Automatic hole opening device for large tank

A tank, automatic technology, applied in the direction of positioning device, boring/drilling, drilling/drilling equipment, etc., can solve the problems of low work efficiency, inconvenient opening operation, etc., to improve accuracy and facilitate opening Operation, the effect of improving the efficiency of drilling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

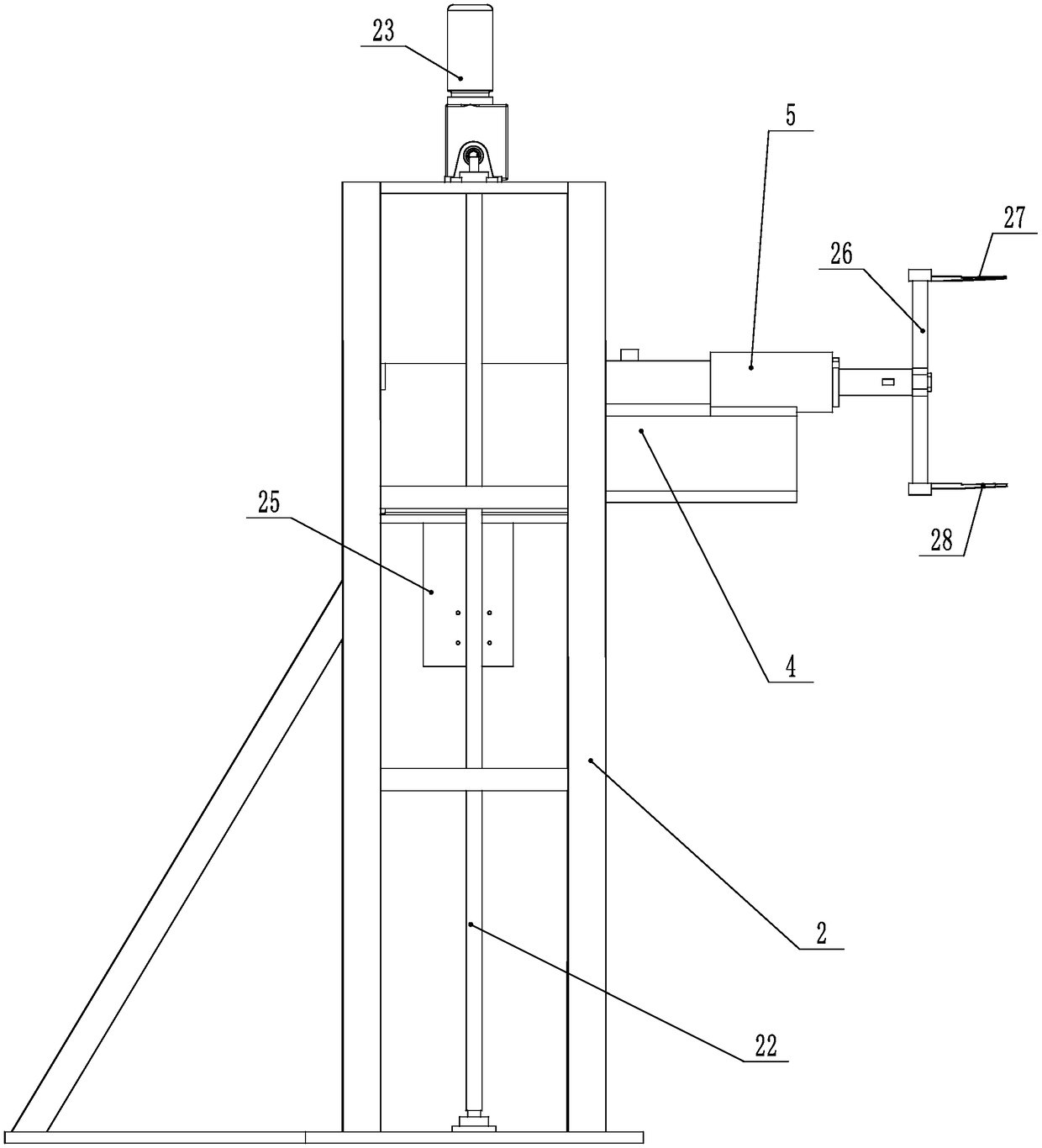

[0032] Embodiment 1: A kind of large-scale tank automatic opening device (see attached Figures 1 to 4 ), including a workbench 1 and a perforated frame 2. The workbench is circular. There is a support 3 under the workbench. The support is in the shape of a cylinder. It can be rotatably inserted in the support, and a rotating drive mechanism that can drive the workbench to rotate to any angle is installed between the workbench and the support. The rotation drive mechanism includes a turntable 7, a rotation motor 8, and a drive gear 9. The turntable is arranged on the insertion column, and the turntable is provided with meshing gears. The turntable is tightly connected with the workbench. The output shaft of the motor is connected, and the driving gear is meshed with the meshing gear for transmission. The support plate 10 is connected to the lower end of the support, and several stiffener plates 11 are connected between the support and the support plate.

[0033] A clamping mec...

Embodiment 2

[0036] Embodiment 2: A kind of large-scale tank automatic opening device (see attached Figures 5 to 7 ), its structure is similar to that of Embodiment 1, the main difference is that the clamping mechanism in this implementation includes a lifting piston cylinder 16 and a lifting column 17, the lifting column is vertically arranged and connected with the telescopic rod of the lifting piston cylinder, and the outer wall of the lifting column is at the same level There are six groups of clamping units with uniform size and structure hinged in uniform positions. The clamping unit includes a drive rod 18, a guide channel beam, a sliding seat 19, and a clamping column. The guide channel beam opens upward, and the workbench corresponds to the guide channel beam. There is a guide groove, the slide seat can be slidably installed in the guide groove beam, the guide column is connected between the clamping column and the outer end of the slide seat, the clamping column is set above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com