Screw compressor used for kitchen waste dewatering

A technology for screw compressors and kitchen waste, which can be applied to stamping machines, presses, manufacturing tools, etc., and can solve the problem of high water content in waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

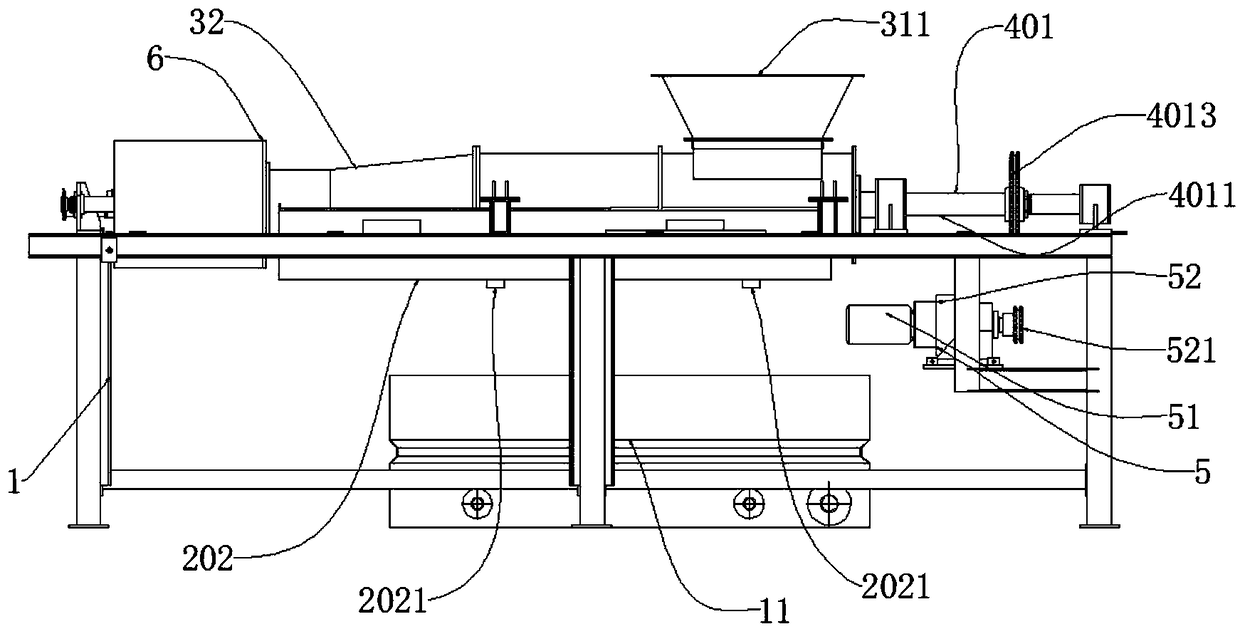

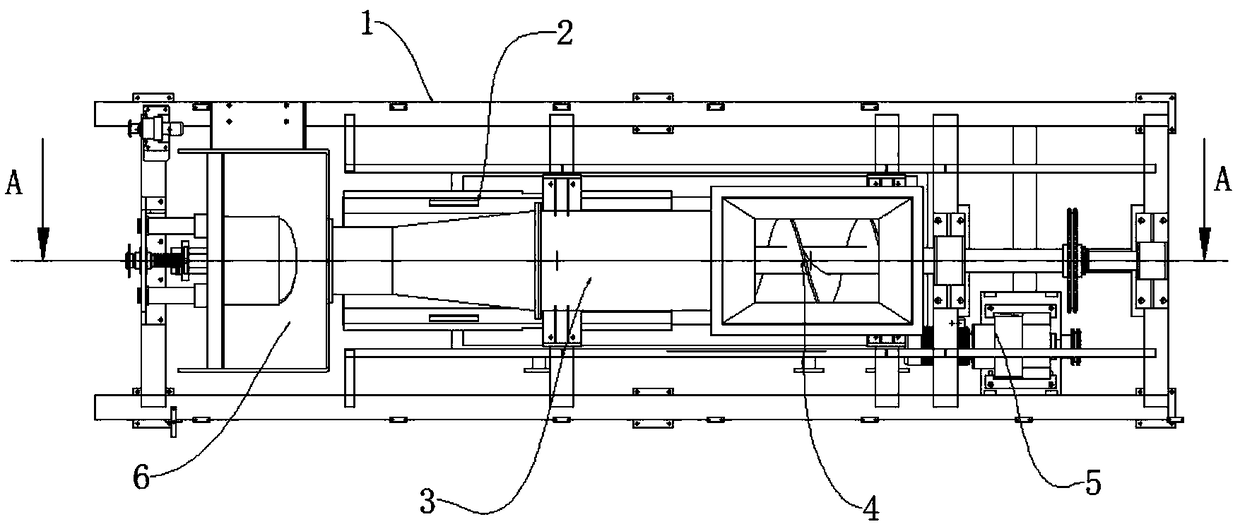

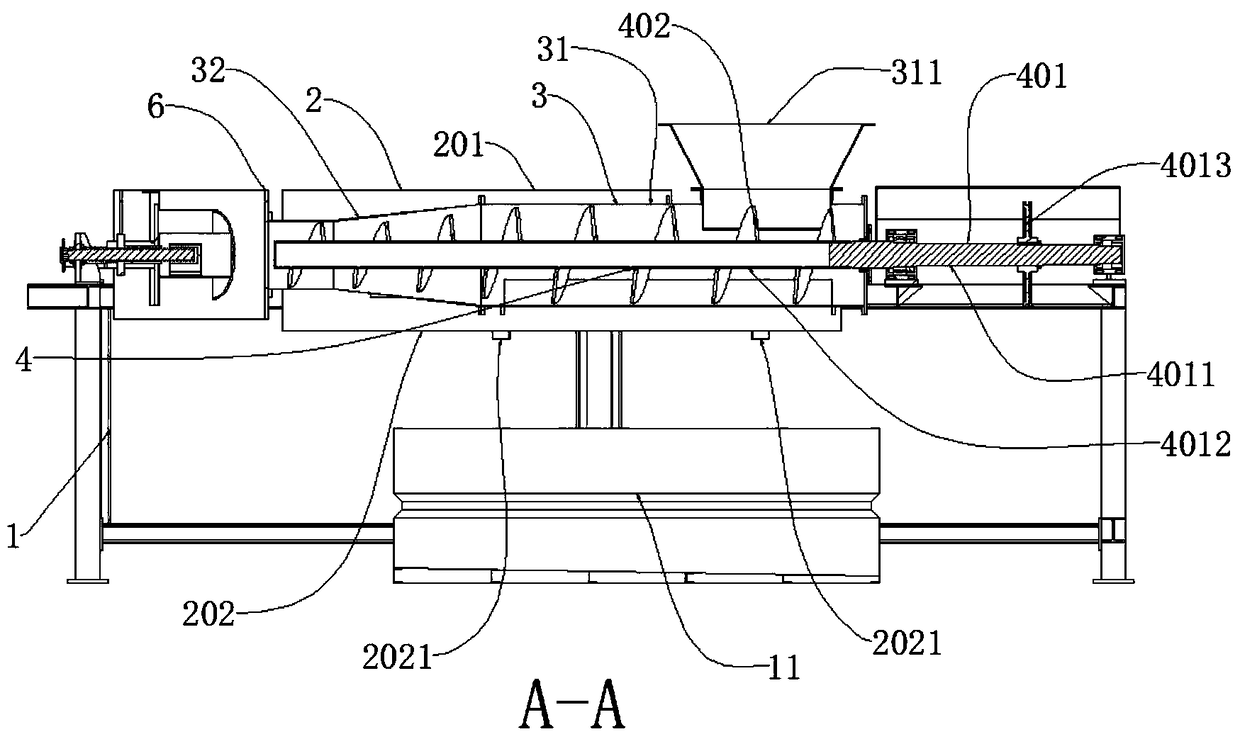

[0022] Please see attached Figure 1-6 , a screw compression device for dehydrating food waste, which includes: a frame 1, a screw compression device;

[0023] The frame 1 is a cuboid frame structure, and the bottom is provided with a waste water receiving tank 11;

[0024] The screw compression device is arranged on the upper part of the waste water receiving tank 11;

[0025] The screw compression device includes a protective cover 2, a screw compressor housing 3, an auger 4, a driving device 5, and a blocking device 6;

[0026] The protective cover 2 includes an upper protective cover 201 and a lower protective cover 202;

[0027] The lower protective cover 202 is rectangular, and is fixed on the frame 1 through the protective cover fixing frame 21;

[0028] The bottom of the lower protective cover 202 is provided with a waste water outlet 2021;

[0029] The upper protective cover 201 is arranged above the lower protective cover 202;

[0030] The screw compressor casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com