3D curved glass defect detection method based on stripe reflection

A curved glass and defect detection technology, which is applied in the field of intelligent optical defect detection, can solve the problems of curved glass surface detection, low detection efficiency, high missed detection rate, and high false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. The described embodiments are only some, not all, embodiments of the present invention.

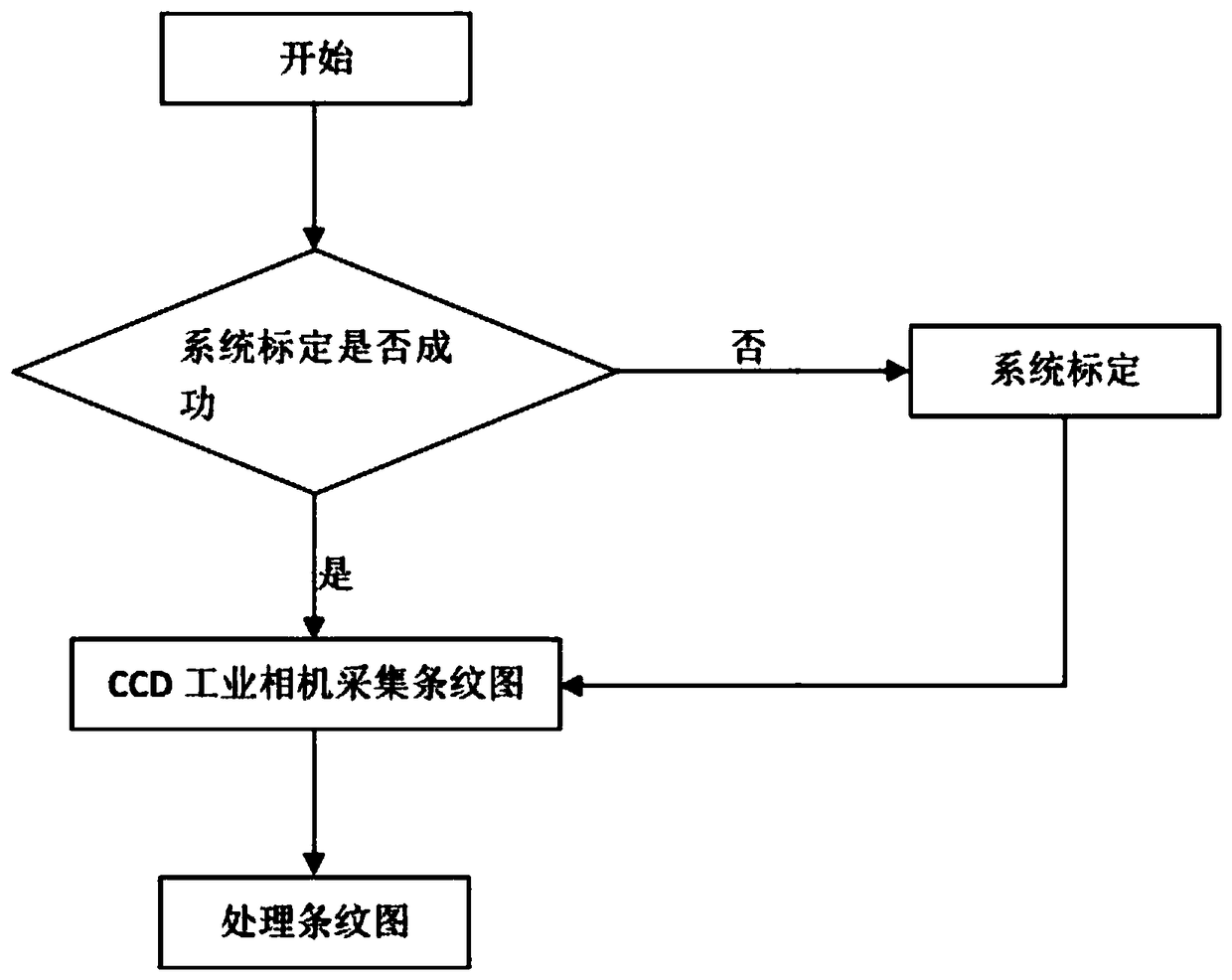

[0036] A 3D curved surface glass defect detection method based on stripe reflection in this embodiment, such as figure 1 shown, including the following steps:

[0037] Step A: System calibration;

[0038] The steps are as follows:

[0039] Step A1: camera calibration;

[0040] The method adopted in the present invention is Zhang Zhengyou’s camera calibration method based on a plane calibration target, firstly determine the initial values of the internal parameters and external parameters of the camera, then optimize the initial values by the maximum likelihood estimation method, and finally calculate the radial distortion of the camera lens;

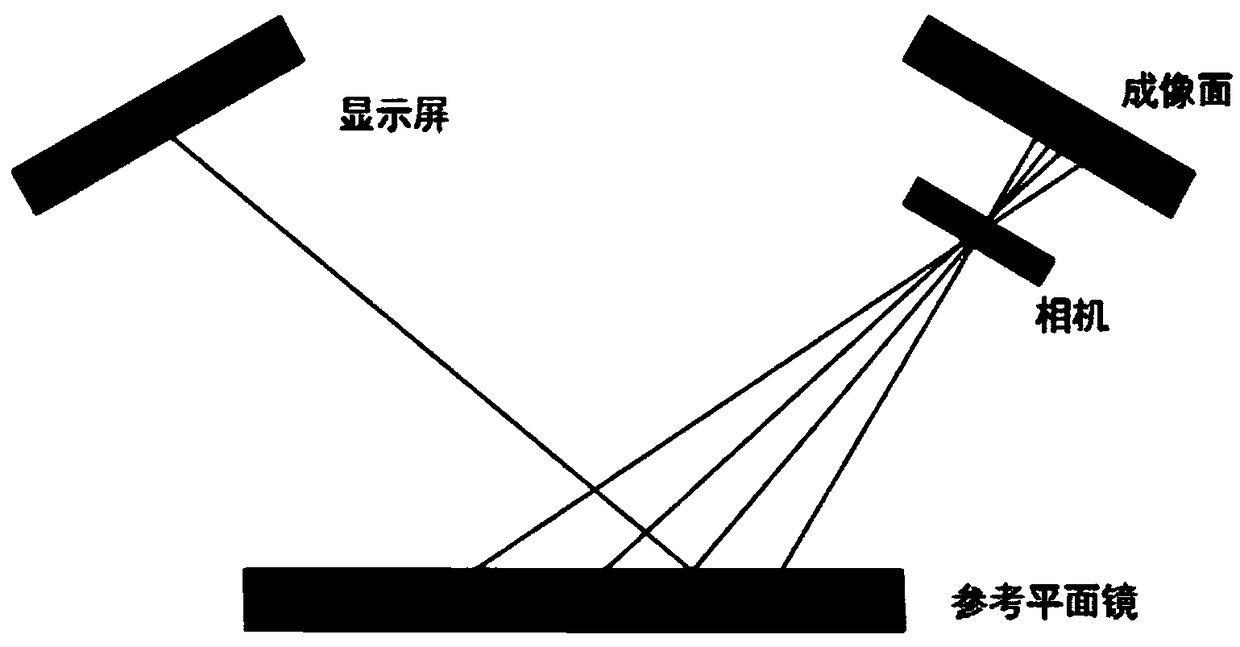

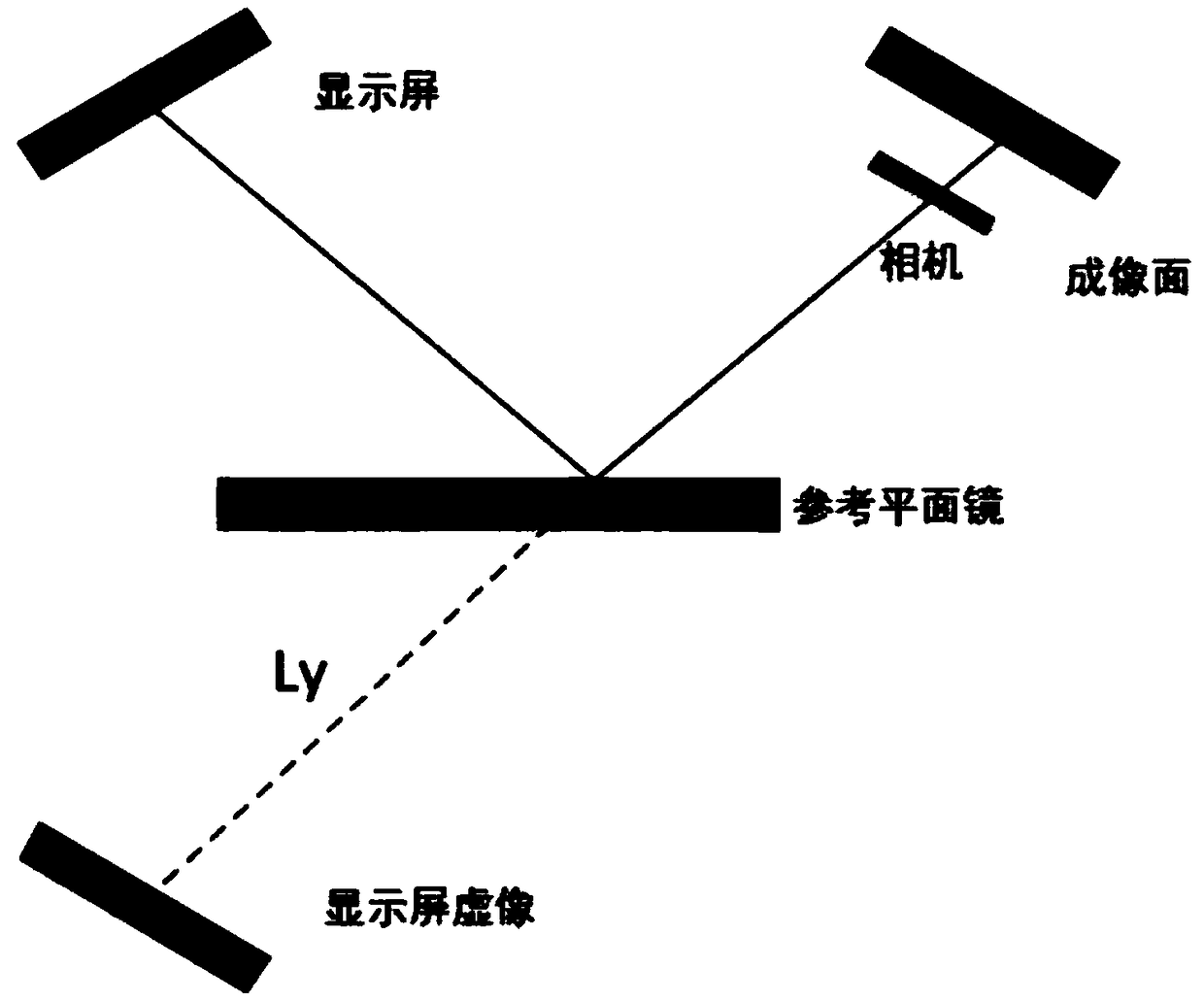

[0041] Step A2: Calibrate the position of the reference surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com