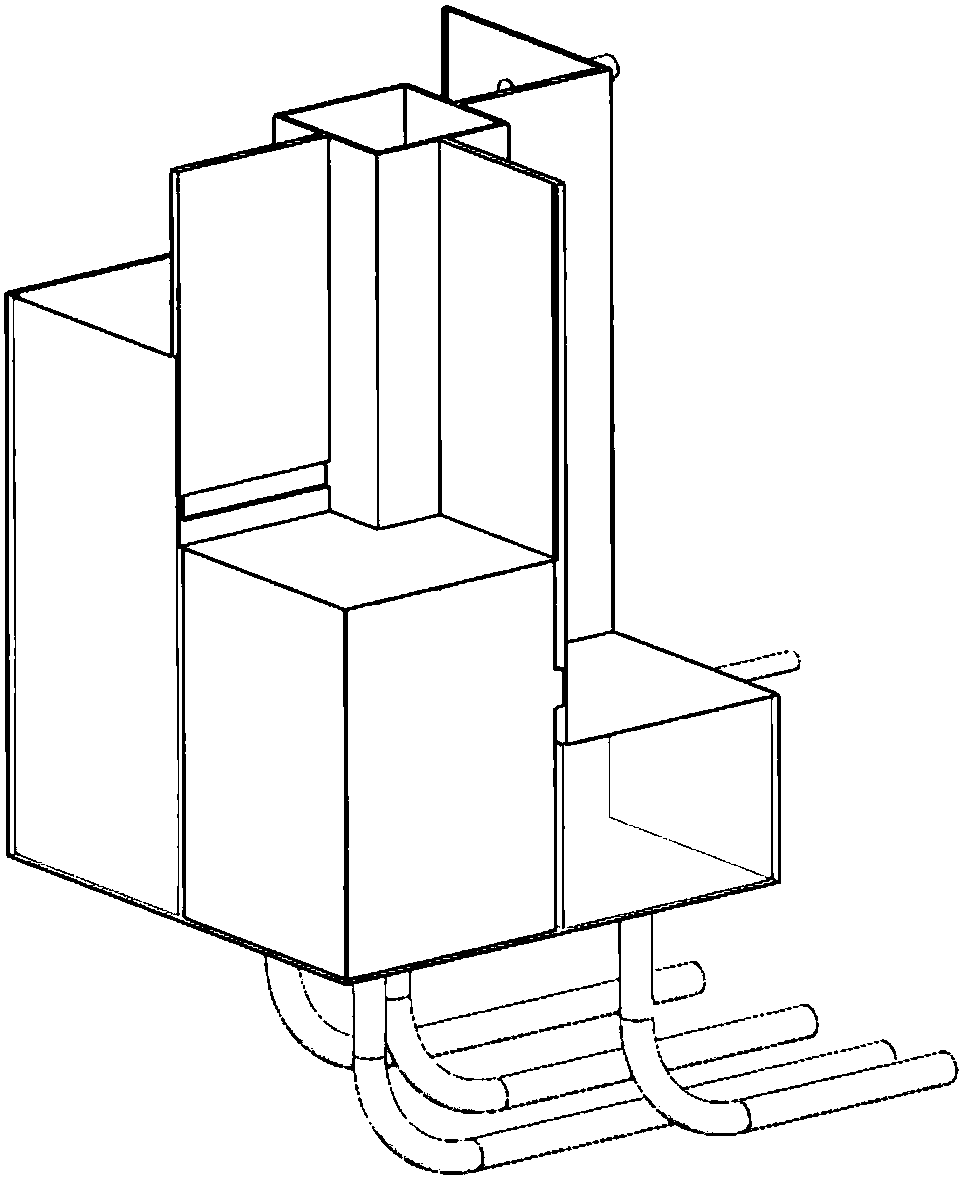

[0024] Such as figure 1 , figure 2 and image 3 Shown: the mixture enters the device through the water inlet (21). The mixture may include small solid particles, water and one or more other liquids that are immiscible with water. The mixture enters the first stage filter (2). The first-stage filtering device (2) mainly realizes the purpose of slag removal, that is, the removal of solid particles, mainly by means of the solid filter screen (22). The slag-removed mixture enters the second-stage filter device (3) through the first liquid flow hole (23) between the first-stage filter device (2) and the second-stage filter device (3). The second-stage filter device (3) mainly separates liquids from liquids, and separates water from water-insoluble liquids. The second-stage filter device (3) realizes liquid-liquid separation, mainly relying on the new first separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com