Glass fiber reinforced plastic side skin assembly method for public transportation bus

An assembly method and glass fiber reinforced plastic technology, which can be used in motor vehicles, vehicle parts, transportation and packaging, etc., can solve the problems of waste of raw materials for replacement side skins, hazards to operators and the environment, and the existence of welding dust particles, so as to shorten vehicle maintenance time. , the effect of reducing raw material waste and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

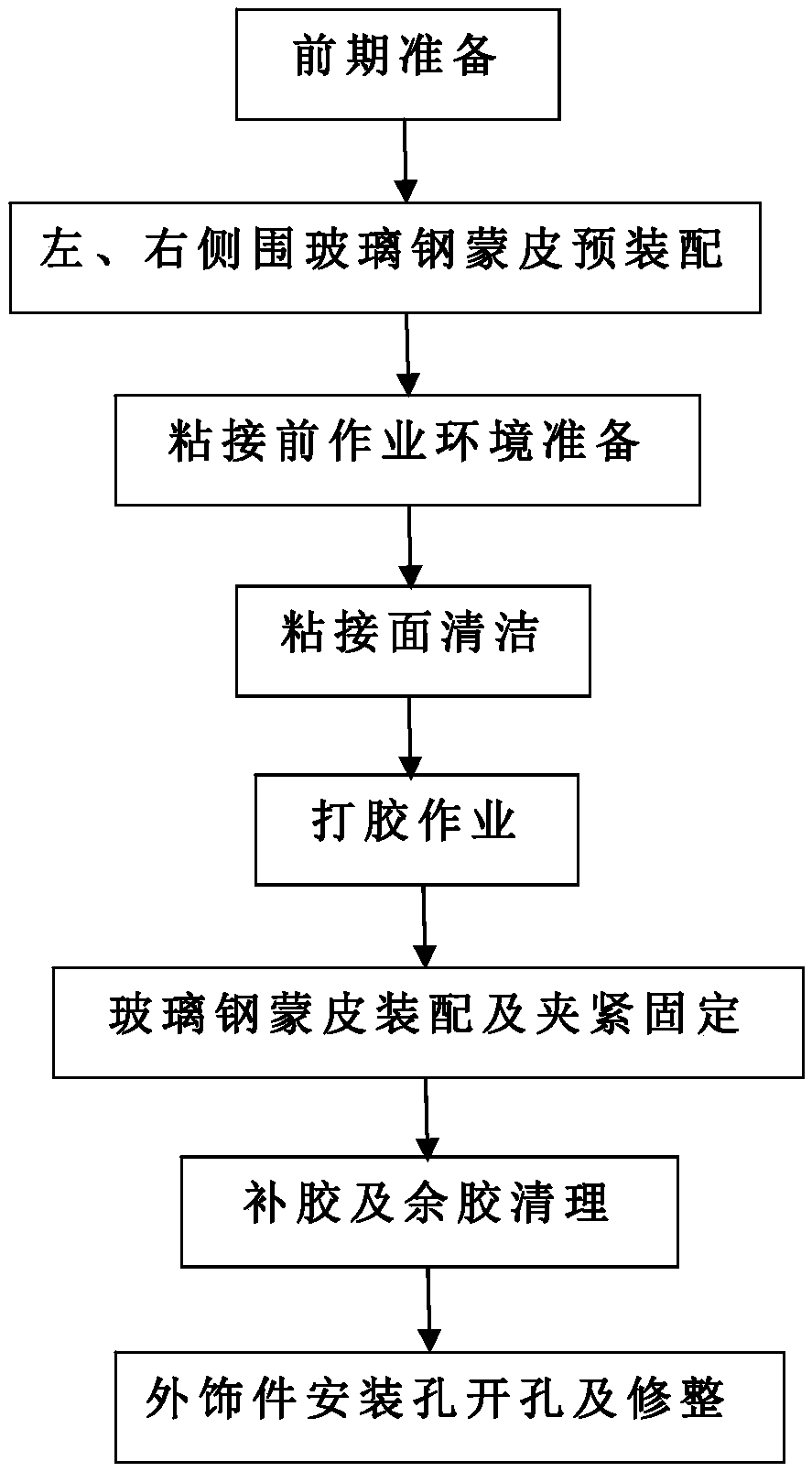

[0056] Example: refer to figure 1 Shown, a kind of bus FRP side skin assembly method comprises the following steps:

[0057] Step 1) Preliminary preparation: determination of body side frame material and surface treatment method, as well as selection of structural adhesive, primer, and cleaning agent;

[0058] 1) All bonding surfaces are required to be electrophoretic coating (ordinary square steel side frame electrophoresis), aluminum profile side frame, stainless steel side frame;

[0059] 2) Adhesive and strength tests for adhesive glue, primer, and cleaning agent used for bonding FRP side skins. According to the results, select ISR7003 sskf, ISR7005 sskf, ISR7008 AP Boss structural adhesive, Primer N41, Primer M, TS5028 primer, and industrial alcohol as cleaning agent;

[0060] 3) When the selected adhesive, primer, and cleaning agent are used for the bonding surface, all of which require electrophoretic coating (electrophoresis of the side frame made of ordinary square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com