Experiment method for evaluation of fluid capacity for rock fracture forming

An experimental method and technology of ability, which is applied in the field of evaluating the fracture-making ability of fluids to rocks, and can solve the problem of ignoring the size of the fracture-making ability of fluids to rocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0099] Specific examples, such as figure 1 Shown:

[0100] The experimental method for evaluating the ability of different fluids to create fractures in rocks. The core comes from a tight sandstone in an oilfield. The specific process is as follows:

[0101] Step 1: Put the standard cylindrical core into a constant temperature drying box, and dry it continuously for 24 hours at a constant temperature of 100 degrees Celsius to remove the liquid in the core;

[0102] Step 2: test the height h, diameter d and quality m of the dry core, and calculate the density ρ of the dry core by formula (1);

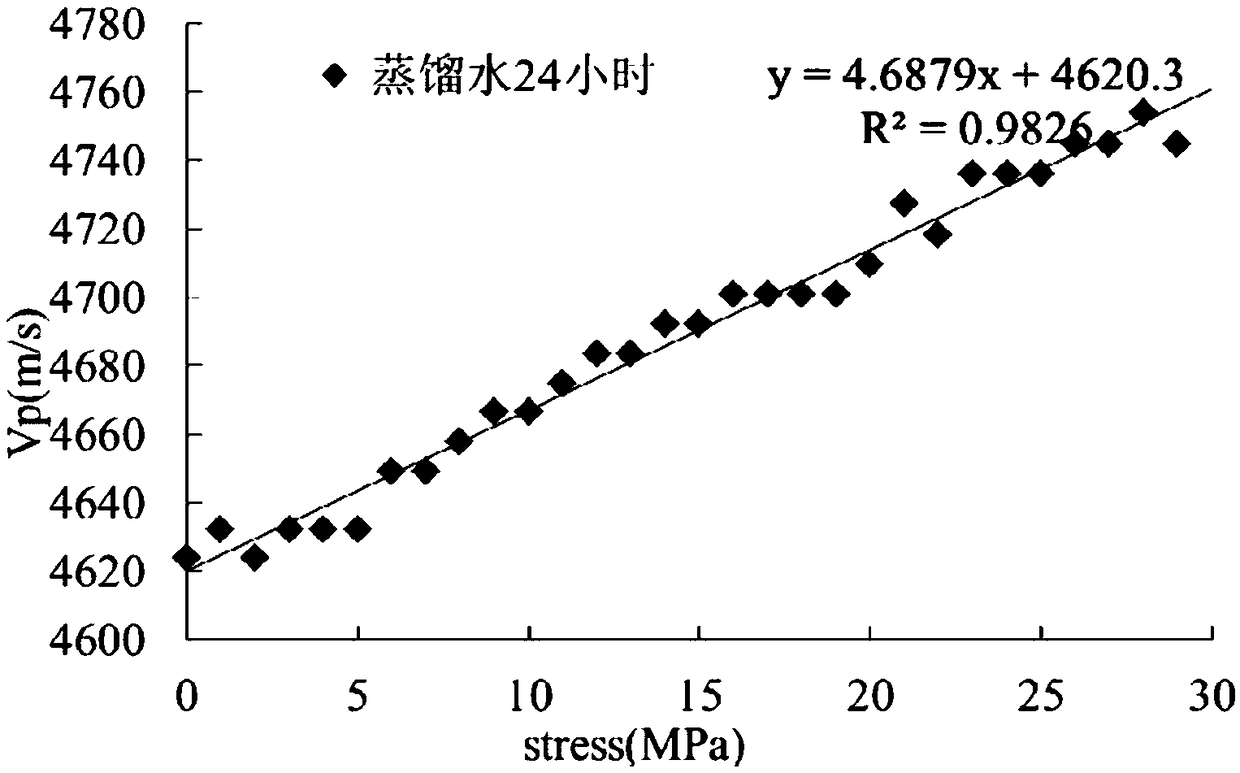

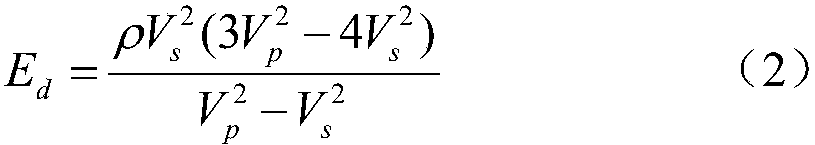

[0103] Step 3: Test the longitudinal wave and shear wave of the dry core along the axial direction, and calculate its dynamic elastic modulus E according to formulas (2) and (3). d and dynamic Poisson's ratio ν s size;

[0104] Step 4: Convert the dynamic rock mechanics parameters obtained in Step 3 into static rock mechanics parameters, the conversion formula is: E s =0.85E d and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com