Electromechanical finishing method for pulling flexible tool cathode and inner channel

An internal channel, tool cathode technology, applied in the direction of manufacturing tools, machining electrodes, machining special circuits, etc., can solve the problems of limiting the popularization of abrasive flow technology, and achieve the effect of improving flexibility, high processing capacity, and efficient precision machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific drawings.

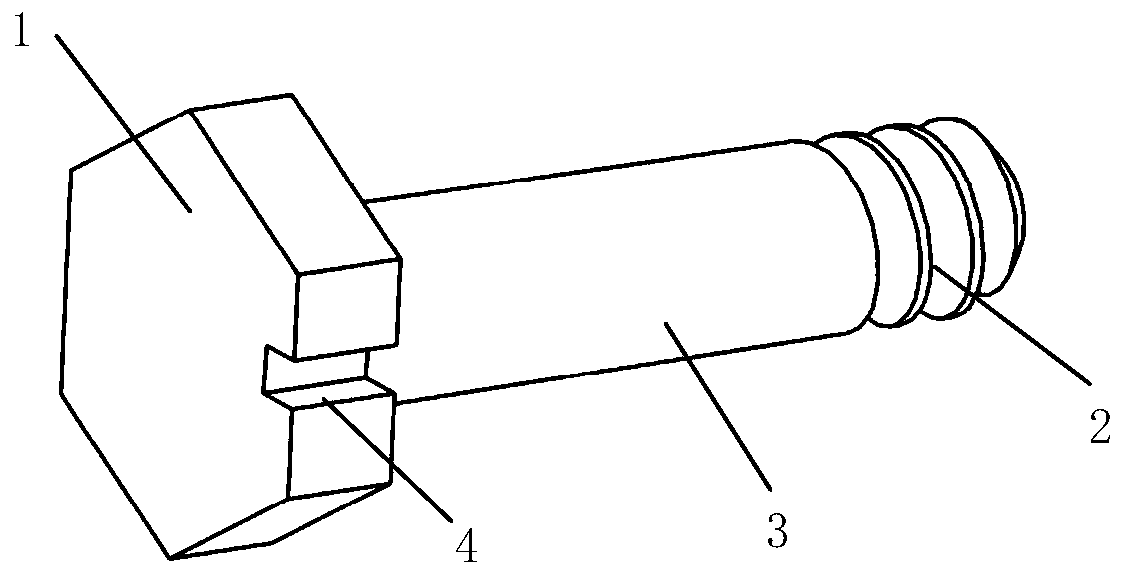

[0030] Such as Figure 1~2 As shown, the cathode of the traction type flexible tool proposed by the present invention includes a cathode bolt 1 and a flexible friction layer 7; the front end of the cathode bolt 1 is insulated to form an insulating front end 2; the middle of the cathode bolt 1 is a polished rod 3; the head of the cathode bolt 1 A head groove 4 is provided, and the head is insulated; a nut groove 6 is provided on the nut 5, and the nut 5 is insulated; the above-mentioned flexible friction layer 7 is a loose insulating material, and the outermost layer is inlaid with a hard Abrasive grains8.

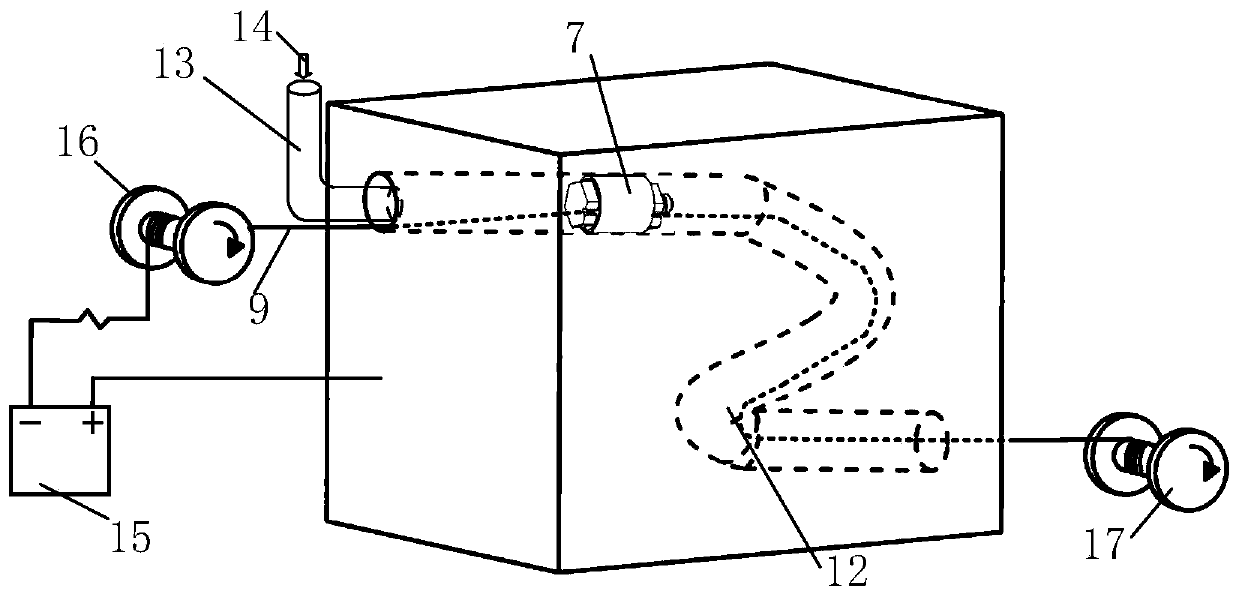

[0031] Such as image 3 As shown, the high-efficiency and precise electrolytic machining method for the internal channel of the complex component proposed by the present invention is characterized in that it includes the following steps: Step 1, one end of the m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap