Hierarchical depressurization drilling fissure detection system

A technology of graded pressure reduction and detection system, which is applied in the direction of soil material testing, measuring devices, and analysis materials, etc., can solve problems such as troublesome operation process, large water pressure conversion range, poor stability, etc., achieve a wide range of pressure regulation and avoid damage function, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

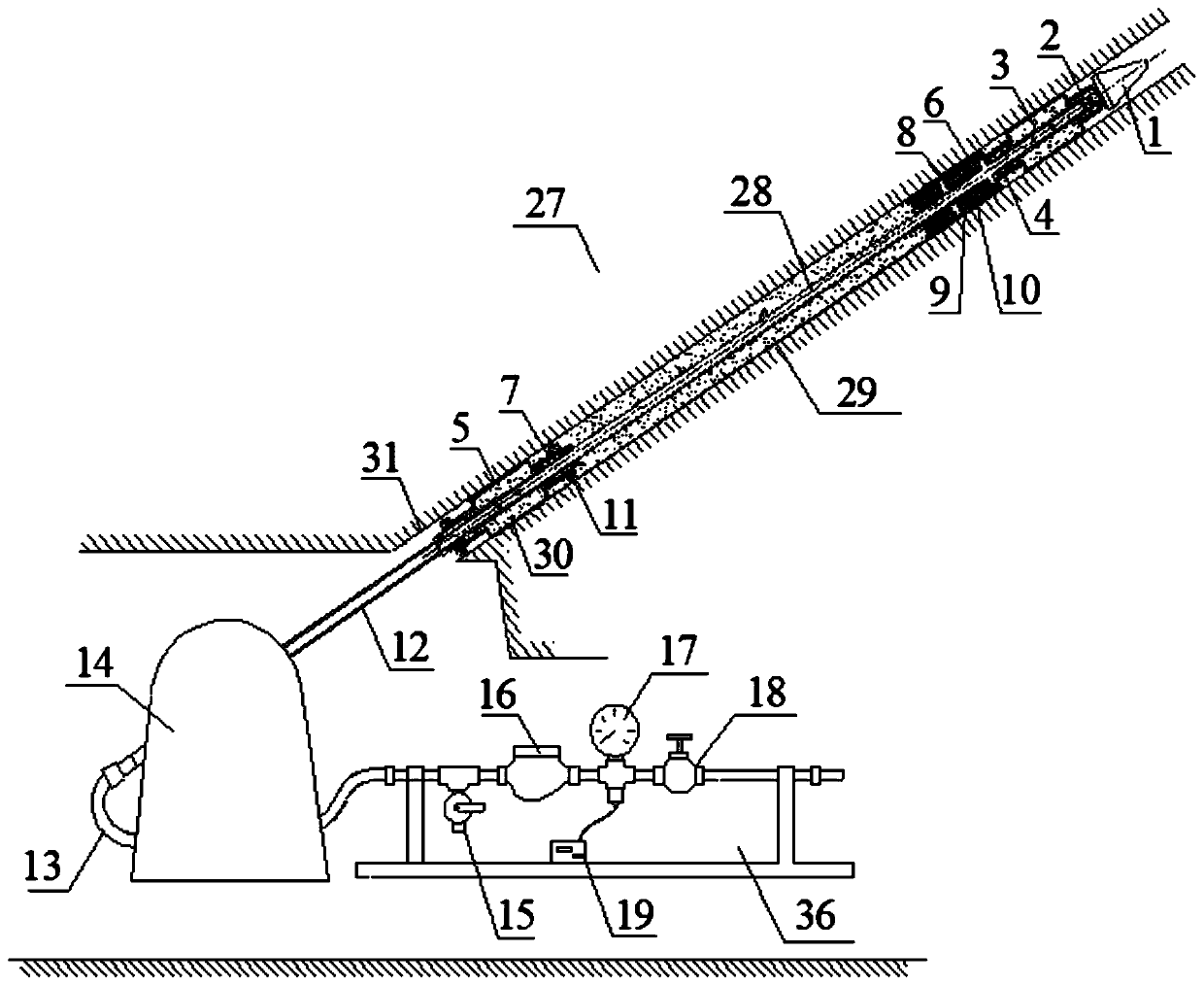

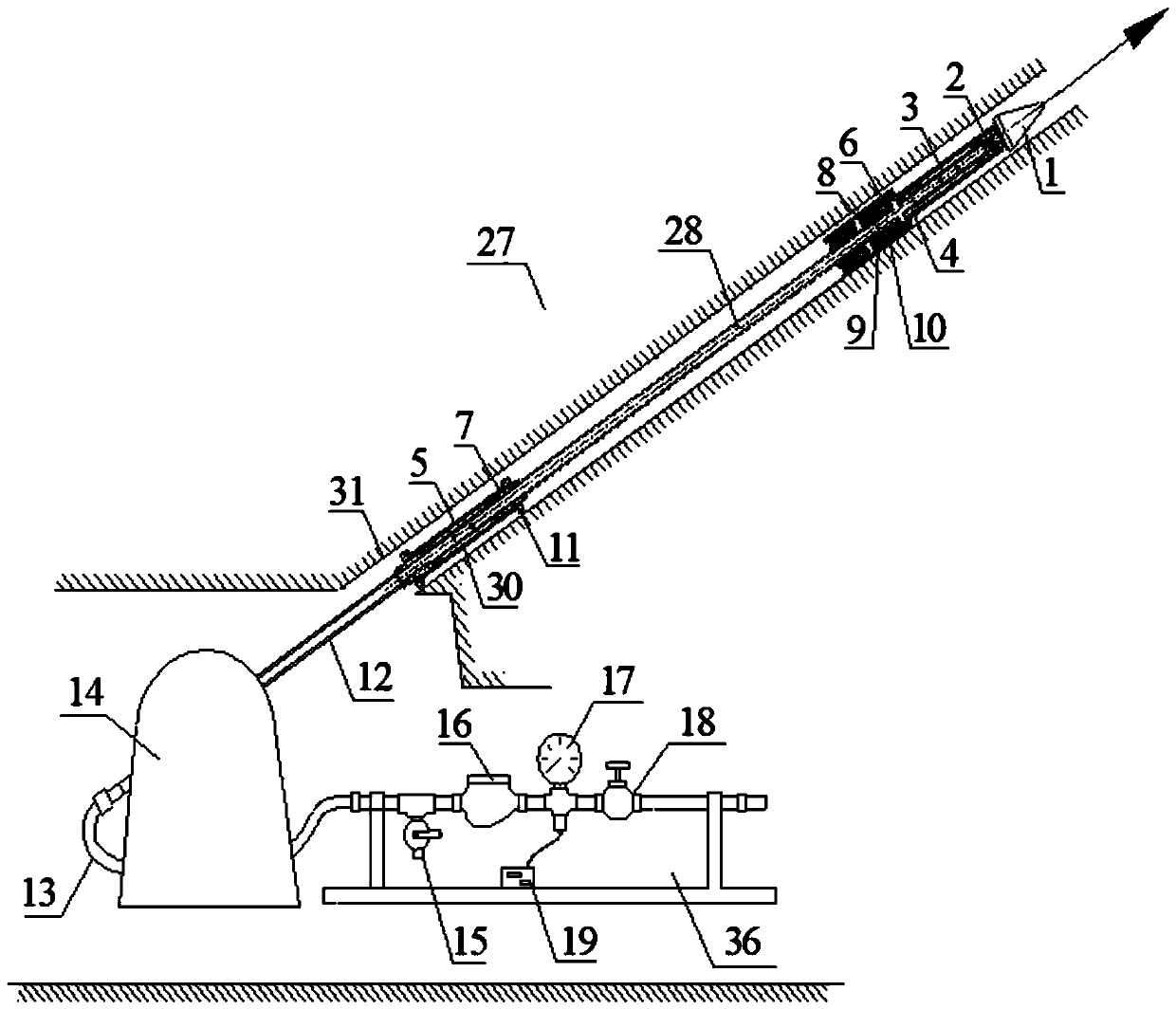

[0062] Such as Figure 1-3 As shown, a hierarchical step-down drilling fissure detection system mainly includes a test probe, a drilling rig 14 , a drill pipe 12 , and a control console 36 .

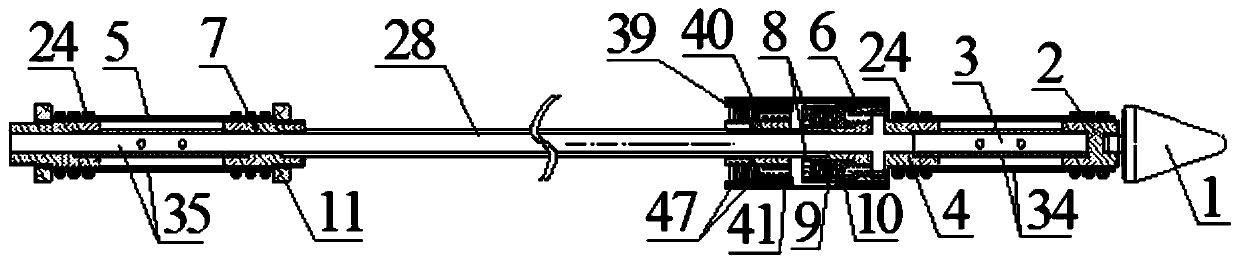

[0063] The test probe mainly includes a front occluder 34, a tail occluder 35, a pressure-dividing assembly 47 connected to the tail of the front occluder 34, and the pressure-dividing assembly 47 is blocked with the tail by a connecting pipe 28. Connected to the device 35, mainly including the primary converter 6 and the secondary converter 37, the secondary converter 37 is sleeved on the outer end of the primary converter 6, and the two are threaded, and the occluder is composed of the leakage pipe 3, a series of The joint and the rubber bag 5 are composed, and the rubber bag 5 is wrapped around the outer end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com