Stacking-preventing type transporting and encasing device on small fruit picking robot

A picking robot and stacking technology, applied in the field of agricultural machinery, can solve the problems of high degree of mechanical damage to fruit and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

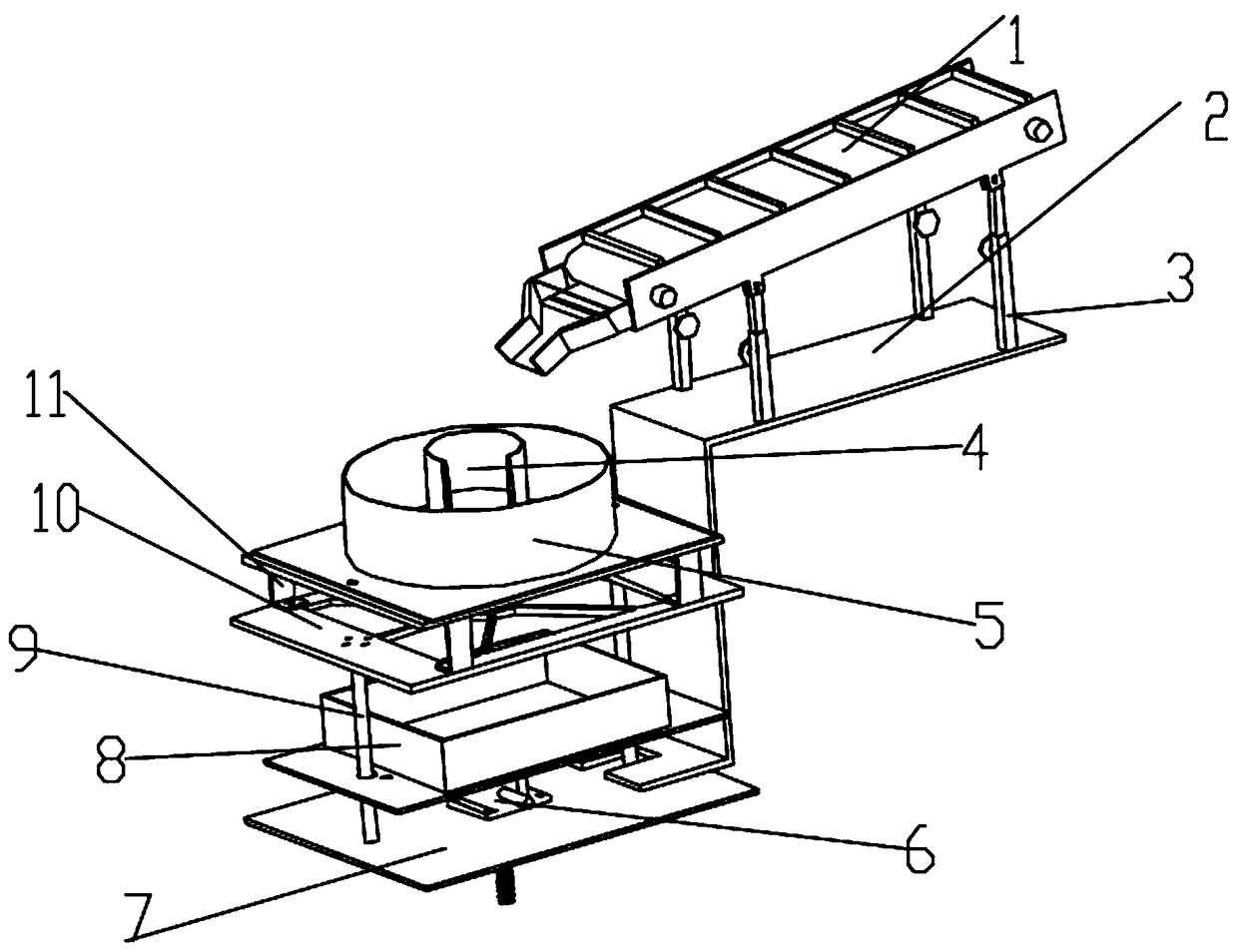

[0019] see figure 1 An anti-stacking carrying and packing device on a small fruit picking robot includes a fruit conveyor belt, a fruit dispersion packing mechanism, a fruit box position adjustment mechanism, a supporting mechanism and a control system.

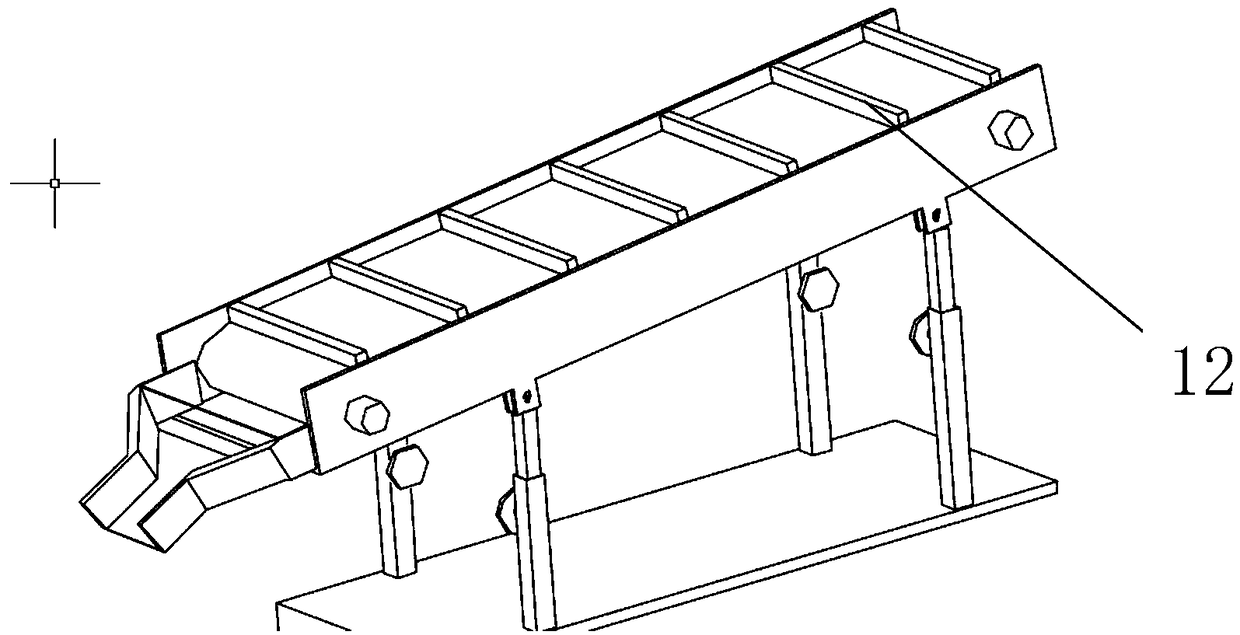

[0020] The fruit conveyor belt 1 is driven by a servo motor, and the conveyor belt is equipped with strip-shaped protrusions 12 to prevent the fruit from falling directly and causing damage to the fruit. At the same time, the support plate 2 is equipped with a height-adjustable device 3, which can adjust the transportation height and angle according to actual needs. When the fruit is transported to the conveyor belt, the motor rotates to drive the conveyor belt to transport the fruit, so that the fruit falls into the fruit dispersion packing mechanism.

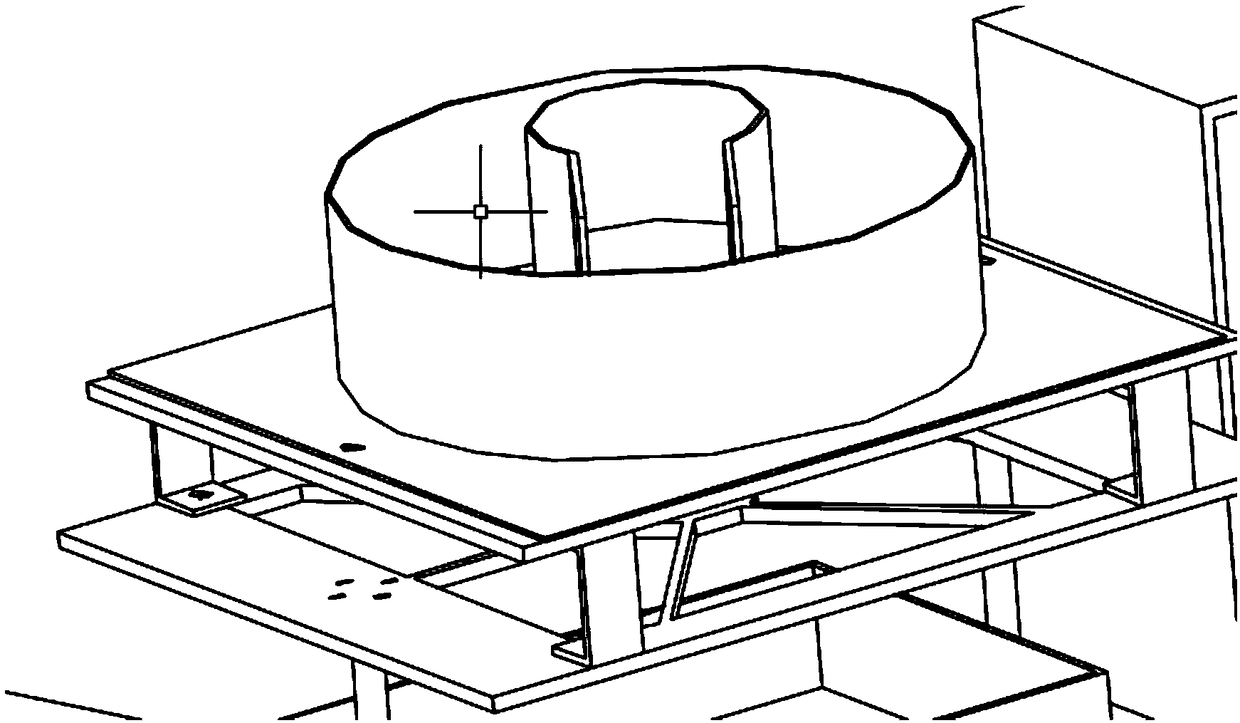

[0021] The fruit dispersing boxing mechanism is mainly composed of a rotating device 4 and a separating disc 5. The fruit falls into the rotating device, and the rotating dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com