Observation method of multi-stage depressurization water injection based on fracture observation

A step-down and multi-stage technology, which is applied in measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of poor stability in the conversion process, large range of water pressure conversion, unsuitable control of water pressure, etc., to achieve Improve observation efficiency, avoid destructive effects, and have a wide range of pressure adjustment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in further detail below in conjunction with specific embodiments.

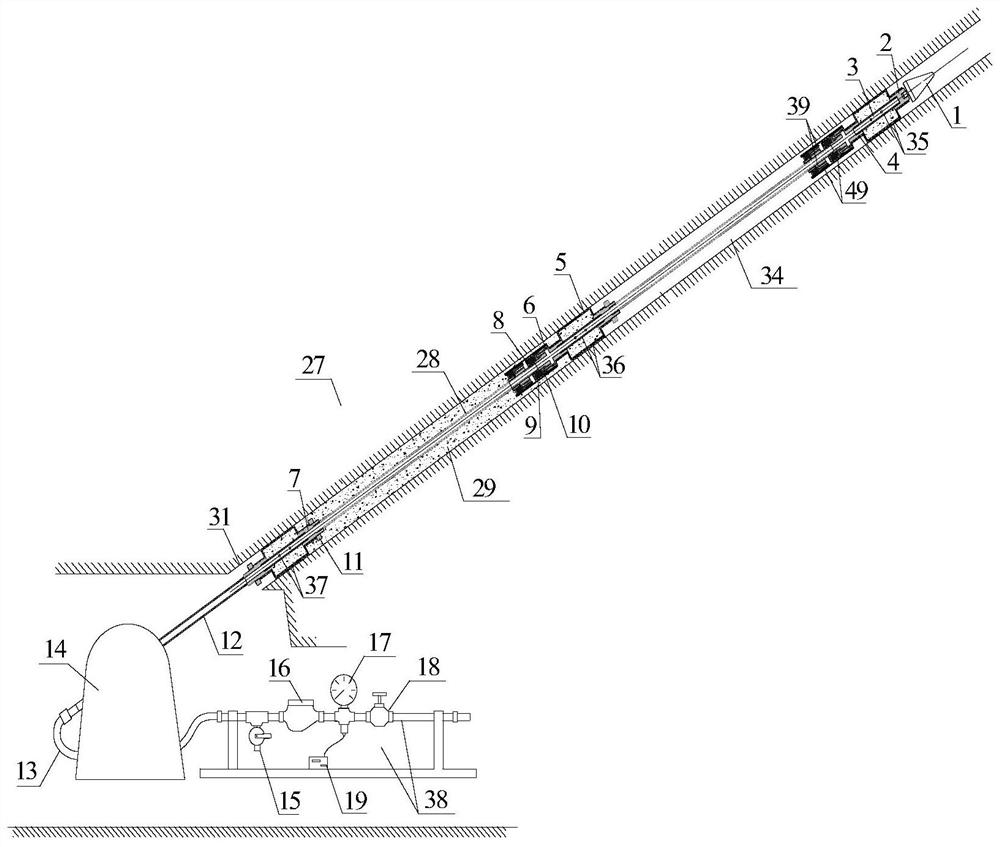

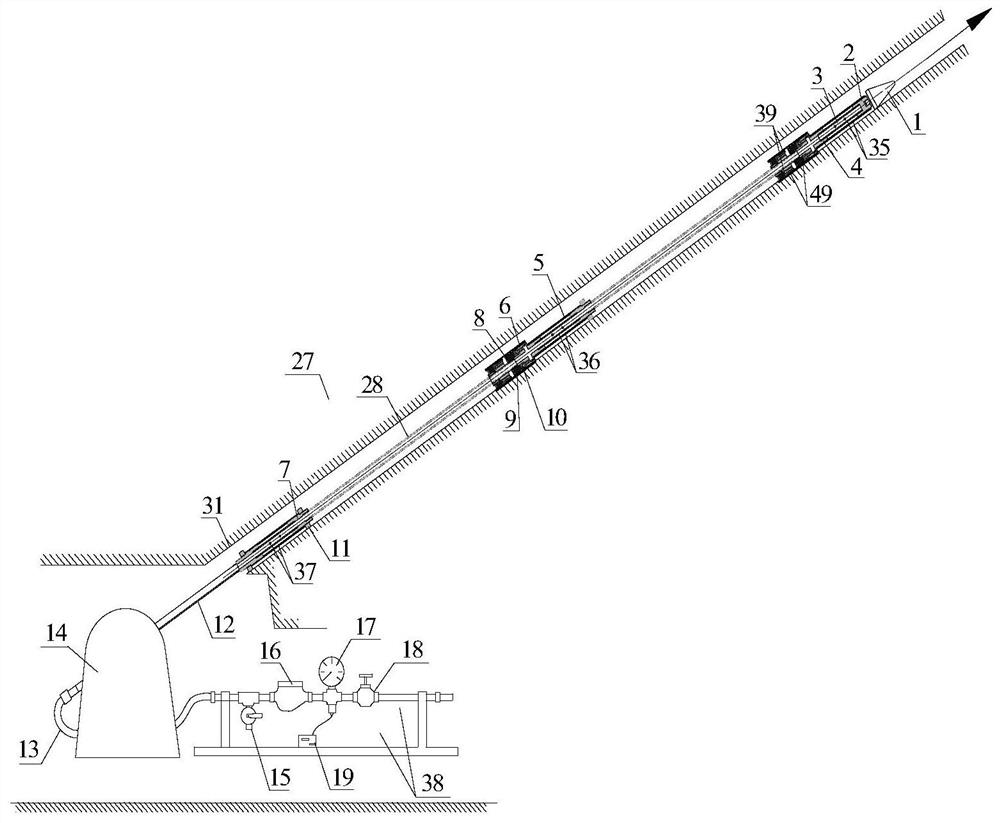

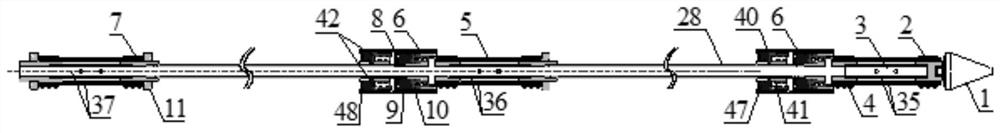

[0072] Such as Figure 1-3 As shown in , a multi-stage step-down depressurization water injection device based on fracture observation, including a test probe, a propulsion system and a control system;

[0073] The test probe includes an occluder, a partial pressure assembly 49 and a connecting pipe 28, the occluder further includes a front occluder 35, a middle occluder 36 and a tail occluder 37, and the front occluder 35 , the middle occluder 36, the tail occluder 37 and the borehole form the first water injection cavity 29 and the second water injection cavity 34; the partial pressure assembly 49 is installed on the front occluder 35, the middle occluder The tail part of 36 is composed of primary converter 6 and secondary converter 39, which converts the high-pressure water source in the connecting pipe 28 to the low-pressure water source and flows into No. 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com