A water-containing blast hole mortar isolation device and isolation method thereof

A technology for isolating devices and blasting holes, applied in blasting and other directions, can solve problems such as poor isolation effect, inability to adapt to changes in the depth of mortar layers, and lower utilization rate of blasting holes, so as to achieve high utilization rate of blasting holes, increase utilization rate of explosives, The effect of saving blasting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

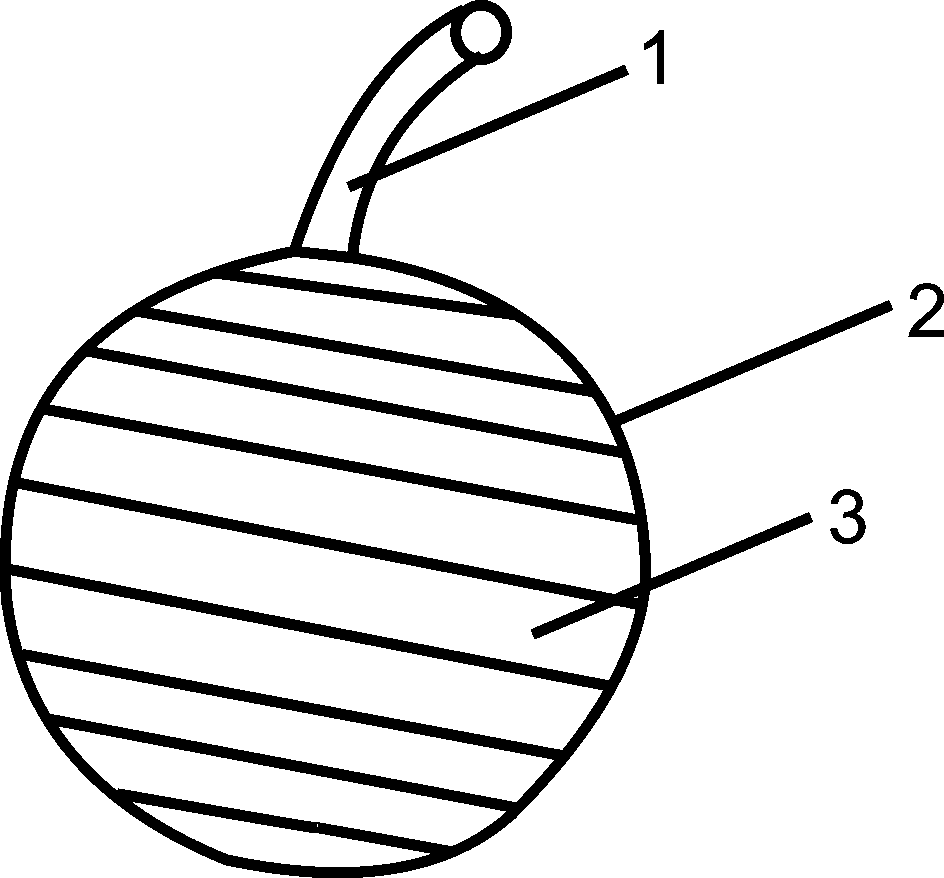

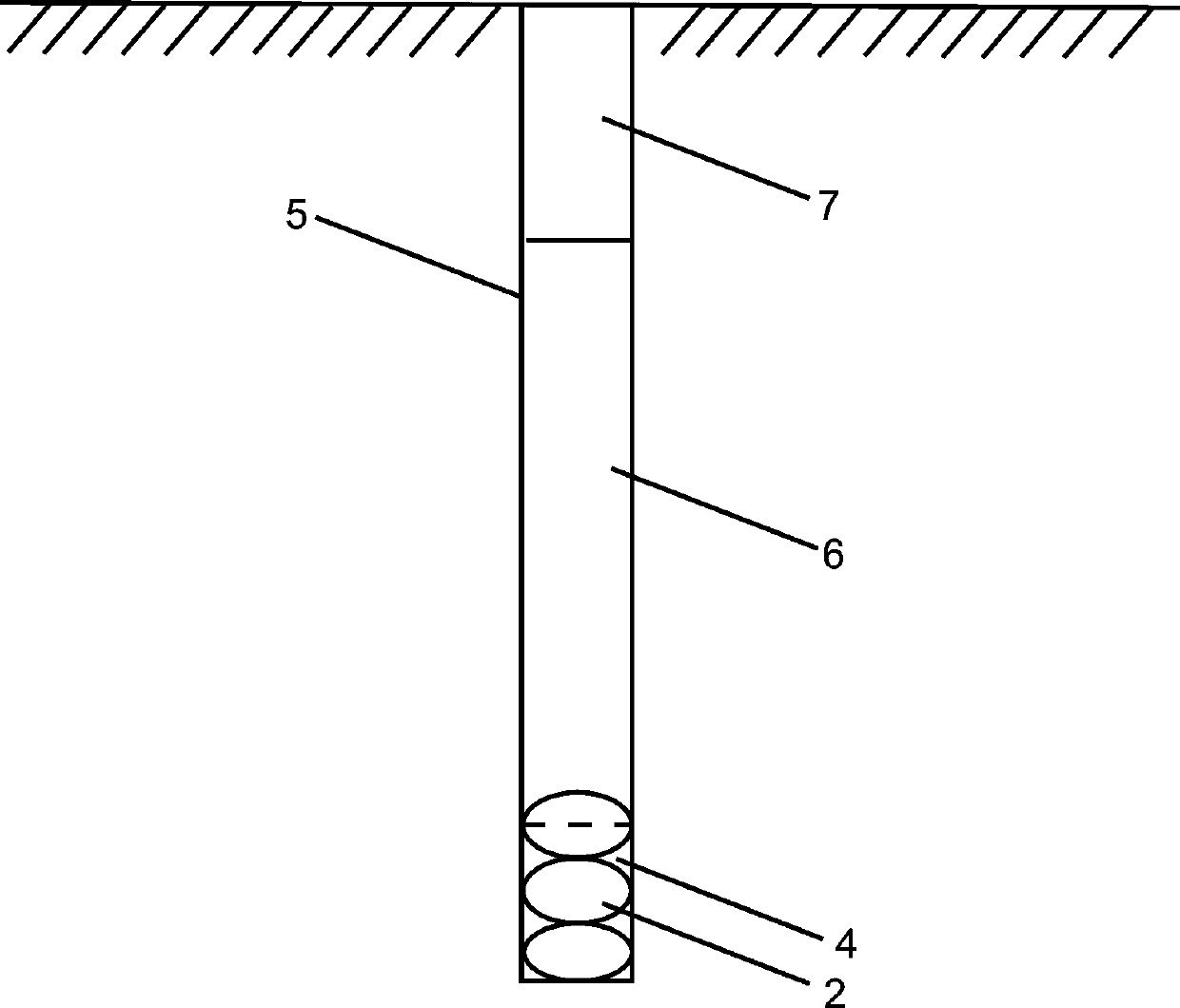

[0030] like figure 1 and figure 2 As shown, a water-containing blast hole mortar isolation device includes a hollow isolation ball made of flexible plastic film, a grouting hose 1 is communicated with the sphere 2 of the isolation ball, and the sphere 2 of the isolation ball is filled with The slurry explosive 3, the diameter of the sphere 2 filled with the slurry explosive 3 is 90-95% of the aperture of the blast hole 5.

[0031] The thickness of the flexible plastic film is ≥0.3 mm.

[0032] A method for isolating slurry explosives and mortar using the above isolating device, the method includes the following steps:

[0033] 1) Measure the depth h=140 mm of the mortar layer 4) in the blast hole 5;

[0034] 2) According to the diameter Φ=70 mm of the blast hole 5 and the hole depth H=5000 mm, combined with the depth h of the mortar layer 4 measured in step 1, calculate the diameter and quantity of the required isolation balls. The calculation process is as follows:

[00...

Embodiment 2

[0045] like figure 1 and figure 2 As shown, a water-containing blast hole mortar isolation device includes a hollow isolation ball made of flexible plastic film, a grouting hose 1 is communicated with the sphere 2 of the isolation ball, and the sphere 2 of the isolation ball is filled with The slurry explosive 3, the diameter of the sphere 2 filled with the slurry explosive 3 is 90-95% of the aperture of the blast hole 5.

[0046] The thickness of the flexible plastic film is ≥0.3 mm.

[0047] A method for isolating slurry explosives and mortar using the above isolating device, the method includes the following steps:

[0048] 1) Measure the depth h=320 mm of the mortar layer 4) in the blast hole 5;

[0049] 2) According to the diameter of the blast hole 5 = Φ = 120 mm and the hole depth H = 9000 mm, combined with the depth h of the mortar layer 4 measured in step 1, calculate the diameter and quantity of the required isolation balls. The calculation process is as follows:...

Embodiment 3

[0060] like figure 1 and figure 2 As shown, a water-containing blast hole mortar isolation device includes a hollow isolation ball made of flexible plastic film, a grouting hose 1 is communicated with the sphere 2 of the isolation ball, and the sphere 2 of the isolation ball is filled with The slurry explosive 3, the diameter of the sphere 2 filled with the slurry explosive 3 is 90-95% of the aperture of the blast hole 5.

[0061] The thickness of the flexible plastic film is ≥0.3mm.

[0062] A method for isolating slurry explosives and mortar using the above isolating device, the method includes the following steps:

[0063] 1) Measure the depth h=180 mm of the mortar layer 4) in the blast hole 5;

[0064] 2) According to the diameter Φ=200 mm of the blast hole 5 and the hole depth H=6000 mm, combined with the depth h of the mortar layer 4 measured in step 1, calculate the diameter and quantity of the required isolation balls. The calculation process is as follows:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com