Mutton processing equipment

A technology for processing equipment and mutton, which is applied in meat processing equipment, processed meat, meat tenderization, etc., can solve the problems of secondary pollution, peculiar smell, and affect the appearance, so as to reduce the probability of secondary pollution and reduce pollution. probability, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

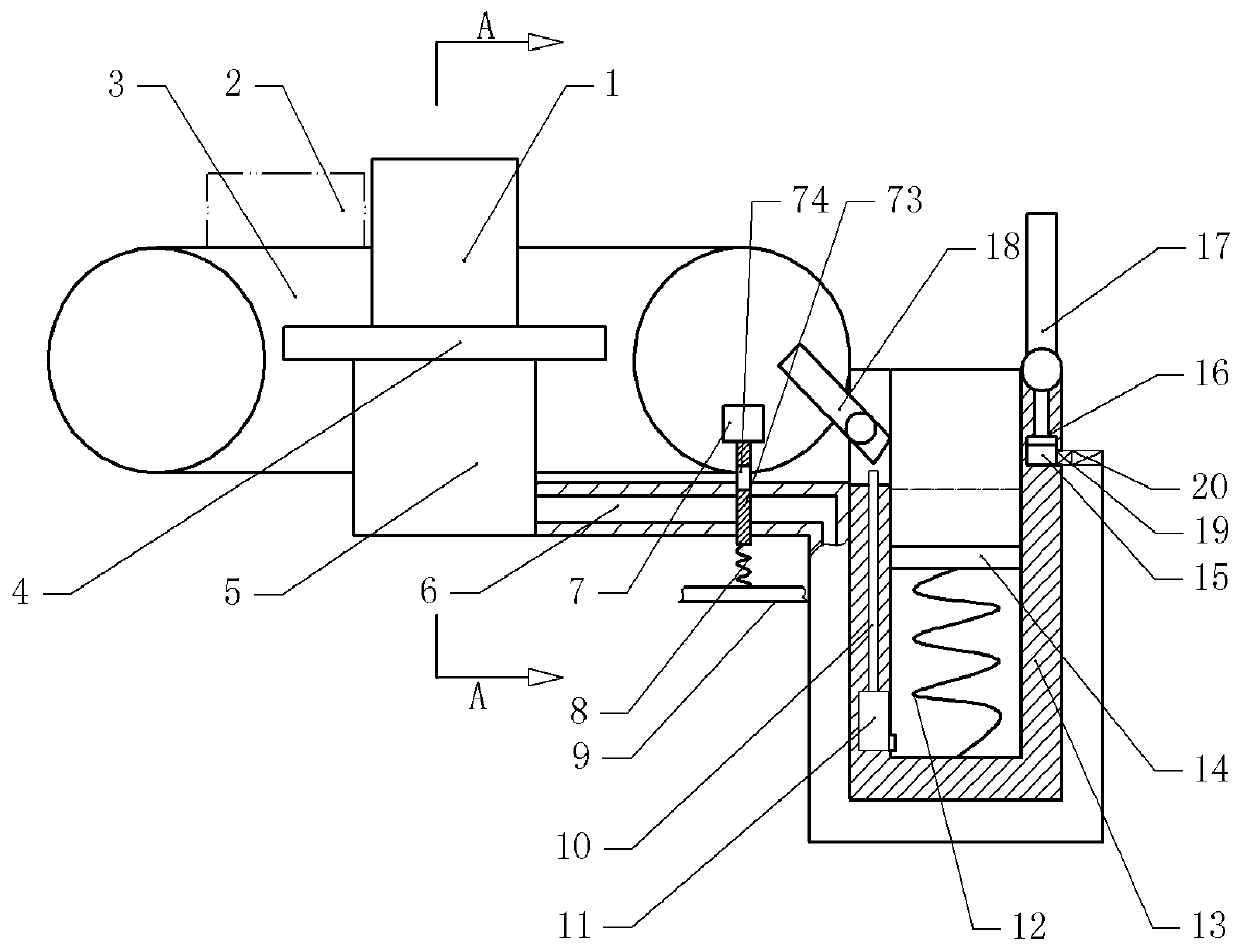

[0027] Basic as attached figure 1 As shown, a mutton processing equipment includes a frame 9 and a transmission mechanism installed on the frame 9, the transmission mechanism includes a conveyor belt 3, a driving roller and a driven roller, the driving roller and the driven roller are connected by the conveyor belt 3, and the driving roller Located on the left side of the conveyor belt 3, the driven roller is positioned on the right side of the conveyor belt 3, the driving roller is driven by a motor, and the driving roller drives the driven roller through the conveyor belt 3.

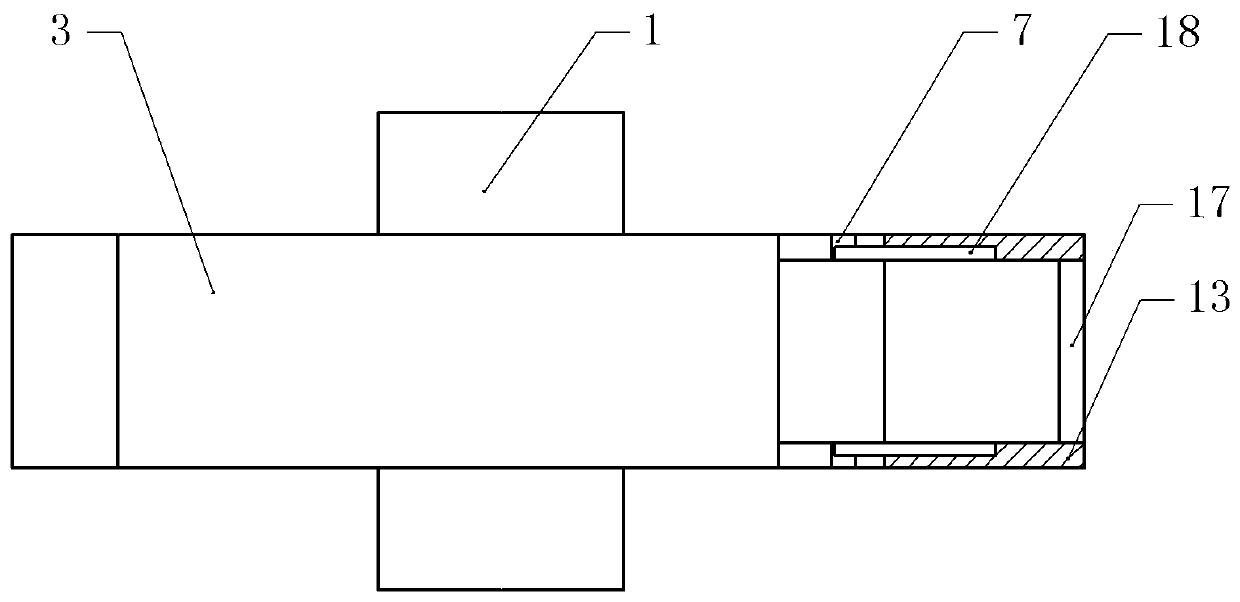

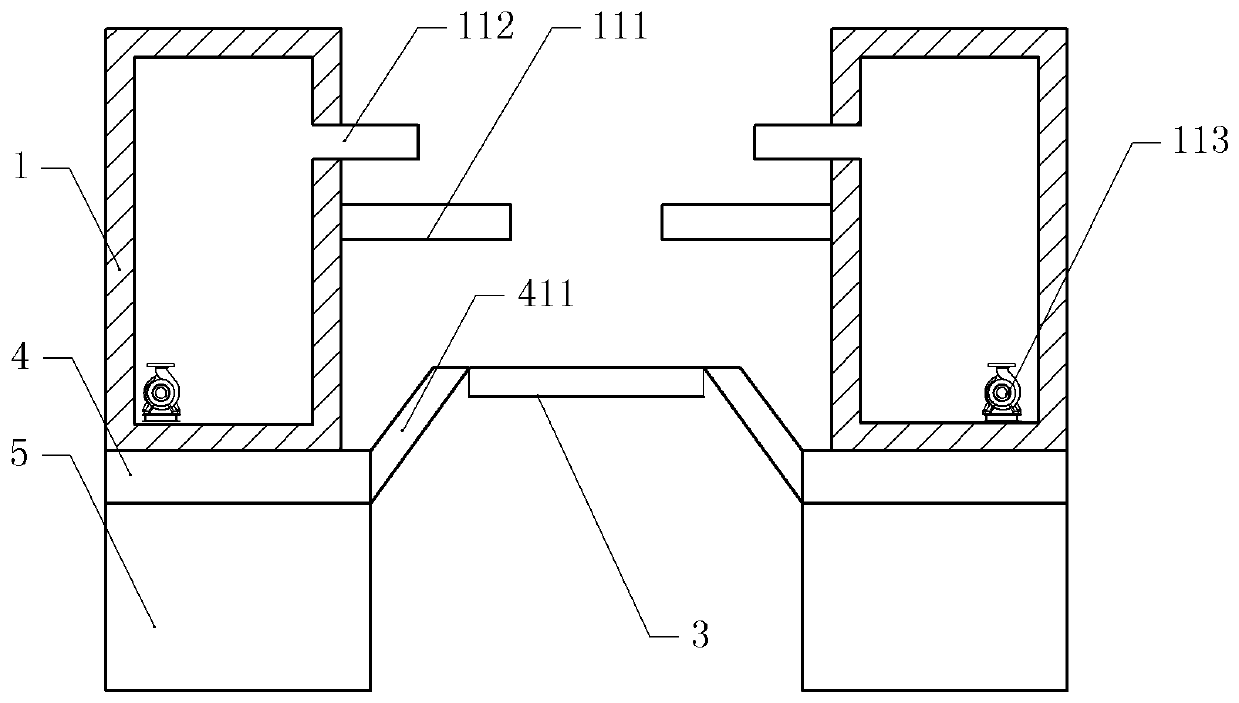

[0028] as attached figure 2 As shown, a cleaning mechanism is provided on both sides along the width direction of the conveyor belt 3, and the cleaning mechanism includes a cleaning box 1 fixed on the frame 9, as attached image 3 As shown, the bottom of the cleaning tank 1 is provided with a support frame 4 fixed on the frame 9, the bottom of the support frame 4 is fixed with a waste water tank 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com