Novel hoop and assembly method thereof

An assembly method and clamp technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problem that bolts affect assembly efficiency and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

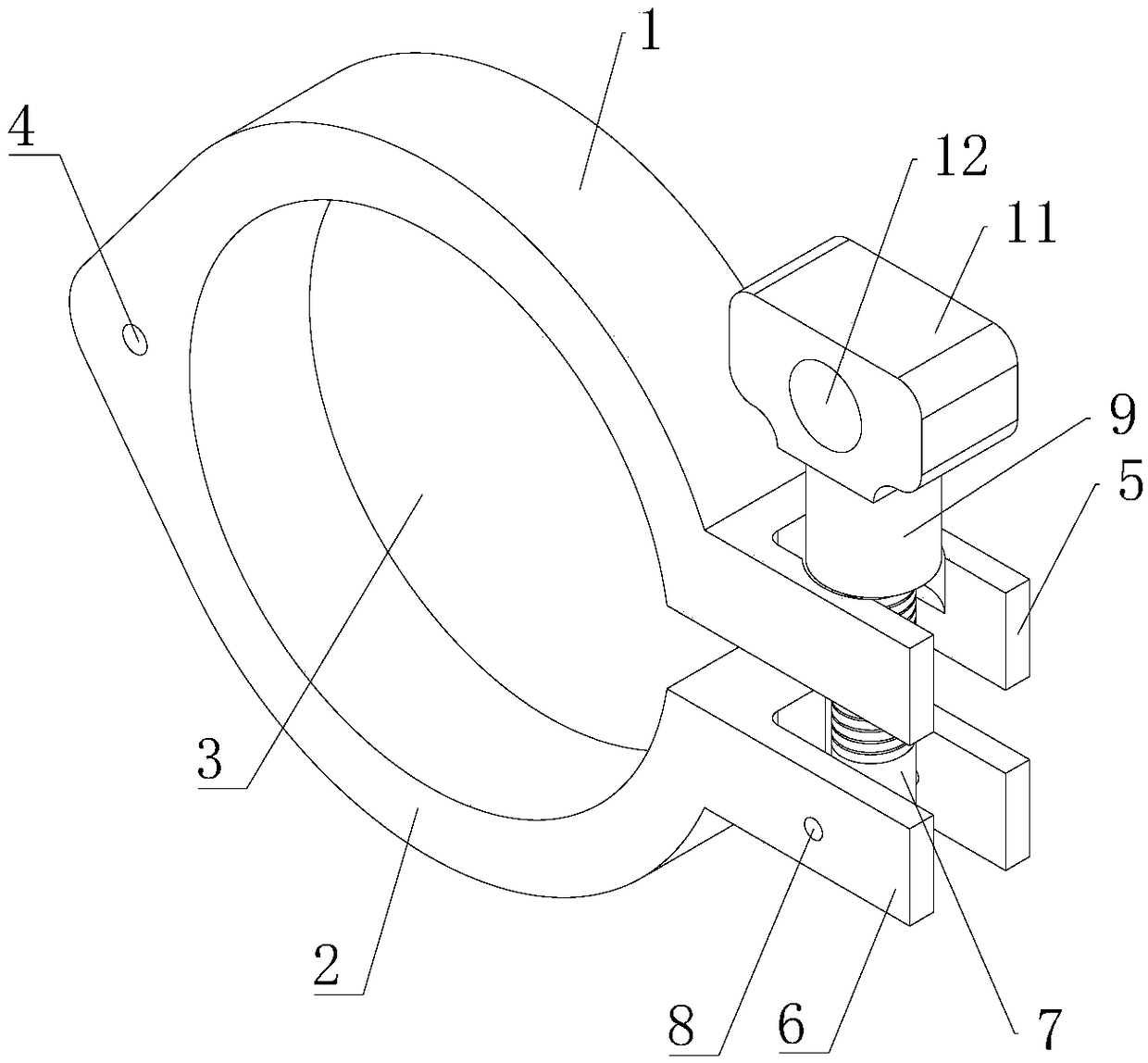

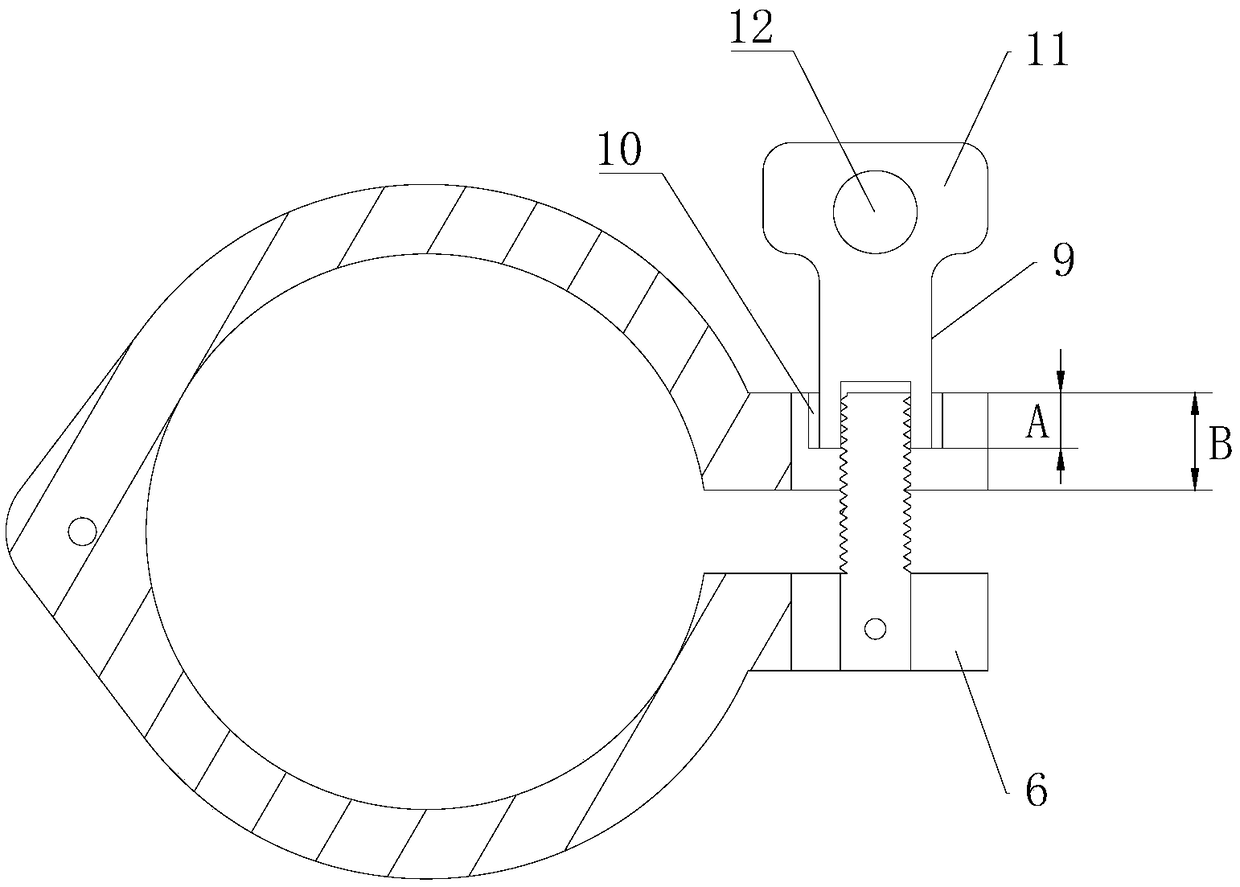

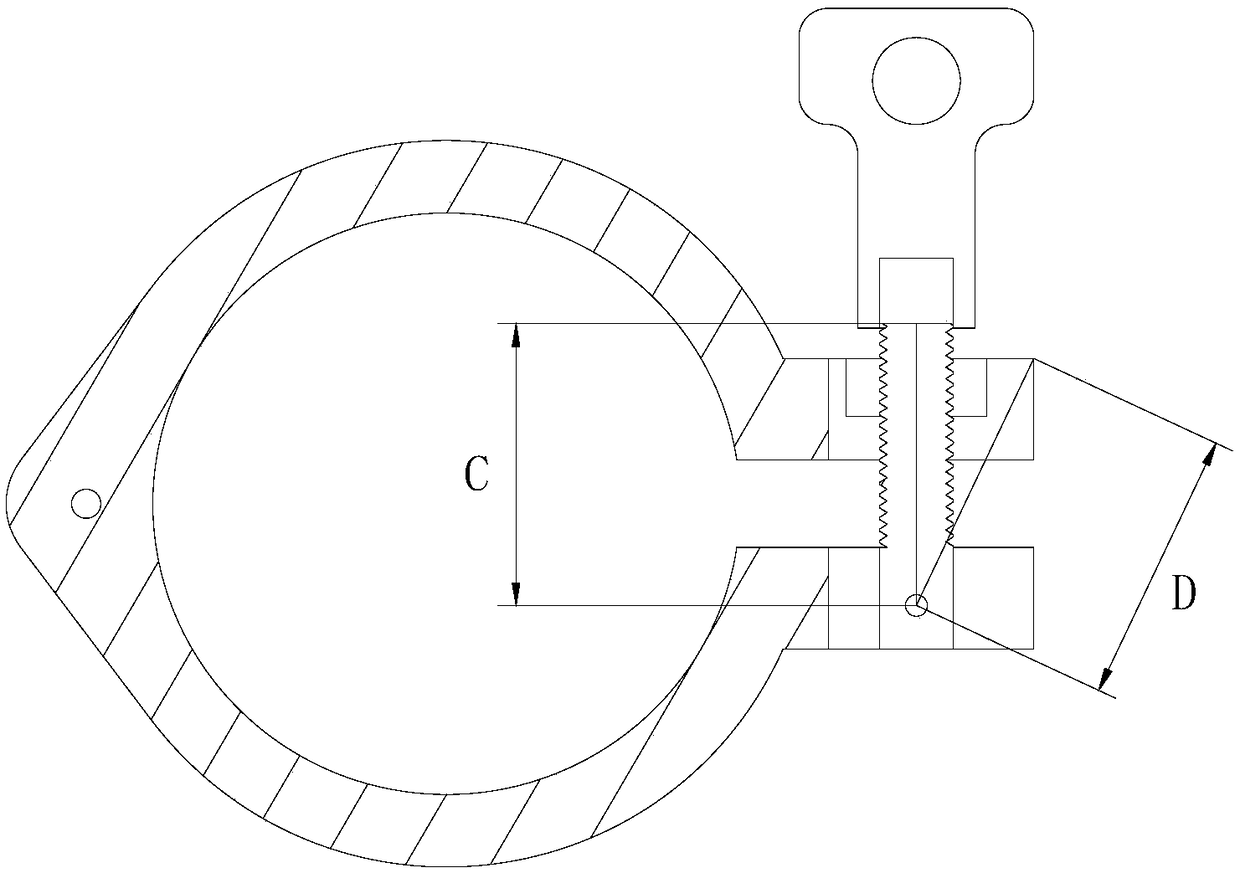

[0029] like Figure 1 to Figure 4 As shown, it is an embodiment of the novel clamp of the present invention, which has an upper clamp 1, a lower clamp 2, and a first hinge shaft 4 with the same structure as the common clamp, and the upper clamp 1 and the lower clamp 2 are both It is semicircular, and the two are oppositely arranged, and one end is connected with the first hinge shaft 4, so that the upper clamp 1 and the lower clamp 2 form a circular channel 3, and the two can use the first hinge shaft 4 as the rotation axis Realize opening and closing. When in use, pass the pipes to be connected through the circular passage 3, and use the clamping action of the upper clamp 1 and the lower clamp 2 to realize the connection of the pipelines.

[0030] The other ends of the upper clamp 1 and the lower clamp 2 are fixed with U-shaped clamping grooves, that is, the upper U-shaped clamping groove 5 and the lower U-shaped clamping groove 6, and the upper U-shaped clamping groove 5 an...

Embodiment 2

[0035] The present invention also proposes a novel clamp assembly method, which includes the following sequence steps

[0036] S1. Remove the nut from the bolt, the bolt is rotated out of the U-shaped groove of the upper clamp, and the gap between the upper clamp and the lower clamp is opened;

[0037] S2. Sleeve the upper clamp and the lower clamp on the pipeline to be connected, and merge the upper clamp and the lower clamp;

[0038] S3. Rotate the bolt around the second hinge shaft until it is rotated into the U-shaped slot of the upper clamp;

[0039] S4. Screw the nut on the bolt so that the nut is embedded in the groove of the U-shaped groove of the upper clamp;

[0040] S5. Continue to screw the nut until it rests on the bottom surface of the groove.

[0041] In the above step S5, the screwing shaft can be inserted into the screwing hole, and the screwing shaft can be rotated to realize the screwing of the nut.

[0042] The novel clamp and its assembly method of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com