Anti-frostbite swelling method for mold bag concrete channel through polystyrene board

A technology of polystyrene board and mold bag concrete, which is applied in artificial waterways, water conservancy projects, construction, etc., and can solve problems such as damage, frost heaving of channels, and scrapping of channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of method that polystyrene plate is used for mold bag concrete channel frost heave prevention: specifically as follows,

[0038] S1. Construction preparation

[0039] The foundation soil of the canal bed is compacted and the canal slope is leveled when the mold bag is laid. Concrete work should not be carried out when the temperature is below 4°C. The error of slope repair shall not exceed ±2cm, otherwise the exceeding part shall be backfilled with mortar.

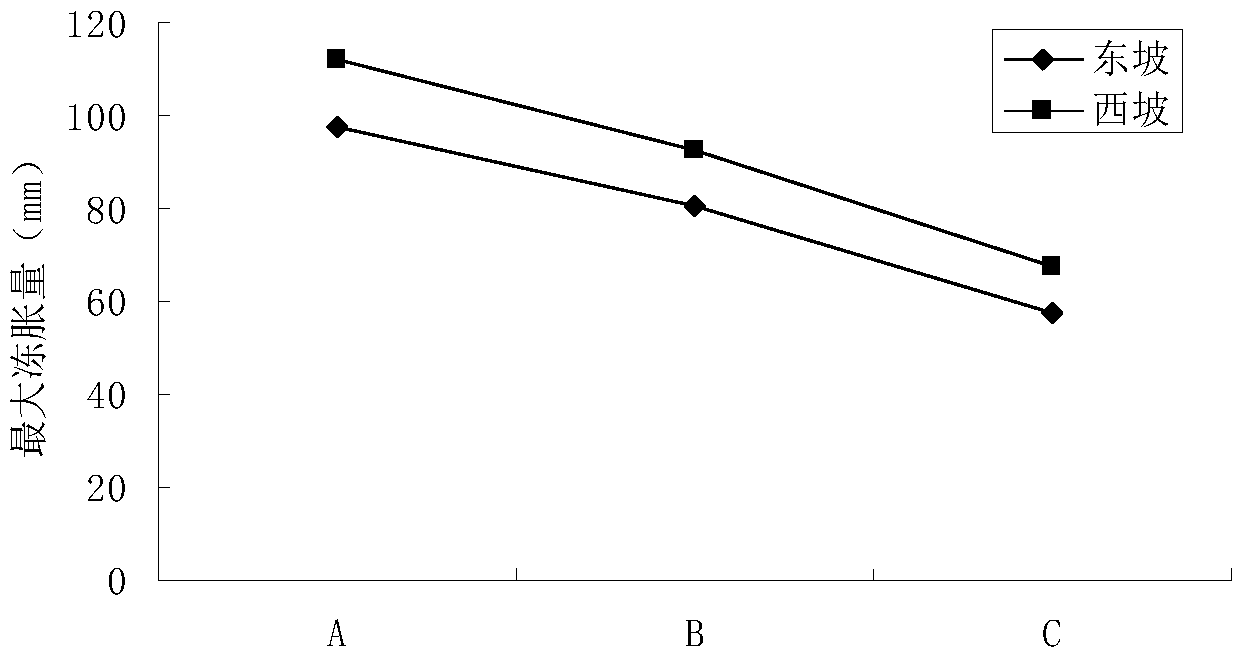

[0040] S2, laying insulation board

[0041] After the canal slope is leveled, lay polystyrene insulation boards evenly and alignedly on the canal slope. The thickness of polystyrene insulation boards depends on the thickness of the mold bag concrete pouring; under the condition of 8cm mold bag concrete, the thickness of polystyrene board laying It is 4cm. as attached figure 1 As shown, the polystyrene board 2 is laid on the slope of the canal, and the membrane bag concrete 1 is located on the polystyrene...

Embodiment 2

[0049] The difference between embodiment 2 and embodiment 1 is that under the condition of 8cm mold bag concrete, the laying thickness of polystyrene board is 6cm;

Embodiment 3

[0051] The difference between embodiment 3 and embodiment 1 is that under the condition of 8cm mold bag concrete, the laying thickness of polystyrene board is 12cm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com