Colorized processed cheese and preparation method thereof

A processed cheese and color technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of not being able to guarantee the complete structure of protein and affecting the tensile properties of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

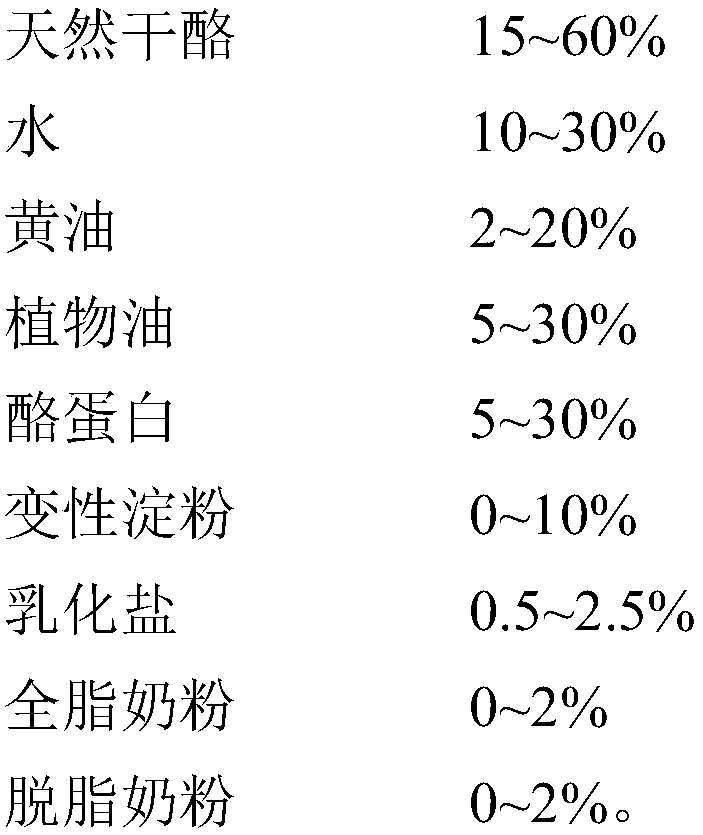

Method used

Image

Examples

Embodiment 1

[0031] A colored processed cheese slice and a preparation method thereof, comprising the following steps:

[0032] (1) Preparation of stretchable processed cheese

[0033] Mix 10kg of casein powder, 1.5kg of modified starch, 1.2kg of sodium citrate, 0.3kg of salt, 0.5kg of whole milk powder, and 1kg of skimmed milk powder to form a premix, and then mix the premix with 60kg of young cheddar cheese , 10kg of water, 2kg of butter, and 8.5kg of vegetable oil are added to a double-helix cheese melting pot (Milkylab Cuocitore-Filatrice a vaporemod.LAB 18 / 400), and the double-helix blades are started at room temperature, and the material is stirred at 120rpm with the screw speed. After 4 minutes, turn on steam for heating, heat the material to 75°C and stop the steam; the output pressure of the steam pipeline is 0.75MPa;

[0034] (2) Coloring process

[0035] Keep the screw speed at 150rpm to stir the material. When the material in the melting pot is naturally cooled to 55°C at roo...

Embodiment 2

[0040] A colored reprocessed pizza cheese shreds and a preparation method thereof, comprising the following steps:

[0041] (1) Preparation of stretchable processed cheese

[0042] Mix 20kg of casein powder, 10kg of modified starch, 0.8kg of sodium citrate, 0.6kg of trisodium phosphate, 0.2kg of sodium pyrophosphate, 0.3kg of salt, 0.5kg of whole milk powder, and 0.7kg of skimmed milk powder to form a premix. Then add the premix and 15kg of young cheddar cheese, 25kg of water, 4.4kg of butter, and 20kg of vegetable oil into a double-screw cheese melting pot (Milkylab Cuocitore-Filatrice a vapor mod. LAB18 / 400), and start the double-screw at room temperature The blade is used to stir the material at a screw speed of 120rpm. After stirring for 4 minutes, heat the material with steam, and stop the steam after heating the material to 75°C; the output pressure of the steam pipeline is 0.75MPa;

[0043] (2) Coloring process

[0044] Keep the screw speed at 150rpm to stir the mater...

Embodiment 3

[0049] A colored processed cheese stick and a preparation method thereof, comprising the following steps:

[0050] (1) Preparation of stretchable processed cheese

[0051] Mix 15kg of casein powder, 5kg of modified starch, 1.2kg of sodium citrate, 0.4kg of trisodium phosphate, 0.4kg of salt, 0.5kg of whole milk powder, and 1kg of skimmed milk powder to form a premix, and then mix the premix with 40kg Add young cheddar cheese, 22.95kg of water, 2kg of butter, and 11.5kg of vegetable oil into a double-screw cheese melting pot (Milkylab Cuocitore-Filatrice a vapor mod.LAB 18 / 400), start the double-helix blades at room temperature, and use the screw Stir the material at a rotating speed of 120rpm. After stirring for 4 minutes, heat the material with steam, and stop the steam after heating the material to 75°C; the output pressure of the steam pipeline is 0.75MPa;

[0052] (2) Coloring process

[0053] Keep the screw speed at 150rpm to stir the material. When the material in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com