Observation method for multi-segment graded depressurization water injection based on fracture observation

A step-down and multi-stage technology, which is applied in surveying, earthwork drilling, wellbore/well components, etc., can solve problems such as unsuitable control of water pressure, mechanical failure, and large range of water pressure conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described in detail below with reference to specific embodiments.

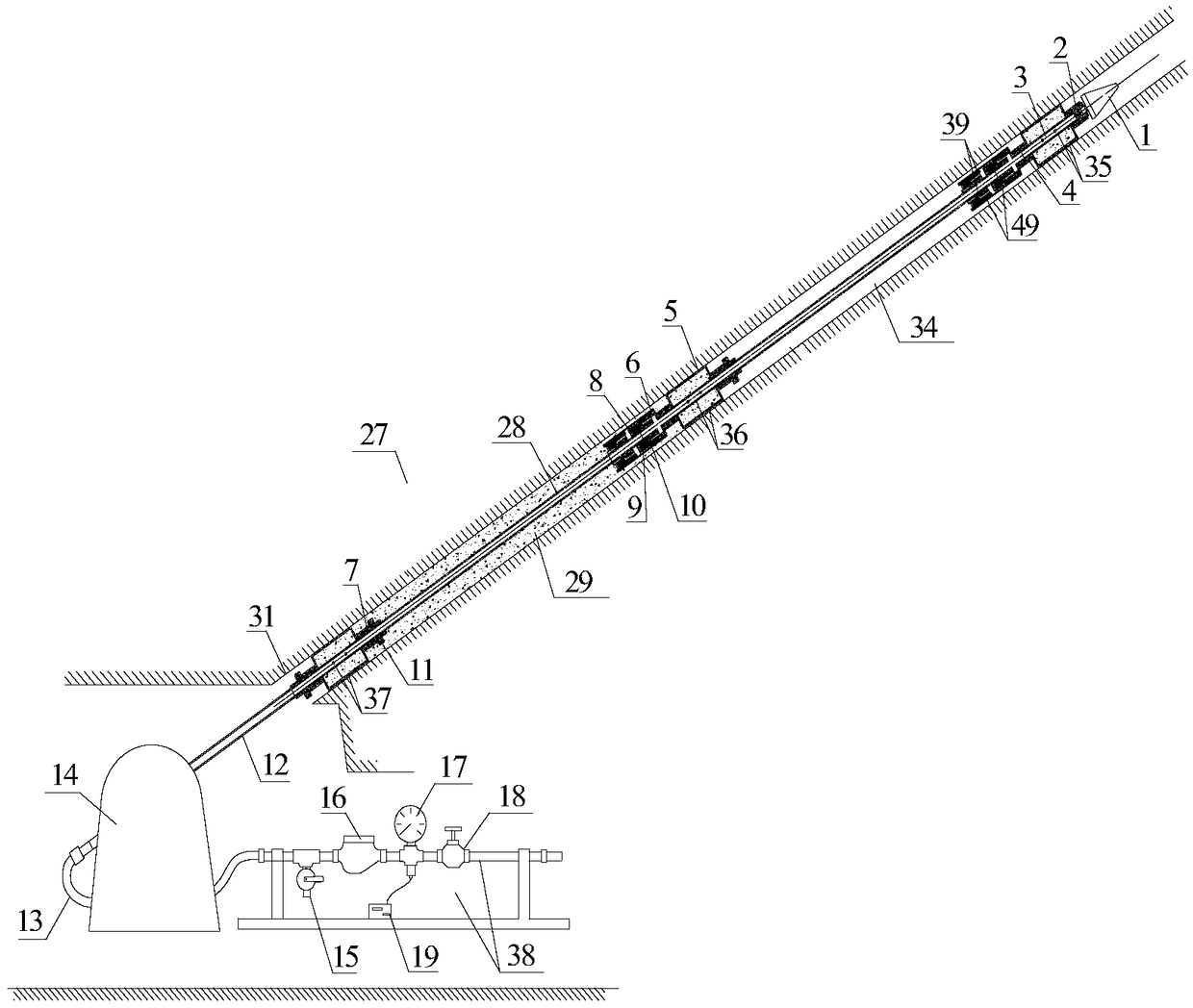

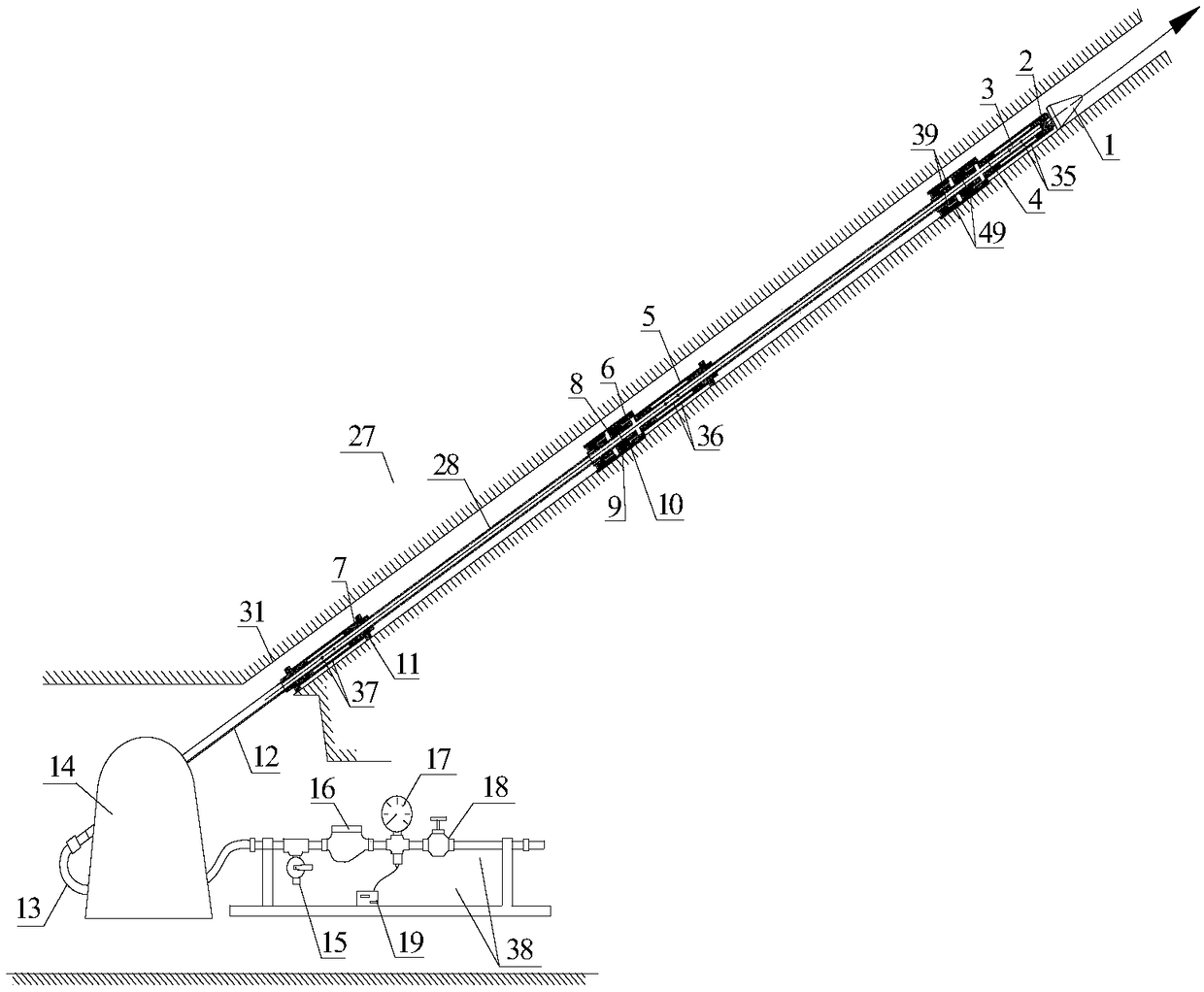

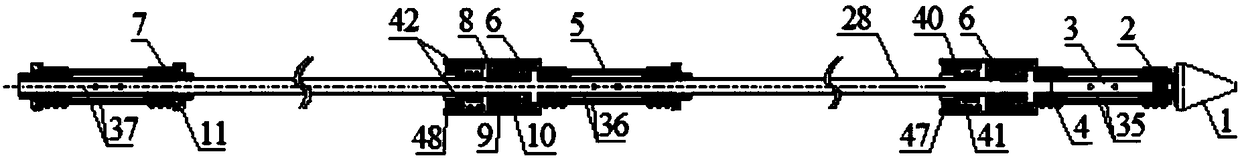

[0072] like Figure 1-3 As shown in , a multi-stage step-down depressurization water injection device based on fracture observation, including a test probe, a propulsion system and a control system;

[0073] The test probe includes an occluder, a partial pressure assembly 49 and a connecting pipe 28, the occluder further includes a front occluder 35, a middle occluder 36 and a tail occluder 37, and the front occluder 35 , the middle occluder 36, the tail occluder 37 and the borehole form the first water injection cavity 29 and the second water injection cavity 34; the partial pressure assembly 49 is installed on the front occluder 35, the middle occluder The tail part of 36 is composed of primary converter 6 and secondary converter 39, which converts the high-pressure water source in the connecting pipe 28 to the low-pressure water source and flows into No. 1 water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com