Filter material with function of removing tobacco smell

A technology of function and filter material, applied in the field of filter material with the function of removing smoke smell, can solve the problems of not being able to remove smoke smell and not having the performance of removing smoke smell and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

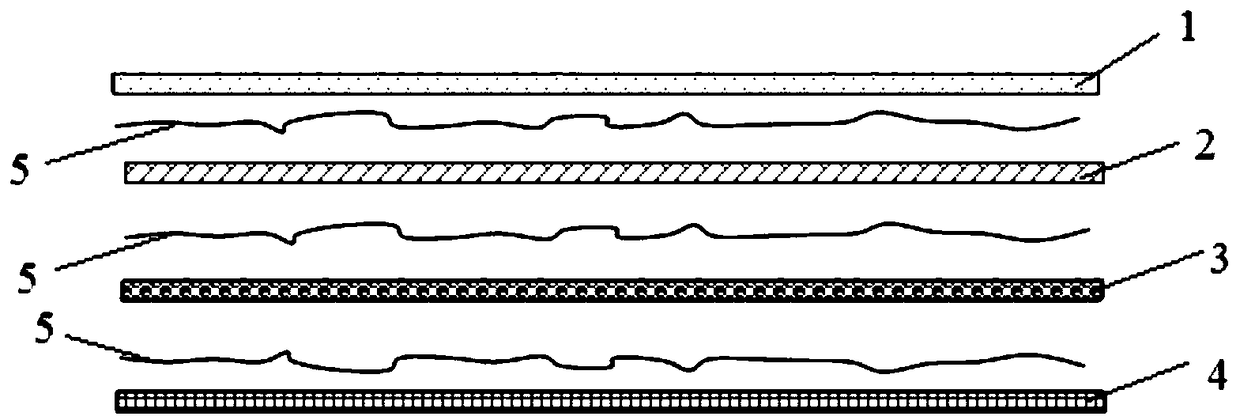

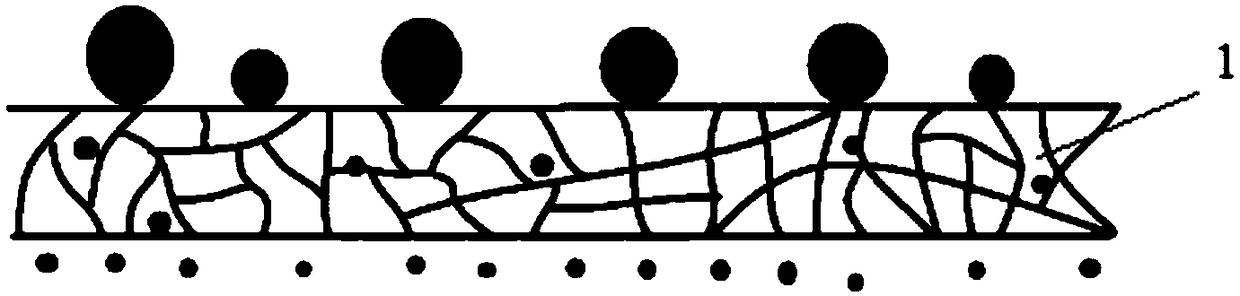

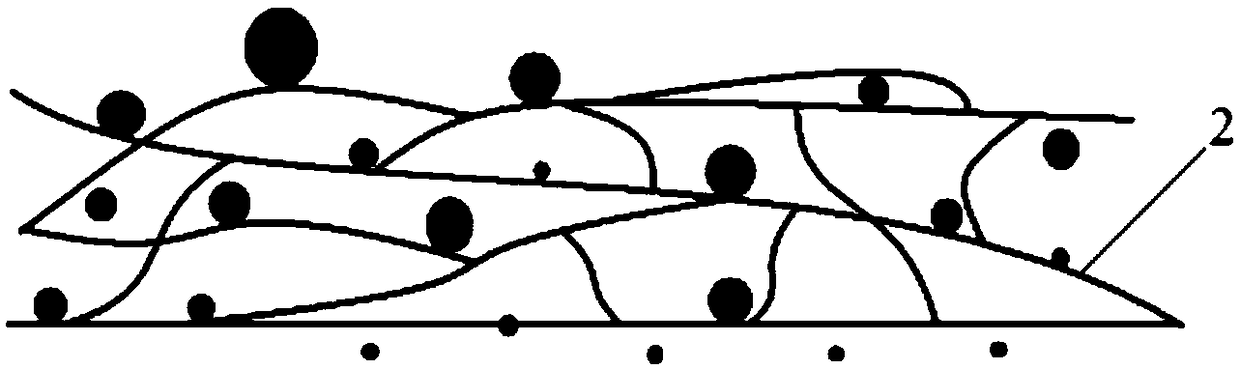

[0029] Such as figure 1 As shown, a filter material with a smoke removal function provided in this embodiment includes a non-woven fabric layer 1, a melt-blown cloth layer 2, an activated carbon cloth layer 3 and a substrate layer 4 stacked in sequence;

[0030] Activated carbon cloth layer 3 contains activated carbon composition, and activated carbon composition comprises:

[0031] Acid gas removal coconut shell charcoal 30%;

[0032] In addition to alkaline gas coconut shell charcoal 20%;

[0033] Activated carbon 50% with CTC greater than 70%.

[0034] Among them, the surface density of coconut shell carbon for acid gas removal is 90g / m 2 , except for alkaline gas, the surface density of coconut shell carbon is 60g / m 2 , The specific surface area of activated carbon with CTC greater than 70% is 150g / m 2 .

[0035] The specific surface area of coconut shell carbon for acid gas removal is 1400m 2 / g, and the coconut shell charcoal for acid gas removal includes coco...

Embodiment 2

[0044] Such as figure 1 As shown, a filter material with a smoke removal function provided in this embodiment includes a non-woven fabric layer 1, a melt-blown cloth layer 2, an activated carbon cloth layer 3 and a substrate layer 4 stacked in sequence;

[0045] Activated carbon cloth layer 3 contains activated carbon composition, and activated carbon composition comprises:

[0046] Acid gas removal coconut shell charcoal 25%;

[0047] In addition to alkaline gas coconut shell charcoal 22%;

[0048] Activated carbon with CTC greater than 70% 53%.

[0049] Among them, the surface density of coconut shell charcoal for acid gas removal is 95g / m 2 , except for alkaline gas, the surface density of coconut shell carbon is 65g / m 2 , The specific surface area of activated carbon with CTC greater than 70% is 130g / m 2 .

[0050] The specific surface area of coconut shell carbon for acid gas removal is 1200m 2 / g, and coconut shell charcoal for acid gas removal includes coconu...

Embodiment 3

[0059] Such as figure 1 As shown, a filter material with a smoke removal function provided in this embodiment includes a non-woven fabric layer 1, a melt-blown cloth layer 2, an activated carbon cloth layer 3 and a substrate layer 4 stacked in sequence;

[0060] Activated carbon cloth layer 3 contains activated carbon composition, and activated carbon composition comprises:

[0061] Acid gas removal coconut shell charcoal 35%;

[0062] Alkaline gas coconut shell charcoal 17%;

[0063] Activated carbon with CTC greater than 70% 48%.

[0064] Among them, the surface density of coconut shell charcoal for acid gas removal is 85g / m 2 , except for alkaline gas, the surface density of coconut shell carbon is 55g / m 2 , The specific surface area of activated carbon with CTC greater than 70% is 170g / m 2 .

[0065] The specific surface area of coconut shell carbon for acid gas removal is 1400m 2 / g, and the coconut shell charcoal for acid gas removal includes coconut shell cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com